Expanded Metal Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how SHENZHOU TIKE METAL CO., LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

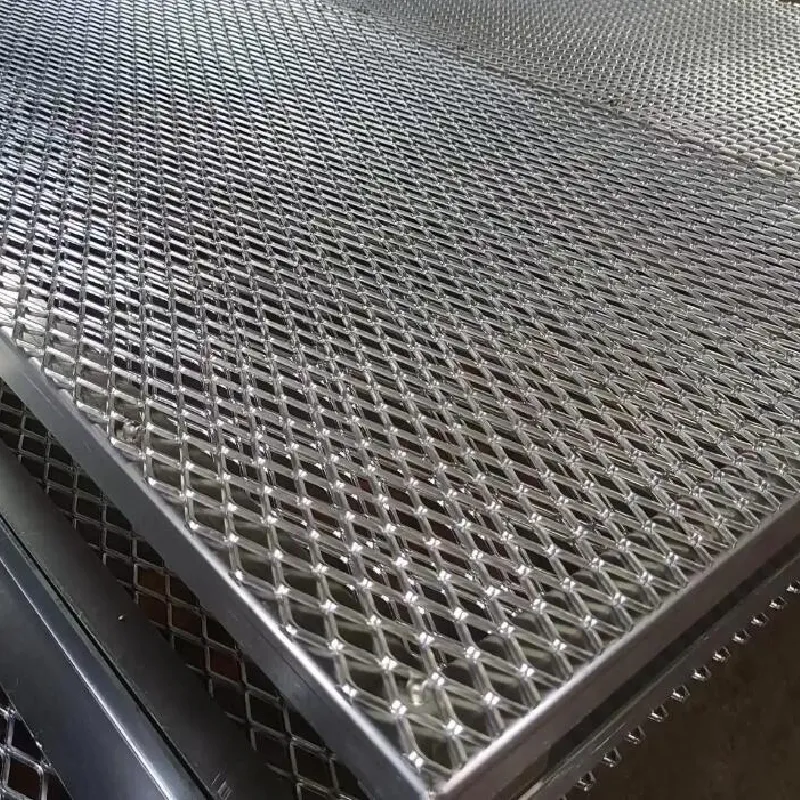

Expanded Metal Mesh is produced by slitting and stretching metal sheet into a unified lattice of diamonds, hexagons, or custom apertures. Unlike welded or woven alternatives, there are no joints to fail—resulting in a monolithic, high-strength, lightweight sheet. In the fabricated metal products segment and the manufacturing of metal wire ropes and their products, this structure offers a robust balance of strength, open area, and airflow for guarding, walkways, trays, and process enclosures.

Typical specifications include strand width (SW) from 0.5–6.0 mm, short-way diamond (SWD) from 2–50 mm, long-way diamond (LWD) from 5–120 mm, and thickness from 0.5–8.0 mm. Materials range from low-carbon steel (black or hot-dip galvanized) to stainless steel (304/316) and aluminum alloys, available in raised (ribbed) or flattened profiles. Surface treatments can include galvanizing, powder coating, or anodizing for enhanced corrosion performance. SHENZHOU TIKE METAL CO., LTD. manufactures Expanded Metal Mesh to order with consistent strand geometry and tight tolerances, enabling repeatable fit-up in OEM assemblies and retrofit projects.

Case in point: a cable manufacturing facility upgraded machine guarding to raised Expanded Metal Mesh to boost airflow around drawing lines. The result was improved heat dissipation and easier visual inspection, while maintaining operator safety and meeting internal safety protocols.

Wire rope production lines rely on dependable guarding, safe access, and efficient material handling. Expanded Metal Mesh delivers in all three areas. For stranding and closing machines, it provides rigid, tamper-resistant guards with high visibility—operators can inspect capstans, bobbins, and payoff reels without removing panels. Around annealing or galvanizing zones, the mesh’s open area supports ventilation while still acting as a barrier. On catwalks and mezzanines, raised patterns add anti-slip traction, critical for areas with lubricants or drawing compounds.

Other common applications include cable trays and sidewalls, partition fencing for raw material storage, protective screens on payoff/take-up units, and safety cages around spooling equipment. Compared with perforated sheet or welded wire, Expanded Metal Mesh offers better strength-to-weight ratio and no welds to crack, plus superior formability for rolled edges and frames. SHENZHOU TIKE METAL CO., LTD. supports tailored geometry—optimizing LWD/SWD for airflow, debris control, or line-of-sight—so OEMs and plant engineers get a mesh that aligns with safety standards, ergonomic access, and maintenance efficiency.

Competitive advantages include rapid lead times on standard patterns, custom panel sizing to reduce on-site cutting, and finish options that extend service life in high-humidity or corrosive environments.

Total cost of ownership for Expanded Metal Mesh is driven by durability, minimal waste, and low maintenance. Because the mesh is expanded from a single sheet, there is no material lost to punching (as with perforated metal), and no welds to inspect or repair over time. In harsh manufacturing zones, galvanized or stainless steel options reduce repainting, corrosion treatments, and unplanned downtime. Flattened mesh offers smoother surfaces for easy cleaning, while raised mesh improves grip where slip hazards exist.

Customers in the fabricated metal products sector report faster installation due to predictable flatness and consistent apertures—panels align cleanly with frames, which reduces field rework. For plant safety managers, the high visibility through Expanded Metal Mesh supports quicker machine checks and lockout/tagout verification. Over a multi-year horizon, these factors translate into measurable ROI through fewer replacements, lower maintenance labor, and improved uptime.

SHENZHOU TIKE METAL CO., LTD. provides engineering support—helping specify strand width, gauge, and coating to meet the required load capacity, open area, and environmental exposure—so procurement teams can balance upfront cost with long-term performance.

Expanded Metal Mesh inherently supports sustainability: the manufacturing process converts sheet into open area without generating punching scrap, maximizing raw material utilization. For facilities pursuing lower carbon footprints, specifying galvanized or aluminum meshes with long service life reduces replacement frequency and associated transport and disposal impacts. End-of-life recyclability further strengthens the sustainability profile.

Regulatory emphasis on machine safety and ventilation is rising across global markets. Expanded Metal Mesh helps satisfy guarding and airflow needs simultaneously—important for heat-generating processes in wire drawing, annealing, or coating. Additionally, trends toward modular factories and rapid line reconfiguration favor components like mesh panels that are easy to cut, frame, and relocate.

SHENZHOU TIKE METAL CO., LTD. aligns with these trends through quality-controlled production, traceable materials, and finish options that meet commonly referenced requirements. The company collaborates with OEMs and end users to standardize panel sizes, reduce material waste in downstream fabrication, and support continuous improvement initiatives on the plant floor.

For B2B decision makers in fabricated metal products and the manufacturing of metal wire ropes and their products, Expanded Metal Mesh offers a rare mix of strength, safety, airflow, and cost efficiency. With customizable apertures, finishes, and profiles, SHENZHOU TIKE METAL CO., LTD. delivers durable, high-performance panels that streamline installation and long-term maintenance.

Contact us: email: info@tikemetal.com

Visit our website: https://www.tikemetal.com

RELATED PRODUCTS