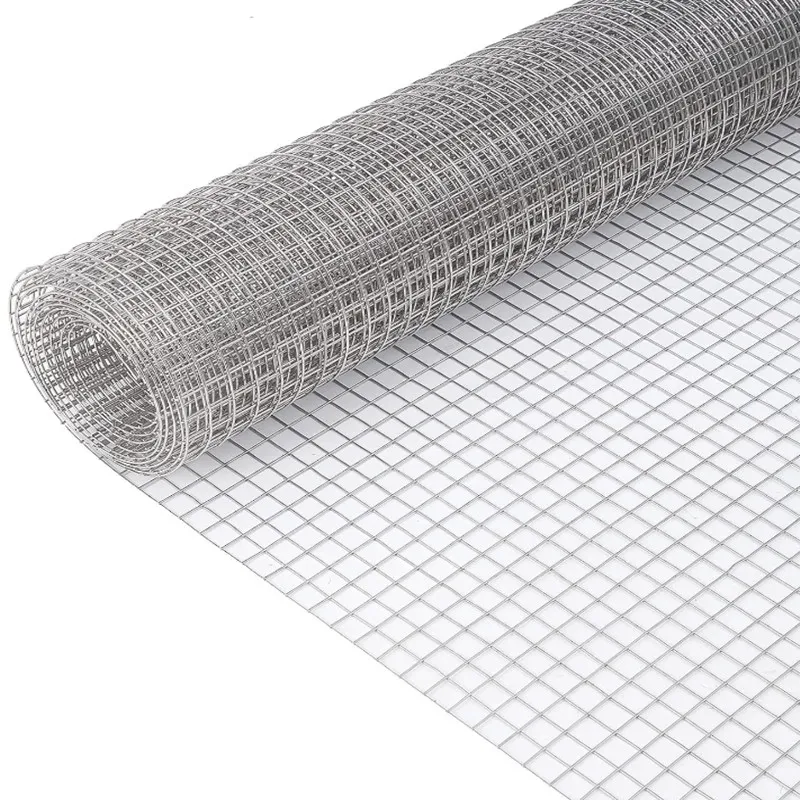

When searching for reliable and versatile materials for construction, manufacturing, or security applications, expanded mesh for sale is an excellent choice. This material is highly valued for its durability, strength, and flexibility. Expanded mesh is created by stretching a metal sheet, creating a pattern of uniform holes throughout the material. It is commonly used in various industries such as fencing, architectural projects, and industrial applications. Whether you need a security barrier, a decorative element, or a heavy-duty screen, expanded mesh for sale provides an affordable solution with various benefits.

Not only does expanded mesh offer significant strength and resistance to wear, but it also has a lightweight structure, making it easy to transport and install. Additionally, the mesh design provides excellent ventilation and drainage, making it suitable for use in both outdoor and indoor environments. With a wide range of sizes, materials, and finishes available, you can easily find the right expanded mesh for sale that meets your specific needs.

Metal Mesh Sheet: The Ideal Choice for a Variety of Applications

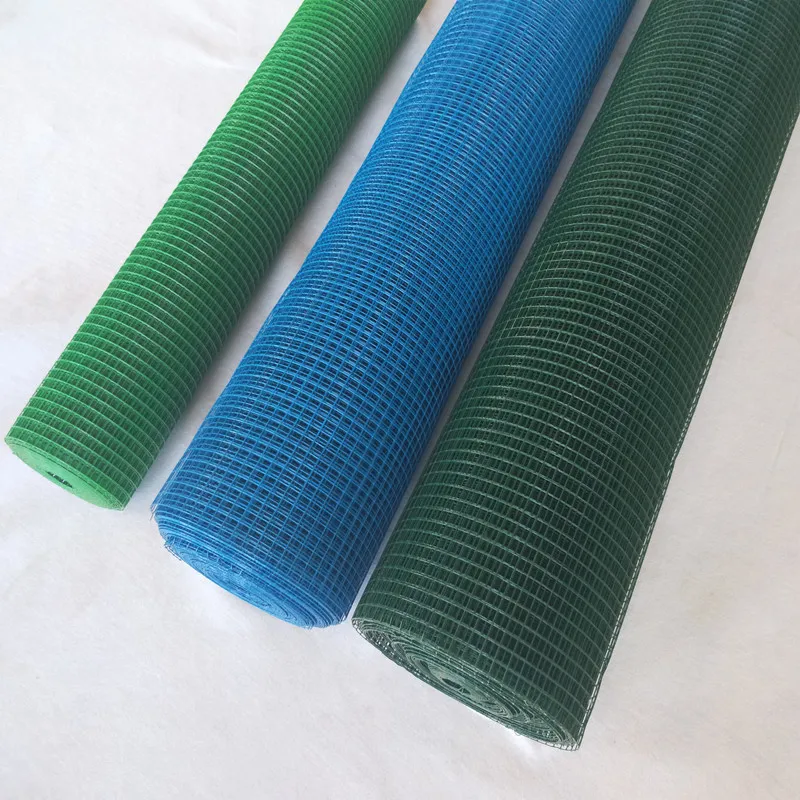

Another popular form of expanded mesh is the metal mesh sheet. These sheets are available in a range of sizes, materials, and thicknesses to meet the demands of various industries. The metal mesh sheet is commonly used for applications requiring strength, durability, and flexibility. Its versatile design allows for use in construction, industrial safety, filtration, and many other fields.

Made from various metals, such as steel, aluminum, or stainless steel, metal mesh sheets are ideal for creating barriers, screens, and enclosures. The combination of their durability and aesthetic appeal also makes them an attractive option for architectural projects, where they can be used to enhance the visual appeal of a structure while maintaining practicality. Whether you are looking for a mesh sheet for your factory, warehouse, or office, metal mesh sheets are designed to meet diverse requirements.

Fine Stainless Steel Mesh: Offering Strength and Precision

For more specific and precise applications, fine stainless steel mesh offers an ideal solution. Unlike standard mesh, fine stainless steel mesh is designed to provide a higher level of filtration and protection, making it perfect for applications that demand finer levels of accuracy. This type of mesh is typically used in industries like food processing, pharmaceutical production, and water filtration, where cleanliness and safety are of utmost importance.

The stainless steel construction ensures that fine stainless steel mesh is resistant to corrosion, rust, and staining, making it highly durable even in harsh environments. Additionally, it offers excellent mechanical strength and resistance to wear, allowing it to perform well under pressure. Fine stainless steel mesh also has superior resistance to high temperatures, which is crucial for applications that involve heat exposure. This combination of qualities makes it an excellent option for anyone seeking high-quality mesh for intricate or sensitive applications.

316 Stainless Steel Mesh Screen: A Premium Option for Tough Environments

If you need a mesh that can withstand extreme conditions, 316 stainless steel mesh screen is the premium choice. Made from a high-quality stainless steel alloy that contains molybdenum, 316 stainless steel mesh screen offers enhanced resistance to corrosion, especially in saltwater and chloride-rich environments. This makes it particularly suitable for marine and coastal applications, as well as in industries such as chemical processing, pharmaceuticals, and food production.

The exceptional durability and corrosion resistance of 316 stainless steel mesh screen ensure that it maintains its integrity and performance, even when exposed to harsh weather conditions or aggressive chemicals. The fine mesh openings make it ideal for applications requiring filtration, security, and separation of materials. Whether used as a protective screen, a filtration device, or a structural element, 316 stainless steel mesh screen offers an unparalleled level of performance and longevity.

Measuring Expanded Metal: How to Choose the Right Size and Shape

When working with expanded metal, it’s essential to understand how to accurately measure the material to ensure that it meets your specific needs. Measuring expanded metal involves determining the size and spacing of the openings, the thickness of the metal, and the overall dimensions of the sheet. These factors are crucial for determining the strength, durability, and application of the mesh.

To properly measure expanded metal, you need to consider both the strand width (the thickness of the metal itself) and the opening size (the gap between the strands). Additionally, the overall dimensions of the sheet must be taken into account. For instance, if you are using expanded metal for a security fence, you will need to ensure that the openings are small enough to prevent unauthorized access while still allowing for proper ventilation. Understanding measuring expanded metal ensures that you select the appropriate size and design for your project, providing maximum performance and efficiency.

Expanded Mesh and Stainless Steel Mesh FAQs

What is the difference between expanded mesh and regular mesh?

Expanded mesh is made by cutting and stretching a metal sheet to create a pattern of holes, whereas regular mesh is often woven or welded. Expanded mesh offers greater strength and durability while maintaining a lightweight structure, making it ideal for a variety of applications.

What is the best application for fine stainless steel mesh?

Fine stainless steel mesh is best used in applications that require high levels of filtration or protection, such as in food processing, water filtration, or the pharmaceutical industry.

Why is 316 stainless steel mesh screen considered superior?

316 stainless steel mesh screen is considered superior due to its excellent corrosion resistance, particularly in saltwater and chemically harsh environments. It is perfect for marine applications, food processing, and chemical industries.

How do I measure expanded metal for my project?

To measure expanded metal, you need to determine the strand width, the size of the openings, and the overall dimensions of the sheet. This will ensure that the mesh fits the specific requirements of your project.

What are the benefits of purchasing expanded mesh for sale?

Purchasing expanded mesh for sale offers an affordable and versatile solution for a variety of applications. It is durable, easy to handle, and can be used in multiple industries such as construction, security, and industrial applications.