Welded wire fencing is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products.

This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

Welded Wire Fencing Overview

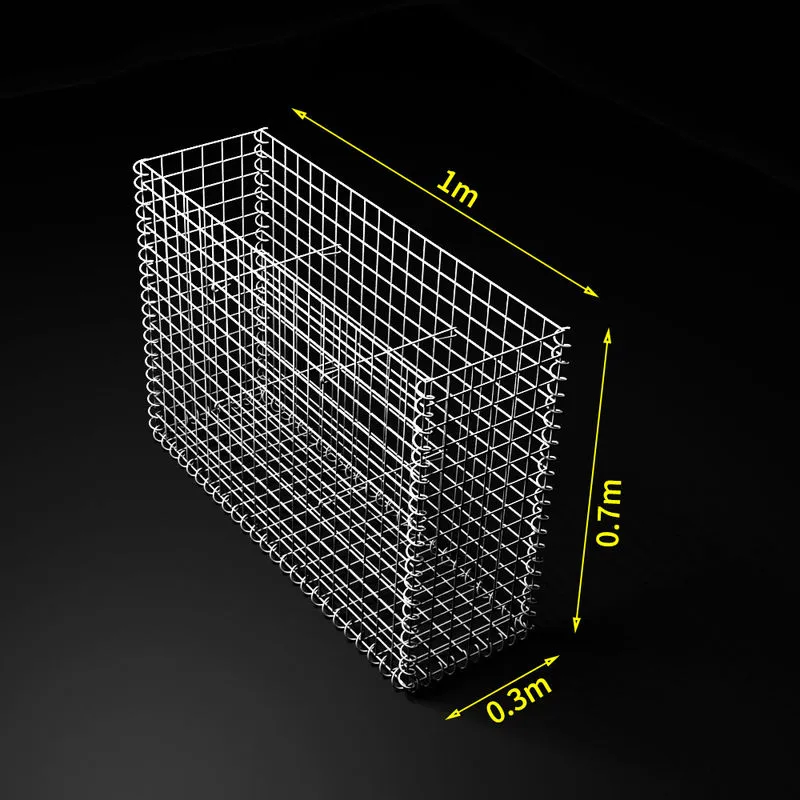

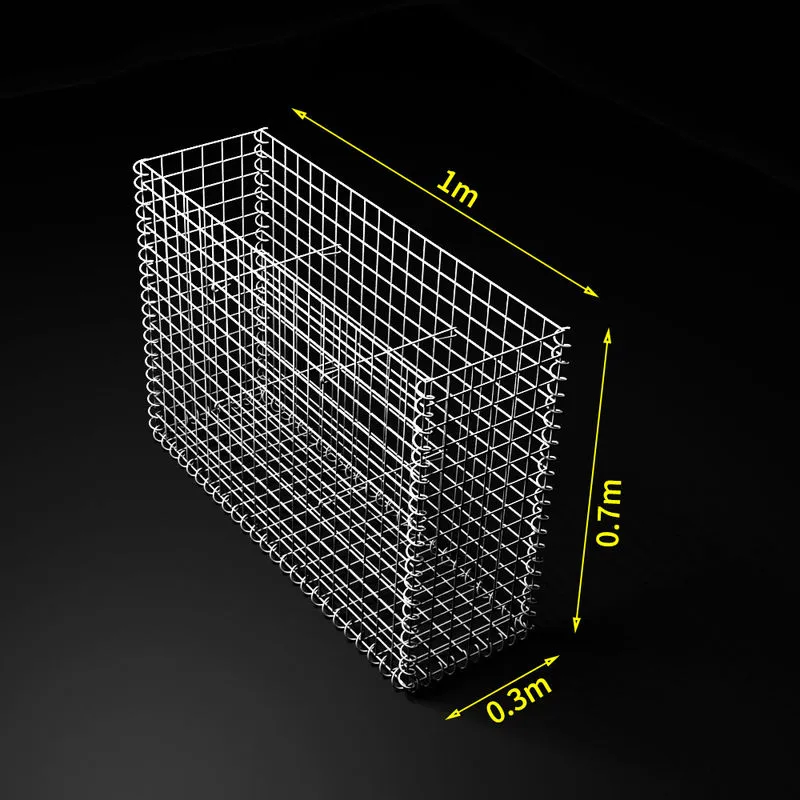

Welded wire fencing, often referred to as weld mesh or welded fence, is an indispensable component in the modern manufacturing landscape, particularly within the Fabricated metal products sector. This versatile product is created by precisely welding intersecting wires, forming a robust and consistent grid pattern. Its strength and stability make it superior to woven alternatives for many industrial applications. In the Manufacturing of metal wire ropes and their products industry, for instance, a reliable welded fence is crucial for securing inventory, creating safety barriers around machinery, and even for filtration or screening processes. Technical specifications typically include varying wire gauges, mesh apertures, and material finishes such as galvanized, stainless steel, or PVC coated options, each offering distinct advantages in terms of corrosion resistance and longevity. SHENZHOU TIKE METAL CO., LTD. stands as a trusted manufacturer, providing high-quality welded wire solutions engineered to meet the stringent demands of diverse industrial environments. Our expertise ensures that every batch of weld mesh delivers unparalleled performance and reliability.

Benefits & Use Cases of Weld Mesh in Manufacturing of metal wire ropes and their products

The applications for weld mesh in the Manufacturing of metal wire ropes and their products sector are extensive and critical. For B2B decision-makers, selecting the right types of welded wire fencing means optimizing operations and ensuring safety. Specific use cases include robust machinery guards, preventing accidental contact with dangerous moving parts, and secure enclosures for valuable raw materials or finished wire rope products. Welded fence panels are also ideal for constructing storage shelving, pallet rack enclosures, and perimeter security fencing for manufacturing facilities. The key features that set weld mesh apart are its inherent strength, structural integrity, and excellent visibility, which is vital for monitoring production lines and facility security. SHENZHOU TIKE METAL CO., LTD. leverages extensive experience to produce weld mesh with superior resistance to impact and corrosion, offering a significant competitive advantage. Our products are tailored to withstand the demanding conditions found in metal fabrication and wire product manufacturing, ensuring long-term performance and peace of mind.

Cost, Maintenance & User Experience

When evaluating types of welded wire fencing, B2B decision-makers in the Fabricated metal products sector prioritize total cost of ownership (TCO) and return on investment (ROI). Weld mesh offers a highly cost-effective solution due to its exceptional durability and minimal maintenance requirements. Unlike other fencing options that may sag or deform over time, a high-quality welded fence maintains its structure, reducing the need for frequent repairs or replacements. This longevity translates directly into significant savings over the product's lifespan. Our galvanized and PVC-coated options provide superior corrosion resistance, ensuring the fence stands up to harsh industrial environments, from humid production halls to outdoor storage areas, further extending its service life. Customer feedback from the Fabricated metal products sector consistently highlights the ease of installation and the robust, reliable performance of SHENZHOU TIKE METAL CO., LTD.'s welded wire products. This positive user experience, combined with low lifecycle costs, makes weld mesh an intelligent investment for any manufacturing operation seeking enduring value.

Sustainability & Market Trends in manufacturing

The manufacturing industry is increasingly focused on sustainability and adapting to evolving market trends and regulations. When considering types of welded wire fencing, environmental impact and material sourcing are growing concerns for B2B decision-makers. Welded fence products, particularly those made from steel, are highly recyclable, contributing to a circular economy and reducing waste. Furthermore, their extended lifespan inherently promotes sustainability by minimizing resource consumption for replacements. Current market trends in manufacturing point towards a greater emphasis on enhanced security measures, automated production line safety barriers, and compliance with increasingly stringent industrial safety standards. SHENZHOU TIKE METAL CO., LTD. is at the forefront of these developments, consistently innovating our weld mesh products to not only meet but exceed these evolving demands. We are committed to sustainable manufacturing practices, offering solutions that are both environmentally responsible and deliver high performance, solidifying our position as a forward-thinking and eco-conscious partner in the metal fabrication and wire products industry.

Conclusion on Welded Fence from SHENZHOU TIKE METAL CO., LTD.

In conclusion, the various types of welded wire fencing, including high-quality weld mesh and durable welded fence panels, are indispensable assets for businesses operating within manufacturing, Fabricated metal products, and the Manufacturing of metal wire ropes and their products. These products offer unparalleled strength, security, and versatility, ensuring operational efficiency and long-term value. SHENZHOU TIKE METAL CO., LTD. is dedicated to providing superior welded wire solutions that meet the rigorous demands of industrial applications, backed by our commitment to quality, innovation, and customer satisfaction. Partner with us to enhance the safety, security, and efficiency of your operations with our expertly manufactured products.

Contact us: email: info@tikemetal.com

Visit our website: https://www.tikemetal.com