(expanding metal sheets)

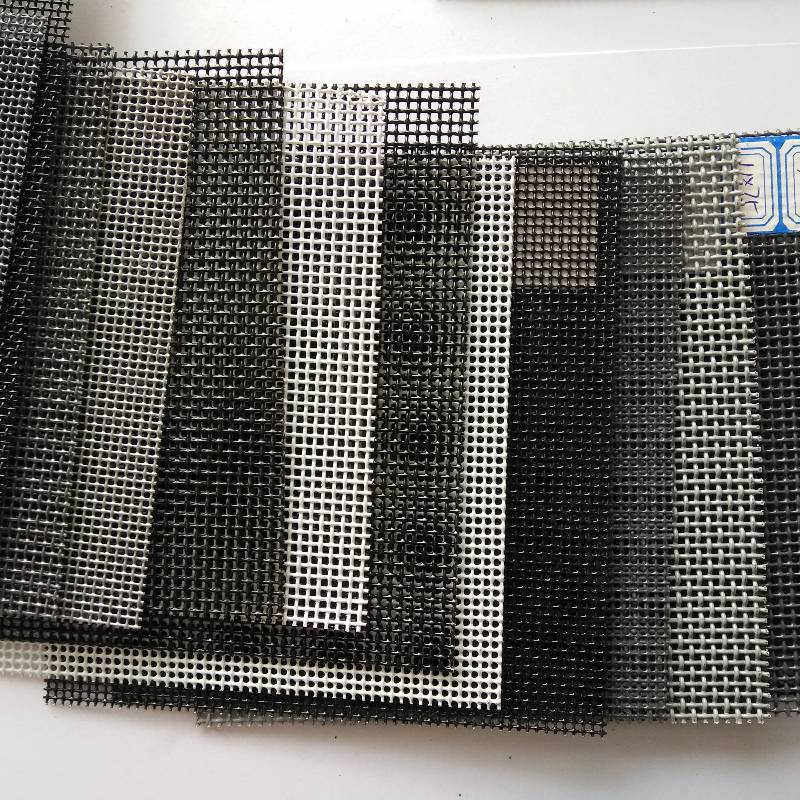

Expanding metal sheets are engineered through a precise slit-and-stretch process, creating lightweight yet durable materials ideal for filtration, facades, and machinery. These sheets offer a unique combination of 40-60% open area, enabling airflow and light penetration while maintaining structural integrity. Industries such as construction, automotive, and aerospace rely on expanding metal sheets

for their adaptability and load-bearing capacity of up to 500 MPa tensile strength.

Advanced manufacturing techniques ensure uniformity in strand thickness (±0.1mm tolerance) and repeatable patterns. Unlike traditional perforated sheets, expanded metal retains material strength by avoiding waste—critical for projects requiring corrosion resistance or high-temperature stability. A 2023 study by the International Materials Institute showed expanded metal sheets reduce component weight by 22-35% compared to solid alternatives, directly lowering transportation and installation costs.

| Manufacturer | Material Range | Thickness (mm) | Max Sheet Size | Lead Time |

|---|---|---|---|---|

| Expanding Metal Co. | Stainless, Aluminum | 0.5–12 | 3m x 10m | 10 days |

| PerforTech Global | Galvanized, Copper | 0.3–8 | 2.5m x 6m | 14 days |

| MetaFlex Industries | Titanium, Alloy | 1–15 | 4m x 12m | 21 days |

Specialized expanding metal companies provide CAD-based customization, with options for diamond, hexagonal, or circular patterns. For instance, a recent skyscraper project in Dubai utilized anodized aluminum sheets with 8mm hexagonal apertures to reduce solar heat gain by 18%. Clients can specify sheet dimensions (±2mm accuracy), edge treatments, and coatings like powder or PVDF for UV protection.

● Automotive: A European EV manufacturer integrated expanded aluminum battery casings, achieving a 27% thermal dissipation improvement.

● Architecture: A New York retrofit project used decorative perforated metal sheets for sunshades, cutting HVAC loads by 15% annually.

● Energy: Oil rig platforms deployed corrosion-resistant expanded titanium sheets, extending service life by 8 years.

Expanding metal production generates 90% less scrap than laser-cutting methods, aligning with circular economy principles. Lifecycle analyses reveal recycled-content sheets lower embodied carbon by 40–60%, while their longevity minimizes replacement frequency. ROI calculations show break-even points within 2–3 years for large-scale installations.

Emerging technologies like AI-driven pattern optimization and nano-coatings are set to enhance expanding metal sheets’ functionality. Research partnerships between academia and leading expanding metal companies aim to develop self-healing surfaces and shape-memory alloys, potentially revolutionizing sectors from smart buildings to biomedical engineering.

(expanding metal sheets)

A: Expanding metal sheets are used for lightweight structural support, ventilation, and decorative applications. They are commonly employed in construction, industrial safety, and architectural design due to their durability and customizable patterns.

A: An expanding metal company tailors sheets by adjusting strand width, thickness, and perforation patterns. Customization ensures the sheets meet specific load-bearing, airflow, or aesthetic requirements for projects like façades or machinery guards.

A: Yes, decorative perforated metal sheets are often made from corrosion-resistant materials like aluminum or stainless steel. They are ideal for both indoor and outdoor use, maintaining durability while enhancing visual appeal.

A: Industries like construction, automotive, and HVAC rely on expanding metal sheets for grating, filtration, and cladding. Their versatility also makes them popular in interior design and security applications.

A: Yes, some decorative perforated metal sheets are designed with acoustic properties to absorb sound. They are used in theaters, offices, and public spaces to combine functionality with modern aesthetics.

RELATED PRODUCTS