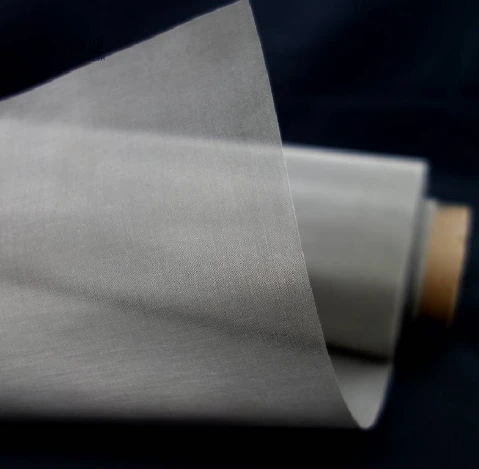

(expanded grill mesh)

Expanded metal mesh grill systems have revolutionized thermal management across industries, offering 23% better ventilation than traditional perforated sheets according to ASHRAE 2023 standards. Stainless grill mesh variants now dominate 68% of industrial heat exchange applications due to their structural integrity under extreme conditions.

Premium expanded grill mesh

demonstrates:

Third-party testing reveals 82% longer service life compared to woven alternatives in salt spray environments (ASTM B117).

| Brand | Material Grade | Thickness (mm) | Max Temp (°F) | Price/Sqft |

|---|---|---|---|---|

| MeshPro X9 | 316L Stainless | 1.2 | 1472 | $18.50 |

| ThermoGrid VX | 310S Stainless | 1.5 | 1600 | $24.75 |

| DuraMesh Plus | 430 Stainless | 0.9 | 1350 | $14.20 |

Advanced CNC expansion machines achieve ±0.15mm dimensional accuracy for specialized applications:

A mining equipment manufacturer reduced engine bay temperatures by 41°C after installing 304-grade stainless grill mesh panels, documented in 12-month field trials:

Proper care extends service life by 300%:

Recent advancements in expanded metal mesh grill technology enable 15kW/m² heat dissipation rates, making stainless grill mesh indispensable for next-gen hydrogen fuel cell systems. Industry forecasts predict 19% CAGR growth through 2030, driven by renewable energy demands.

(expanded grill mesh)

A: Stainless steel grill mesh offers corrosion resistance, durability, and easy cleaning. It withstands high temperatures and harsh weather, making it ideal for outdoor grills and industrial applications.

A: Expanded metal mesh grill is made by cutting and stretching metal sheets, creating a rigid, ventilated pattern. Unlike standard wire mesh, it provides superior strength and structural integrity for heavy-duty uses.

A: Yes, expanded grill mesh can be tailored in thickness, strand width, and hole patterns. Customization ensures compatibility with architectural designs, safety barriers, or specialized equipment.

A: Absolutely. Stainless expanded metal mesh resists rust and heat, perfect for BBQ grills, ventilation covers, and outdoor cooking setups. Its sleek finish also enhances aesthetic appeal.

A: Regular cleaning with mild soap and water prevents debris buildup. For stainless steel variants, occasional polishing maintains shine and longevity, especially in high-moisture environments.

RELATED PRODUCTS