Understanding the dynamics of fencing mesh prices is essential for both seasoned contractors and first-time buyers. This insight not only ensures cost-effective purchasing decisions but also enhances overall project execution. In today's competitive market, price considerations extend beyond initial purchase costs to involve long-term durability and utility.

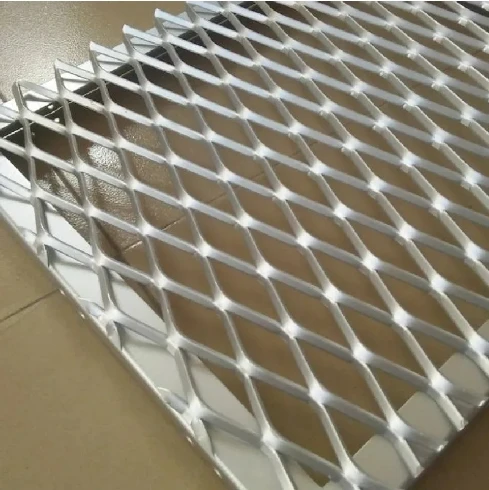

Fencing mesh, known for its versatility and utility across multiple sectors, sees frequent use in agriculture, construction, and security. The primary driver for its price is material composition. The most common materials are galvanized steel, PVC-coated wire, and stainless steel, each offering different benefits and price points. Galvanized steel is often preferred for its rust resistance and cost-effectiveness, while stainless steel is prized for its superior durability and resistance to corrosion over time, albeit at a higher price.

Another significant factor influencing fencing mesh prices is mesh size and customization. Finely woven meshes generally cost more due to the greater amount of material used and the complexity of the manufacturing process. Similarly, custom sizes or specifications that diverge from standard options might attract additional charges, reflecting the bespoke manufacturing requirements.

Advancements in technology and manufacturing techniques also play a role in pricing dynamics. As production processes become more efficient, costs can decrease, potentially lowering prices for end consumers. However, technology can also lead to the introduction of high-end products with enhanced features such as increased durability or ease of installation, commanding higher prices.

Geographical location impacts fencing mesh prices as well. Transportation costs, local demand, and the availability of raw materials can cause price variations. Import tariffs and taxes might also affect prices in regions reliant on imported materials. Buyers in urban areas might face different pricing compared to those in rural settings due to these logistical considerations.

fencing mesh price

Market supply and demand dynamics are unavoidable price influencers. In times of high demand, such as during peak building seasons, prices might surge due to limited availability. Conversely, during off-peak times, prices might drop as suppliers reduce stock to stimulate sales.

From an expert's perspective, long-term value should be a central consideration for buyers. While initial costs are a crucial factor, evaluating the lifespan and maintenance requirements of the fencing mesh is equally important. Lower-priced options may require more frequent replacements, leading to higher long-term costs when compared to initially more expensive, but durable, materials.

Trustworthiness in acquiring fencing mesh involves choosing reputable suppliers with a proven track record. Established suppliers often provide verifiable product specifications and reliable customer support, essential for resolving any post-purchase issues. Online reviews and recommendations from industry professionals can be invaluable in identifying such suppliers.

Overall, comprehending fencing mesh prices involves an interplay of material choice, manufacturing innovations, market fluctuations, and supplier reliability. By considering these factors, buyers can achieve a balance between cost and quality, ensuring their fencing solutions not only fit their budget but also meet their long-term needs efficiently.