Navigating the intricate world of industrial materials, catwalk steel grating stands out as a fundamental component in various applications. As industries evolve, the demand for robust and reliable materials like steel grating to ensure safety and efficiency continues to rise. This comprehensive exploration delves into the features, applications, and advantages of catwalk steel grating, while highlighting first-hand experiences and the expertise behind its implementation.

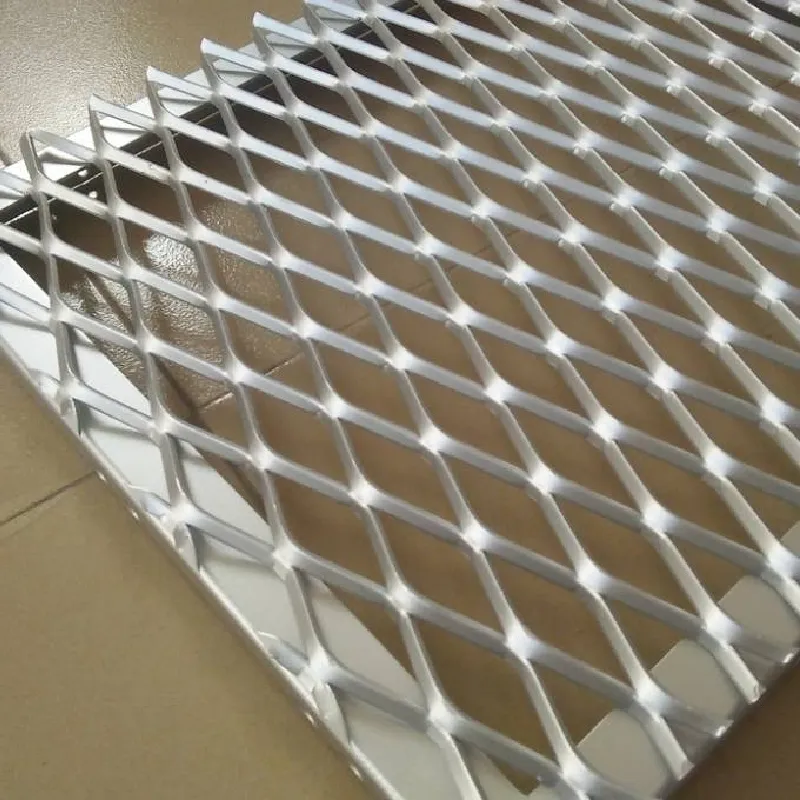

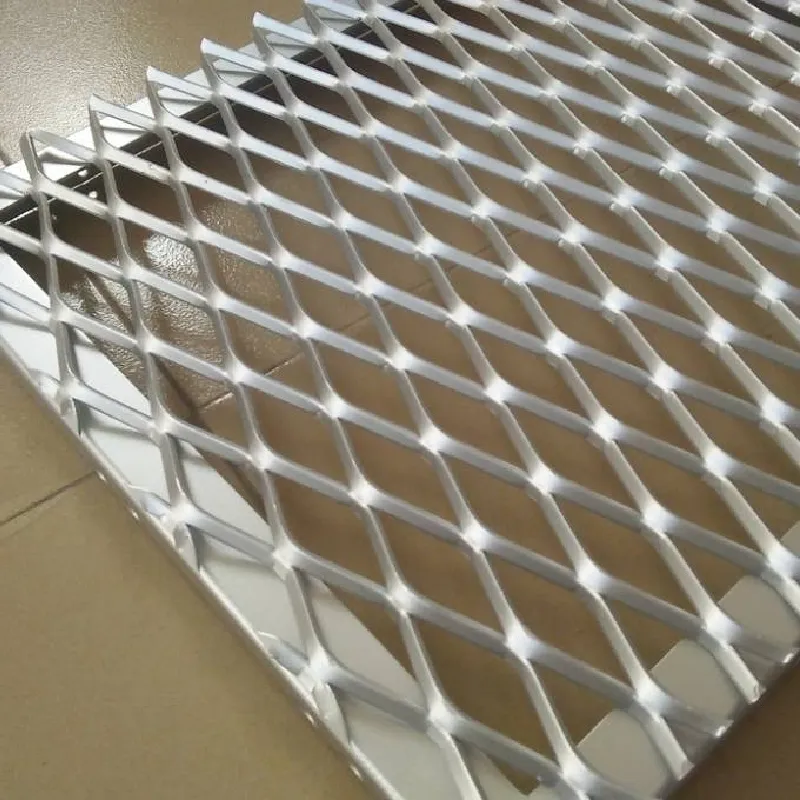

Catwalk steel grating, renowned for its durability and strength, is predominantly used in industrial settings such as factories, shipyards, and power plants. Its ability to support substantial weight and withstand harsh environmental conditions makes it a preferred choice. A core advantage of steel grating lies in its open design, which facilitates efficient drainage and ventilation, reducing the buildup of potentially hazardous materials like water or oil on surfaces. This feature not only preserves the grating’s integrity but also minimizes slippage risks, ensuring a safer environment.

Expertise in manufacturing catwalk steel grating involves understanding its structural composition. Typically constructed from carbon steel, aluminum, or stainless steel, each variant offers unique benefits tailored to specific needs. Carbon steel is favored for its high strength-to-weight ratio and cost-effectiveness, making it ideal for general applications. Meanwhile, stainless steel grating is celebrated for its corrosion resistance, crucial for environments exposed to moisture or chemicals. Aluminum, being lightweight yet durable, serves well in areas where weight constraints are a concern, such as in aerospace or marine applications.

A closer look at real-world usage reveals the grating’s versatility. In petrochemical plants, catwalk steel grating provides safe walkways for staff, enabling seamless inspection and maintenance of complex systems without disrupting operations. In warehouses, its integration facilitates efficient movement of goods, while ensuring adherence to safety standards through its anti-slip properties. A case study involving an oil refinery demonstrates how the implementation of stainless steel grating reduced corrosion-related downtimes by 30%, highlighting its effectiveness and longevity in demanding conditions.

catwalk steel grating

The authoritativeness of catwalk steel grating is further evidenced by compliance with international safety and quality standards. Recognized certifications such as ISO 9001 confirm the grating’s adherence to rigorous manufacturing and quality control processes. This ensures that industries relying on steel grating are equipped with materials that meet stringent safety requirements, reinforcing trust in its deployment across critical sectors.

Trustworthiness is intrinsic to the adoption of catwalk steel grating in mission-critical operations. Companies often rely on established manufacturers that offer comprehensive support, from customized design solutions to installation and maintenance services. This holistic approach significantly reduces the risk of error and enhances operational efficiency. Testimonials from industry leaders underscore the reliability of top-tier steel grating, emphasizing minimal maintenance requirements and exceptional performance under duress.

Moreover, advancements in technology have led to innovative design enhancements in steel grating. Modern approaches include the incorporation of anti-slip coatings and precision-engineered serrated surfaces, further amplifying its safety profile. These innovations result from intensive research and development efforts by manufacturers aiming to elevate product performance while addressing emerging industry challenges, such as heightened safety regulations and sustainability goals.

In conclusion, the deployment of catwalk steel grating extends beyond mere utility; it embodies a commitment to safety, reliability, and adaptability. As industries progress towards more sustainable and efficient operational frameworks, the role of superior materials like steel grating becomes increasingly pivotal. By continuously evolving design and production methodologies, manufacturers are poised to meet future demands while ensuring that catwalk steel grating remains a cornerstone in industrial safety and infrastructural integrity. For professionals in the field seeking a material that offers unparalleled strength, versatility, and peace of mind, catwalk steel grating undoubtedly stands as the preferred choice.