Galvanized wire, As a widely used metal material, it is highly valued for its superior rust prevention properties and diverse application fields. Galvanizing is a metal treatment process that covers the surface of iron wire with a layer of zinc to improve its corrosion resistance and mechanical properties. This process not only provides visual luster for the wire, but also lays a solid foundation for its application in various harsh environments.

The characteristics of galvanized wire are reflected in its durability and strength

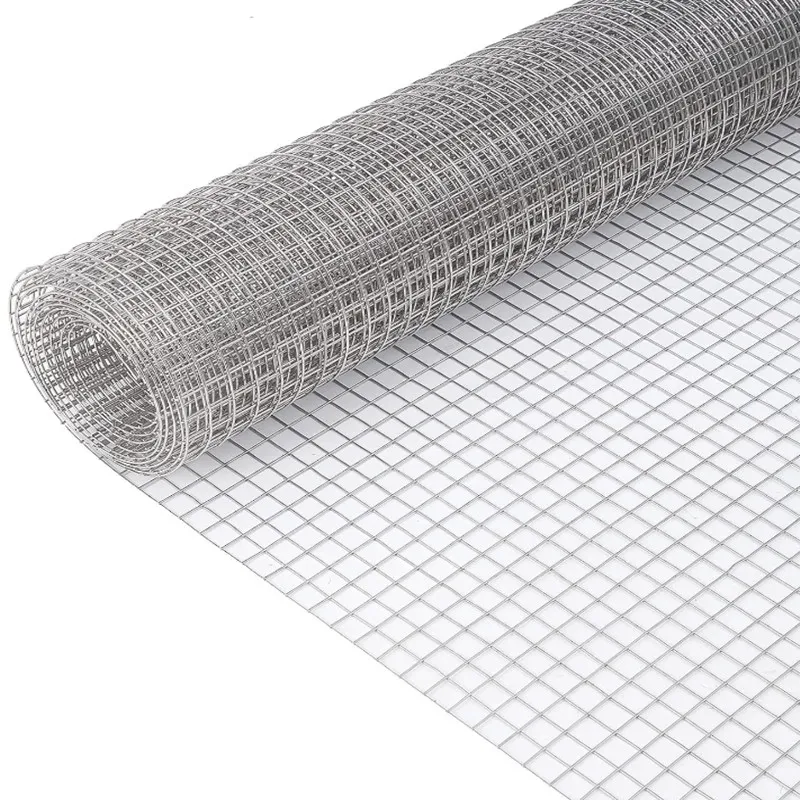

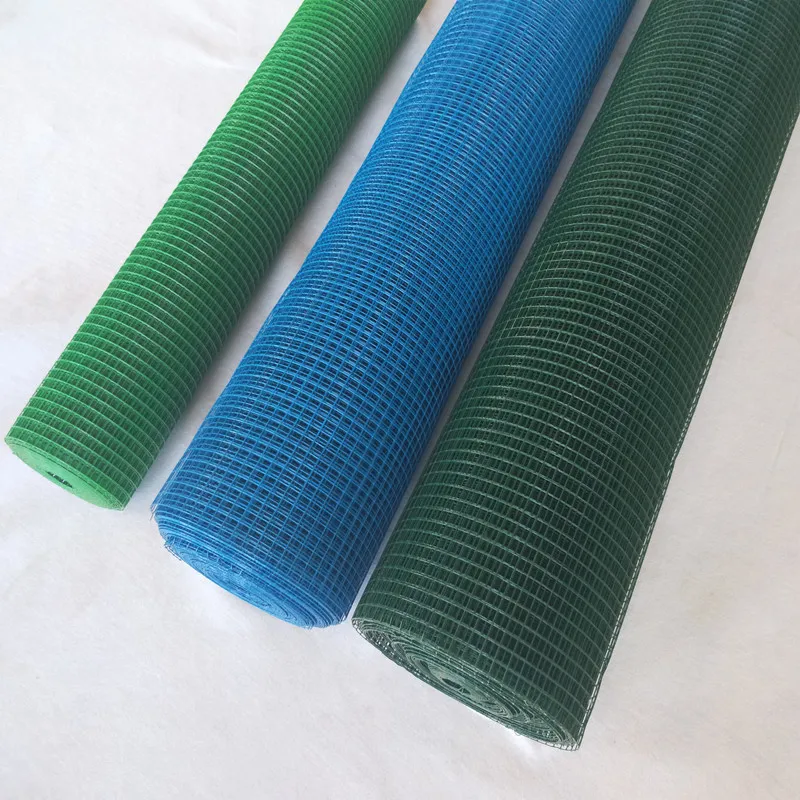

Galvanizing treatment gives iron wire good corrosion resistance in humid or acidic environments. Compared to untreated iron wire, galvanized steel wire has a significantly longer service life and can effectively reduce safety hazards caused by corrosion. This is particularly important for fields such as architecture, agriculture, and horticulture, where galvanized wire is widely used for fences, brackets, grids, and various connecting components.

Galvanized wire has good plasticity and processing characteristics

Due to its mechanical properties not significantly compromised during the galvanizing process, galvanized iron wire can be easily bent and cut to meet various complex construction requirements. In addition, the uniform coverage of the galvanized layer also provides convenience for subsequent welding and connection. Therefore, it is widely used in various fields such as building structures, transportation, machinery manufacturing, and home decoration.

The rust prevention properties of galvanized wire are one of its most significant advantages

Under the protection of the galvanized layer, a hard and dense zinc oxide film is formed on the surface of the iron wire, which can effectively isolate air and moisture and prevent oxidation reactions of the iron wire body. Therefore, even under humid environmental conditions, galvanized steel welded wire can maintain good rust prevention performance. Meanwhile, when the galvanized layer wears out during long-term use, the zinc will continue to oxidize, forming a protective layer of zinc salt, which further enhances its corrosion resistance.

Although galvanized wire has many advantages, attention should still be paid to its applicable environment in practical applications

The galvanized layer may be affected in certain extreme environments, such as high temperatures, strong acids, or strong alkalis, and the corrosion resistance of galvanized steel chicken wire may decrease. Therefore, when selecting materials, the characteristics of the usage environment should be fully considered to ensure that the selected galvanized wire can meet specific needs.

In summary, galvanized wire has been widely used in multiple fields due to its superior rust prevention properties and good mechanical performance. With the development of technology and advances in materials science, the production process and performance of galvanized wire will continue to be improved, providing reliable material support for more industries. In modern industry and daily life, the status of galvanized wire will undoubtedly continue to rise, bringing greater convenience and safety to people.