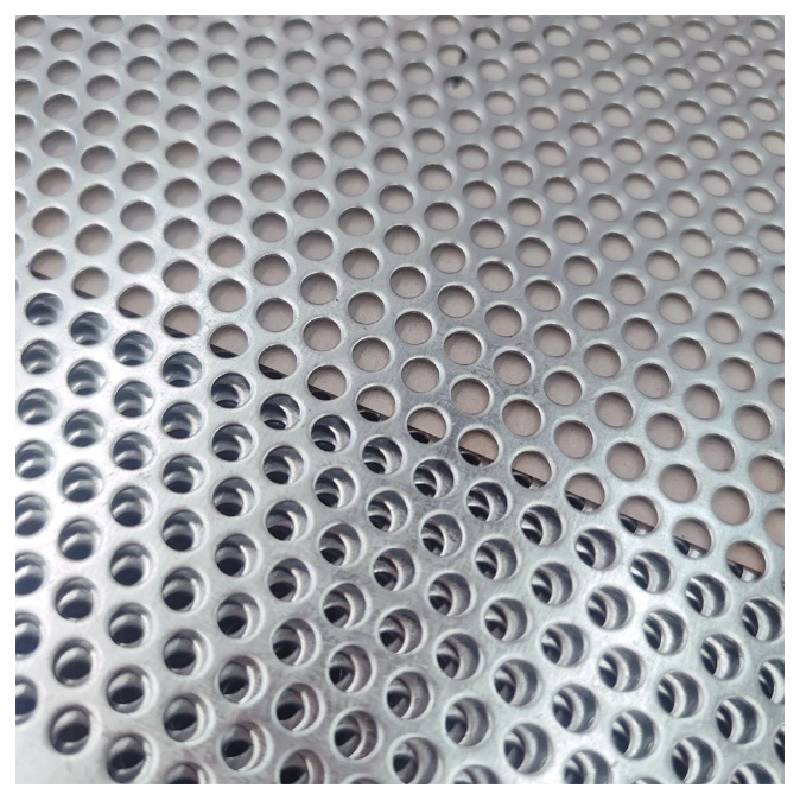

Corrugated metal mesh, an innovative product in the architectural and industrial sectors, has garnered attention for its versatility and durability. This material is a game-changer, offering a blend of strength, aesthetics, and functionality that few can match. A multitude of applications and benefits make corrugated metal mesh an asset in both commercial and residential projects.

In the realm of architecture, corrugated metal mesh is celebrated for its ability to transform facades, interiors, and external cladding. Its unique texture adds depth and dimension to structures, making it an architect’s favorite for creating visually striking exteriors. The mesh can be customized to fit specific design requirements, enhancing its appeal. Architects with a keen eye for detail appreciate its role in creating modern, edgy environments.

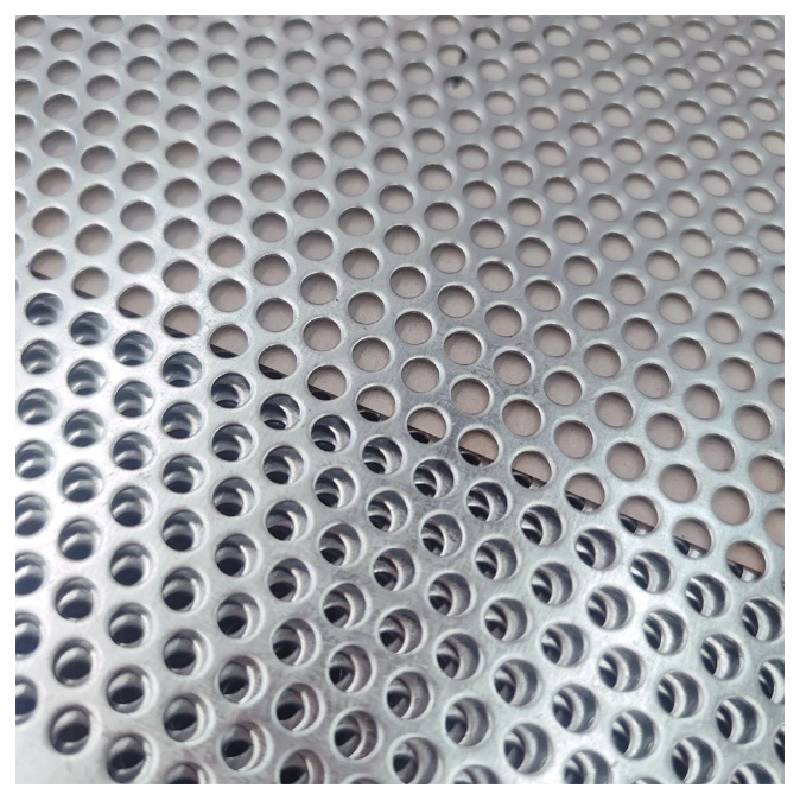

Industrially, corrugated metal mesh serves as a robust solution for safety and wear resistance. Industries dealing with high-impact environments often use this mesh to protect machinery and infrastructure from damage.

Its corrugated design offers enhanced strength, making it an ideal choice for heavy-duty applications. This functionality is a testament to its engineering excellence, crafted to withstand rigorous industrial conditions.

From a construction perspective, the installation ease of corrugated metal mesh is noteworthy. It significantly reduces labor costs and installation times, as its lightweight nature doesn’t require extensive support structures. The mesh is available in various materials like steel, aluminum, and copper, offering flexibility depending on project needs. Its resistance to environmental factors like moisture and extreme temperatures adds to its credibility as a long-term investment.

When it comes to sustainability, corrugated metal mesh stands out as an environmentally friendly option. Metals used in its construction are typically recyclable, aligning with increasing demands for green building practices. This feature makes it particularly attractive for projects seeking LEED certification or adhering to similar standards. The production processes have also evolved to minimize environmental impact, reflecting a commitment to sustainable manufacturing.

corrugated metal mesh

For product manufacturers and suppliers, corrugated metal mesh represents a lucrative market. The demand across architectural and industrial sectors continues to rise, driven by the material's adaptability and numerous benefits. Suppliers are encouraged to maintain high standards of quality and invest in research and development to enhance product offerings. Those who do can establish themselves as leaders in the industry, trusted for delivering excellence.

The expertise behind creating corrugated metal mesh involves meticulous engineering and design principles. Leading manufacturers employ specialists with profound knowledge in material science and architectural design to innovate continually. This expertise ensures that the mesh not only meets but exceeds industry standards, ensuring safety and reliability.

Trustworthiness remains a cornerstone for manufacturers and distributors. Providing transparent information on material specifications, installation guidance, and warranty policies builds customer confidence. Establishing a track record of durability and performance further cements trustworthiness, persuading potential clients of the product’s credibility.

In conclusion, corrugated metal mesh is more than just a building material; it is an embodiment of modern construction principles—strength, aesthetics, and sustainability. Whether enhancing an architectural project or reinforcing industrial safety, its benefits are far-reaching. As advancements continue in this field, its prominence is set to grow, making it a must-have for future-forward construction initiatives. Businesses and consumers alike stand to gain from understanding and utilizing the full potential of corrugated metal mesh.