Electro galvanized welded wire mesh has emerged as a staple across various industries, prominently due to its enhanced durability, superior construction quality, and adaptability to different environmental conditions. Unlike its traditional non-galvanized counterparts, electro galvanized wire meshes are coated with a layer of zinc which effectively protects the underlying steel, significantly extending the material's lifespan and performance under adverse conditions.

The galvanization process involves immersing the welded wire mesh in a zinc solution, allowing the zinc to form a robust coating that offers corrosion resistance. This meticulous process is critical, especially in regions prone to humidity or salt exposure, as these conditions can accelerate rust formation. By using electro galvanized welded wire mesh, industries can ensure a longer-lasting and low-maintenance solution, reducing operational costs over time.

In the agricultural sector, these meshes provide an indispensable tool for creating sturdy enclosures, protecting livestock and crops from predators while withstanding the wear and tear of weather changes. The uniform grid pattern of the wire mesh is not only aesthetically pleasing but provides the necessary strength to resist impact and deformation. When choosing mesh sizes, farmers can select from a range of options depending on their specific needs—fine meshes to keep out small pests or larger openings for enhanced visibility and access.

Construction and infrastructure projects rely heavily on electro galvanized welded wire meshes for reinforcement purposes. Whether used in concrete reinforcement or as a framework for architectural projects, the added zinc coating ensures that the mesh maintains its structural integrity over long periods. This is especially critical for construction in coastal areas where the high presence of salt could greatly compromise structural materials. The durability of these meshes translates directly into fewer repairs and replacements, leading to more sustainable and cost-effective building practices.

In the realm of industrial applications, electro galvanized welded wire mesh plays a vital role in ensuring safety and efficiency. Factories and warehouses utilize these meshes for forming protective barriers around equipment and hazardous zones, preventing accidents while maintaining visibility and airflow. The combination of high tensile strength and flexibility makes electro galvanized wire mesh an ideal choice for customizable solutions, adaptable to any spatial requirement or safety regulation.

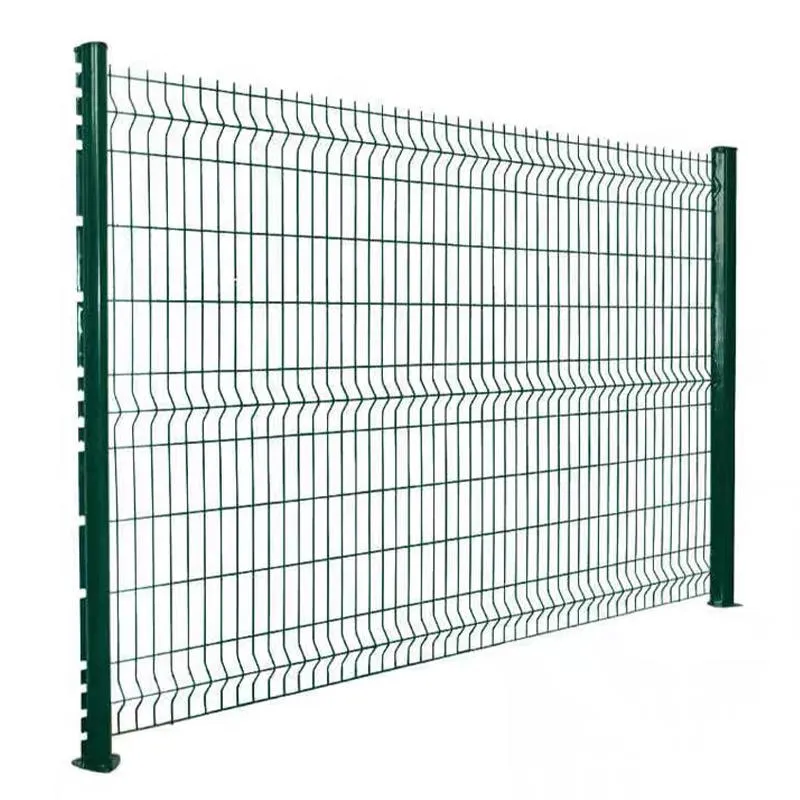

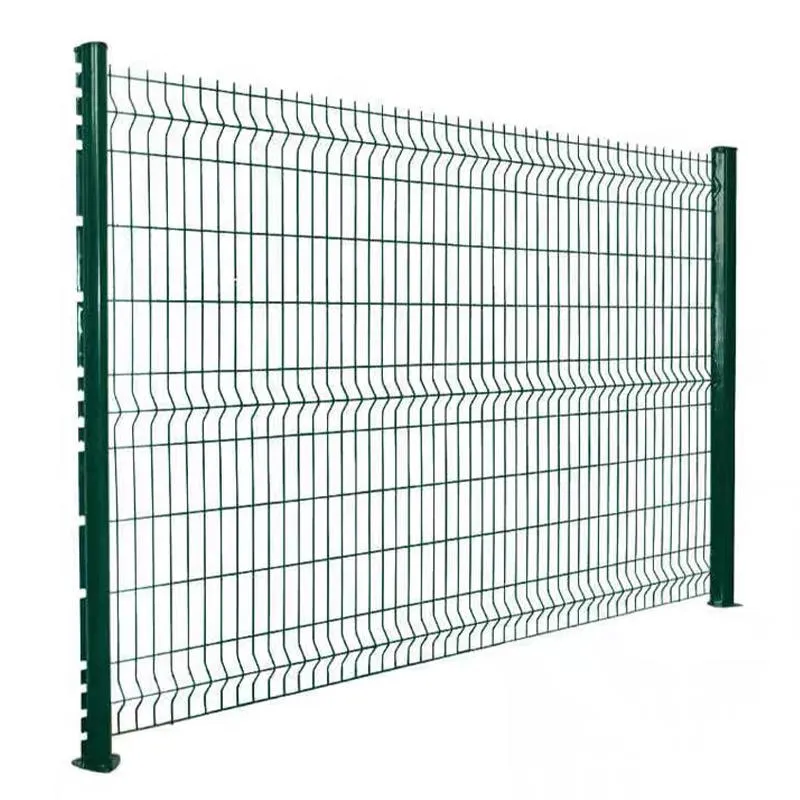

electro galvanized welded wire mesh

This wire mesh also stands out in the realm of design and architecture. While primarily functional, its clean, geometric lines have inspired artists and architects alike to explore its potential in modern design. From creating partitions in office spaces to adding texture and interest in exterior façades, the material provides both functional partitioning and an expressive design statement.

From an environmental standpoint, electro galvanized welded wire mesh is a more sustainable option compared to plastics or other materials that may release toxins. The recyclability of steel further enhances its appeal to eco-conscious industries seeking to minimize their carbon footprint. Additionally, the ability to reuse these meshes in various projects without significant degradation in quality reaffirms their utility and environmental benefits.

However, the trustworthiness and reliability of this product depend on the manufacturing standards adhered to during production. It is crucial for buyers to ensure that their suppliers conform to recognized quality standards and certifications to achieve maximum performance from their wire meshes. Understanding the nuances of production can significantly impact the application outcomes, especially in high-stakes environments such as safety installations or load-bearing components.

In conclusion, electro galvanized welded wire mesh stands out as a product of expertise that brings together durability, functionality, and sustainability. Its versatile applications across industries underline its authority as a go-to material for both practical and creative solutions. Combining this with its low-maintenance nature and environmental benefits makes it a trustworthy choice for companies and individuals vying for efficiency and reliability in their endeavors.