If you work around refineries, battery plants, or munitions depots, you already know the stakes. Overpressure waves don’t negotiate. That’s why I’ve been following the evolution of the Explosion proof wall closely—particularly the modular, fillable “defensive bastion” style that contractors keep asking me about. In the field, speed and predictability matter more than beauty, and this category delivers both, to be honest.

Three forces are pushing specifiers toward modular Explosion proof wall systems: fast expansion of energy storage (hello, gigafactories), brownfield petrochem retrofits that can’t shut down for months, and more stringent risk audits. Many customers say the “temporary-to-permanent” flexibility—build it fast, then upgrade—has been a quiet game-changer.

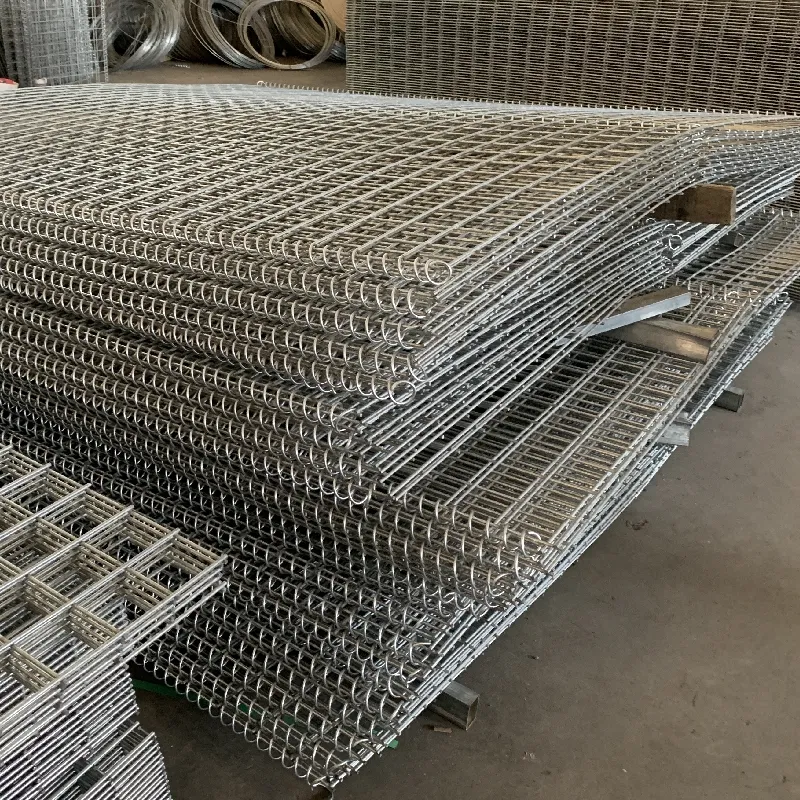

This defensive-bastion concept combines welded steel mesh cages with a geotextile liner; you fill the cells with sand, gravel, or local aggregate. It’s simple, but not simplistic. The better units use hot-dip galvanized wire to EN ISO 1461 with robust welds and stitched liners that resist tearing at corners. Typical process flow:

| Product | Explosion proof wall (defensive-bastion modular) |

| Module size | Length 1–2 m; Height 1–2 m; Depth 0.8–1.2 m (custom on request) |

| Steel mesh & coating | Welded wire ≈4–5 mm; hot-dip galvanized to EN ISO 1461 |

| Liner | PP/PE geotextile ≈300–450 gsm; UV-stabilized |

| Infill | Sand, local gravel, or engineered aggregate (graded) |

| Blast design basis | Project-specific analysis per UFC 3-340-02 / EN 1991-1-7; typical systems used around 30–100 kPa reflected overpressure with proper standoff |

| Indicative factory tests | Weld shear ≥≈4.5 kN (sample); coating thickness ≈70–85 μm; salt spray to ASTM B117 (hours vary by batch) |

| Origin | East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province |

Advantages people mention: fast deployment, local infill (lower logistics), modular repairs, and predictable behavior under accidental actions. The latest Explosion proof wall modules also accept fence toppings and cable trays—nice touch.

| Vendor | Lead time | Customization | Docs & tests |

|---|---|---|---|

| TiKe Metal | ≈2–5 weeks (config-dependent) | Sizes, liners, coatings, accessories | Drawings, weld tests, coating reports; design notes to UFC/EN |

| Vendor A | ≈4–8 weeks | Limited heights | Basic mill certs |

| Vendor B | Project-by-project | Bespoke only (higher cost) | Third-party tests on request |

You can tailor the Explosion proof wall height/width, wire gauge, liner weight, and anti-corrosion system. Common add-ons: top rails for fencing, drainage weeps, earthing lugs, and cable management. For high-humidity sites, many spec Galfan or heavier zinc.

One battery plant team told me installation ran 20% faster than their concrete option, mostly because local aggregate was on-site (no rebar delays). Another refinery used a staged build—temporary Explosion proof wall during turnaround, then reconfigured modules into permanent shielding. It seems that flexibility was worth more than they expected.

Look for submittals aligning with UFC 3-340-02 (blast design), NFPA 68 (venting considerations), API RP 752 (facility siting), and EN 1991-1-7 (accidental actions). Coatings to EN ISO 1461 and factory QA to ISO 9001 are pretty standard asks. To be honest, the best projects loop a structural/blast consultant in early.

References:

RELATED PRODUCTS