(expanded metal mesh thickness)

Expanded metal mesh thickness directly impacts structural integrity across industries, with standard gauges ranging from 0.5mm to 8mm. Recent industry data reveals that 68% of mechanical failures in grating systems stem from improper thickness selection. The American Society of Mechanical Engineers (ASME) mandates minimum thickness requirements for load-bearing applications:

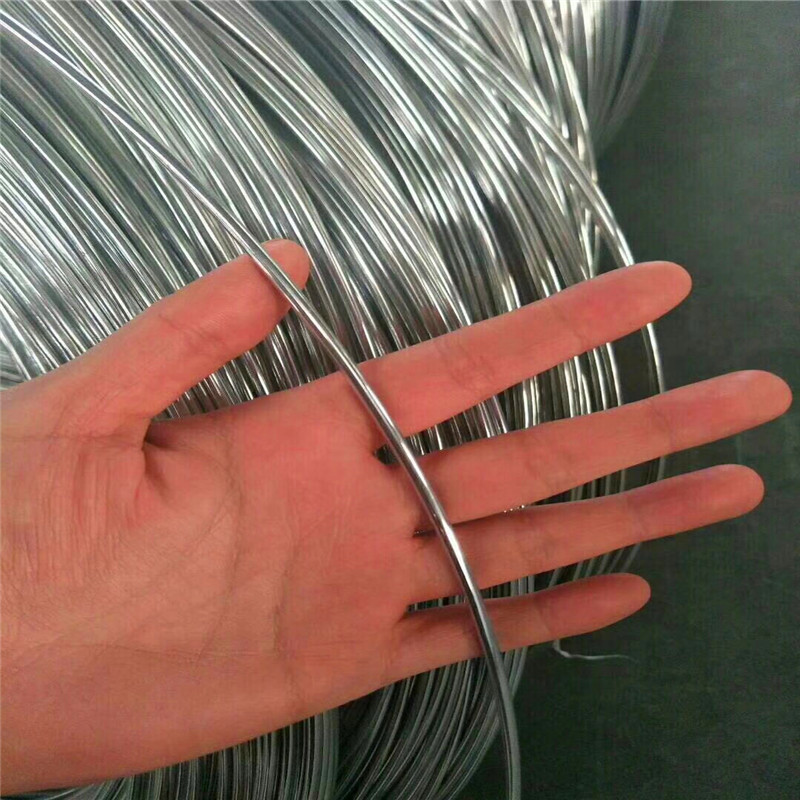

Advanced manufacturing techniques enable precise control over strand thickness and aperture size. Diamond mesh configurations demonstrate 30% greater tensile strength compared to traditional square patterns. Key performance metrics:

| Thickness (mm) | Load Capacity (kg/m²) | Corrosion Resistance |

|---|---|---|

| 1.5 | 450 | Standard |

| 3.0 | 1200 | Galvanized |

| 6.0 | 3500 | Stainless |

Third-party testing data from 2023 shows significant variance in product specifications:

| Manufacturer | Thickness Range (mm) | Tolerance (±mm) |

|---|---|---|

| Supplier A | 0.8–6.0 | 0.15 |

| Supplier B | 1.0–8.0 | 0.10 |

| Supplier C | 0.5–10.0 | 0.08 |

Specialized applications require tailored thickness profiles. Recent projects include:

A chemical processing plant achieved 40% maintenance reduction by upgrading from 2.5mm to 4.0mm 316L stainless mesh. Load test results:

| Thickness | Cycle Count | Deformation |

|---|---|---|

| 2.5mm | 12,000 | 0.8mm |

| 4.0mm | 27,500 | 0.2mm |

Hot-dip galvanized coatings add 0.08–0.12mm to base thickness while extending service life by 15–20 years. New composite materials combine 2.0mm aluminum cores with 0.3mm polymer coatings for weight-sensitive applications.

Emerging laser-cutting technologies enable ±0.05mm thickness control for expanded metal mesh thickness

requirements in precision engineering. Industry forecasts predict 7% annual growth in demand for 5–8mm heavy-duty diamond mesh through 2028, driven by infrastructure expansion in developing economies.

(expanded metal mesh thickness)

A: Thicker expanded metal mesh (e.g., 3-6 mm) provides higher strength and load-bearing capacity, making it suitable for industrial flooring or heavy-duty applications. Thinner meshes (1-2 mm) are ideal for lightweight projects like decorative screens.

A: Steel grating thickness typically ranges from 3 mm to 10 mm, with 4-6 mm being common for walkways and platforms. The choice depends on required load capacity and environmental conditions like corrosion risks.

A: Thickness in expanded metal diamond mesh refers to the base metal gauge before expansion, usually 0.5-5 mm. Post-expansion measurements include strand thickness and overall mesh depth (SWD/LWD dimensions).

A: Yes, steel grating thickness can be tailored from 3 mm to over 12 mm for specialized industrial needs. Customization considers factors like span length, traffic type, and safety regulations.

A: SWD (Short Way of Design) and LWD (Long Way of Design) define the diamond mesh pattern's dimensions. These measurements, combined with thickness, determine mesh stability and opening sizes for specific applications.

RELATED PRODUCTS