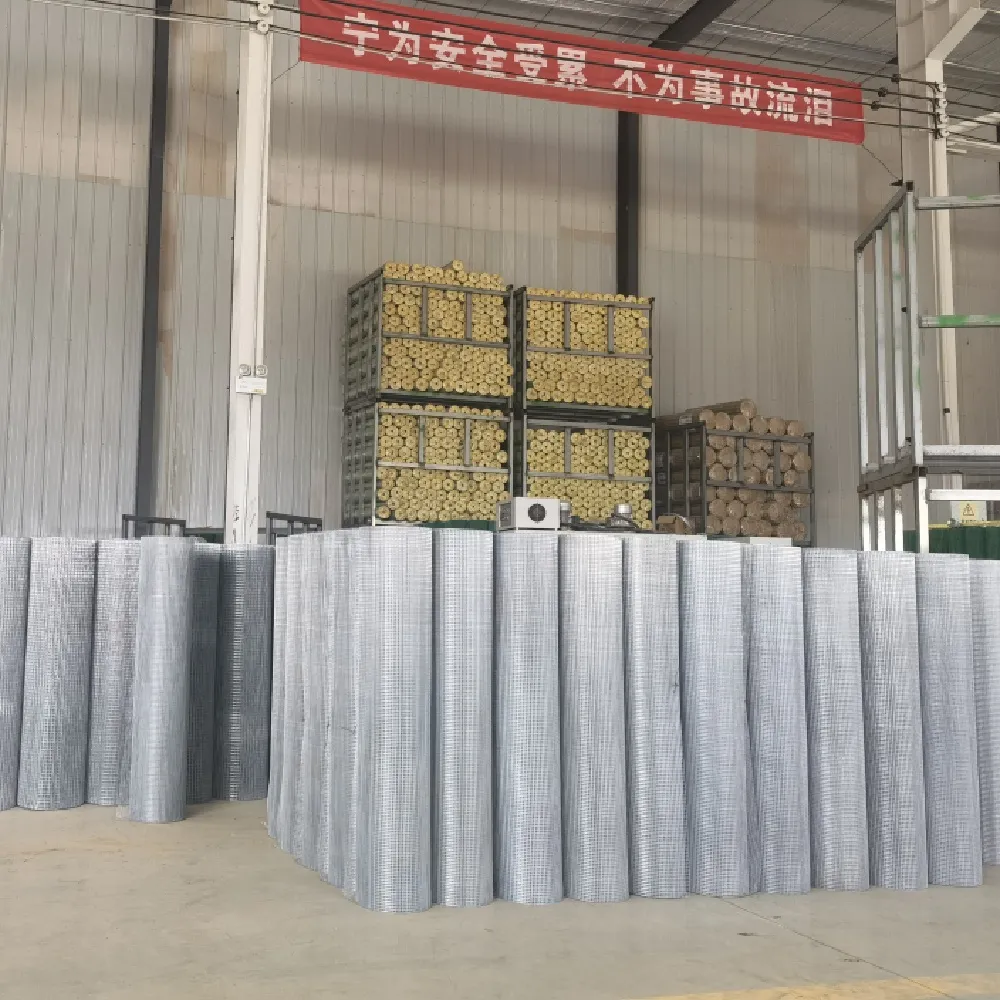

If you’ve spent time around fencing yards or fabrication shops, you’ve surely bumped into Electro Galvanized Welded Wire Mesh. It’s one of those quiet, do-everything materials—security partitions one day, greenhouse benches the next. To be honest, it’s not flashy. But it’s dependable, and that matters more when projects go live and weather happens.

The short version: Electro Galvanized Welded Wire Mesh is low-carbon steel wire welded at intersections, then electroplated with zinc. Many customers say they pick it for its clean surface, consistent openings, and fair price. The zinc layer gives it good anti-corrosion properties and surprisingly strong weather resistance for indoor and light outdoor use. Not forever, of course, but long enough for most commercial cycles.

Typical tests (real-world use may vary): ASTM A641/A641M (zinc coating), ASTM A370 (tensile), AWS D1.3-based weld shear checks, and ASTM B117 salt spray benchmarking. I like to see 72–120 hours neutral salt spray without red rust for this category.

| Item | Typical Spec (≈) |

|---|---|

| Wire Diameter | 0.6–3.0 mm |

| Mesh Opening | 6×6 mm to 50×50 mm |

| Sheet/Roll Size | 1×2 m sheets; 0.9–1.8 m wide rolls |

| Zinc Coating | 8–25 g/m² (electro-galv) |

| Tensile Strength | 340–550 MPa |

| Weld Shear | ≥ 50% of wire tensile (approx.) |

Note: Specs above are typical ranges; custom builds available. Actual performance depends on environment, handling, and coating thickness.

Service life: around 3–8 years inland under moderate exposure; 1–3 years in coastal or acidic environments. If you need more, consider hot-dip galv after welding.

| Vendor | Location / Notes | Lead Time | Coating Uniformity | Docs & Certifications | Price Level |

|---|---|---|---|---|---|

| Tike Metal | East side of Baoheng Rd., Zhaobazhuang Village, Tangfeng Town, Shenzhou, Hengshui, Hebei | 10–18 days | Consistent (±2–3 g/m²) | ISO 9001, MTC, RoHS/REACH on request | Competitive |

| Vendor A | Domestic stockist (mixed origins) | Ready stock/variable | Varies by batch | Basic CoC | Mid |

| Vendor B | Export-focused | 15–25 days | Good, sometimes spotty on edges | ISO claim; partial lot tests | Low |

Comparison based on my notes and customer feedback; always verify current data.

Electro Galvanized Welded Wire Mesh can be tailored: tighter openings for small animal pens, thicker wire for impact zones, or heavier Zn for humid storage rooms. One poultry farm in Malaysia asked for 1.2 mm wire with 12.7×12.7 mm apertures; they reported zero broken welds after six months of daily cleaning. Another project—retail trellis infill in Central Europe—ran 72-hour ASTM B117 tests pre-install; no red rust, only light white zinc bloom. That’s acceptable, honestly.

If your spec calls for elevated corrosion performance, I guess it’s worth upsizing to hot-dip options or adding powder coat topcoat. But for indoor fixtures and guarded equipment, this hits that price-performance sweet spot.

RELATED PRODUCTS