I’ve walked too many sites where a “temporary barrier” tried to do a permanent job. If you’re weighing a modern Explosion proof wall for critical infrastructure, the good news is the category has quietly matured. Vendors now blend modular military-style bastions with industrial QA, which—honestly—was overdue. Origin stories matter too: this product line is manufactured in Hebei Province (East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City), a region that’s become a hub for heavy-gauge, hot-dip galvanized fabrication.

Demand is shifting from fixed poured-concrete to modular, fill-on-site units. Why? Logistics and speed. Oil & gas operators, utility substations, and even data centers (yes, really) want rapid deploy, reconfigurable protection that still meets recognized blast guidance. Many customers say the newer fabric liners resist UV far better than five years ago, and it seems that QA is catching up: better weld consistency, thicker zinc layers, documented test reports. To be honest, that paperwork makes procurement teams sleep at night.

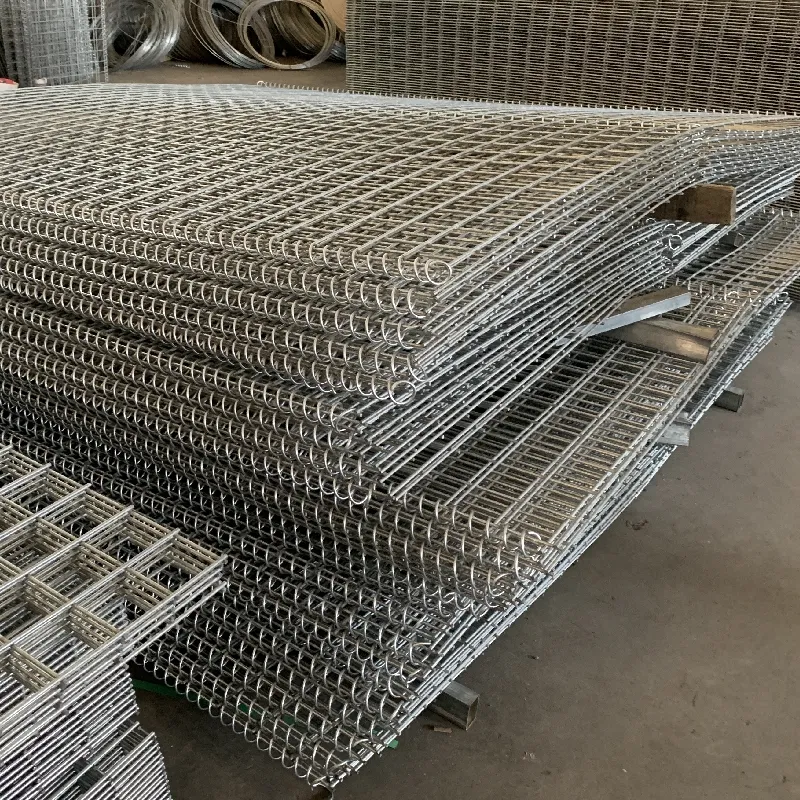

The Explosion proof wall here is a defensive bastion concept—wire mesh cells + geotextile liners, filled with local aggregate. Think Hesco-style, but tuned for industrial sites. The manufacturer describes it as a “Defensive bastion” using a combined approach: high-tensile mesh + non-woven liner + corrosion-resistant finish.

| Parameter | Typical Spec (≈ / real-world may vary) |

|---|---|

| Mesh material | Q235/Q345 steel wire, hot-dip galvanized (ISO 1461) |

| Zinc coating | ≈ 70–100 μm (salt-spray tested to 480–720 h) |

| Liner | UV-stabilized non-woven geotextile, 200–300 g/m² |

| Typical cell size | 1.0–1.5 m (L) × 1.0 m (W) × 1.0–2.0 m (H); modular |

| Blast reference | Validated via shock-tube tests referencing UFC 3-340-02 methods; sample results up to 0.8–1.2 bar reflected |

| Service life | ≈ 15–25 years (rural), 10–15 years (coastal/industrial) with maintenance |

Materials: high-tensile steel wire is welded into panels, hot-dip galvanized per ISO 1461, then formed into collapsible cells. Liners are stitched and riveted. Methods: factory jigs keep mesh square; QA checks weld shear and coating thickness. Testing: representative modules undergo shock-tube or arena tests with pressure gauges following UFC 3-340-02 calculation methods; some clients also request EN 13123/13124-2 style overpressure verification. Typical data shared with us: no liner tear-through and stable deformation under ≈0.9 bar reflected on a 1 m-high section. Certifications: ISO 9001 QMS; material COCs; optional third-party witnessing. Helpful, actually.

Heights 1–3 m, variable cell lengths, HDG or Zn-Al coating, heavy liners for shrapnel, and pre-attached geogrid for soft soils. Colorized liners (beige/green/gray) aren’t just cosmetic—they help heat load, surprisingly.

| Vendor | Key strengths | Certs | Lead time |

|---|---|---|---|

| TIKE Metal (Hebei) | Thick HDG, modularity, shock-tube data shared | ISO 9001; material COC | ≈ 2–4 weeks ex-works |

| Regional Fabricator A | Fast local support; custom heights | ISO 9001 | 1–3 weeks, limited volumes |

| Import OEM B | Aggressive pricing | Varies | 4–8 weeks, batch-based |

Case 1 (Midstream site): 120 m run, 2 m high; post-commissioning verification showed ≤15 mm permanent mesh deformation at ≈0.7 bar reflected—well within the design envelope. Case 2 (BESS yard): operators liked the quieter install—no concrete trucks, less dust. Case 3 (mine pit perimeter): added geogrid saved rework on soft subgrade. Customers say the pallets arrive tidy; I guess that sounds small, but it saves labor.

Caveat: any Explosion proof wall is only as good as the fill and the site prep. Use graded aggregate, compact in lifts, and have a competent engineer sign off against local blast scenarios and prevailing standards.

References

RELATED PRODUCTS