After years walking job sites from Fresno solar farms to pop-up events in LA, I’ve learned the difference between a fence that just looks sturdy and one that survives a windy week, an impatient forklift, and a bored crowd. The market for temporary barriers is shifting—more anti-climb meshes, faster tool-free connections, and yes, greener coatings. That’s where CA Temporary Fence panels from North China’s manufacturing belt (Origin: East side of Baoheng Road, Zhaobazhuang Village, Tangfeng Town, Shenzhou City, Hengshui City, Hebei Province) have been getting attention. To be honest, the price-to-durability balance is the talking point.

Specs always look similar on paper, but the wire, welds, and zinc really separate winners from callbacks.

| Parameter | Typical CA Temporary Fence | Notes |

|---|---|---|

| Panel size | ≈ 6’ H × 8–10’ W (1830 × 2400–3000 mm) | Event sites lean shorter; heavy construction prefers taller |

| Mesh aperture | 60 × 150 mm or 50 × 100 mm | Tighter mesh discourages climbing |

| Wire diameter | 3.0–4.0 mm (Q235) | Real-world use may vary by load/footing |

| Frame tubing | OD 32–40 mm, 1.2–1.6 mm wall | Heavier walls for high-wind zones |

| Finish options | Pre-galv; Hot-dip galv; Powder coat | HDG + powder lasts longest near coasts |

Materials: Q235 low-carbon steel wire and tube. Methods: automatic resistance welding, jig-squared frames, continuous zinc coating. Finishes: pre-galv (economy), hot-dip galvanized to ASTM A123 levels, and optional polyester powder coat for color/brand.

Testing standards in play: salt spray per ASTM B117 (typical lab data: powder over HDG sustains ≈ 480–720 h), coating mass in line with ASTM A123; production under ISO 9001:2015. Weld shear and pull tests sample each lot; visual checks for spatter and burrs (glove-snag test—old foreman trick). Expected service life: ≈ 3–5 years pre-galv, ≈ 5–8 years HDG; coastal winds and handling abuse can shorten that, obviously.

| Factor | Tikemetal CA Temporary Fence | Importer A | Local Rental B |

|---|---|---|---|

| Galv thickness | HDG option, heavy zinc | Light pre-galv | Mixed fleets |

| Weld strength | Lot-tested, consistent | Varies | Used panels; QC varies |

| Certifications | ISO 9001; ASTM references | Limited docs | N/A |

| Lead time | Made-to-order; predictable | Container cycles | Immediate, but limited spec |

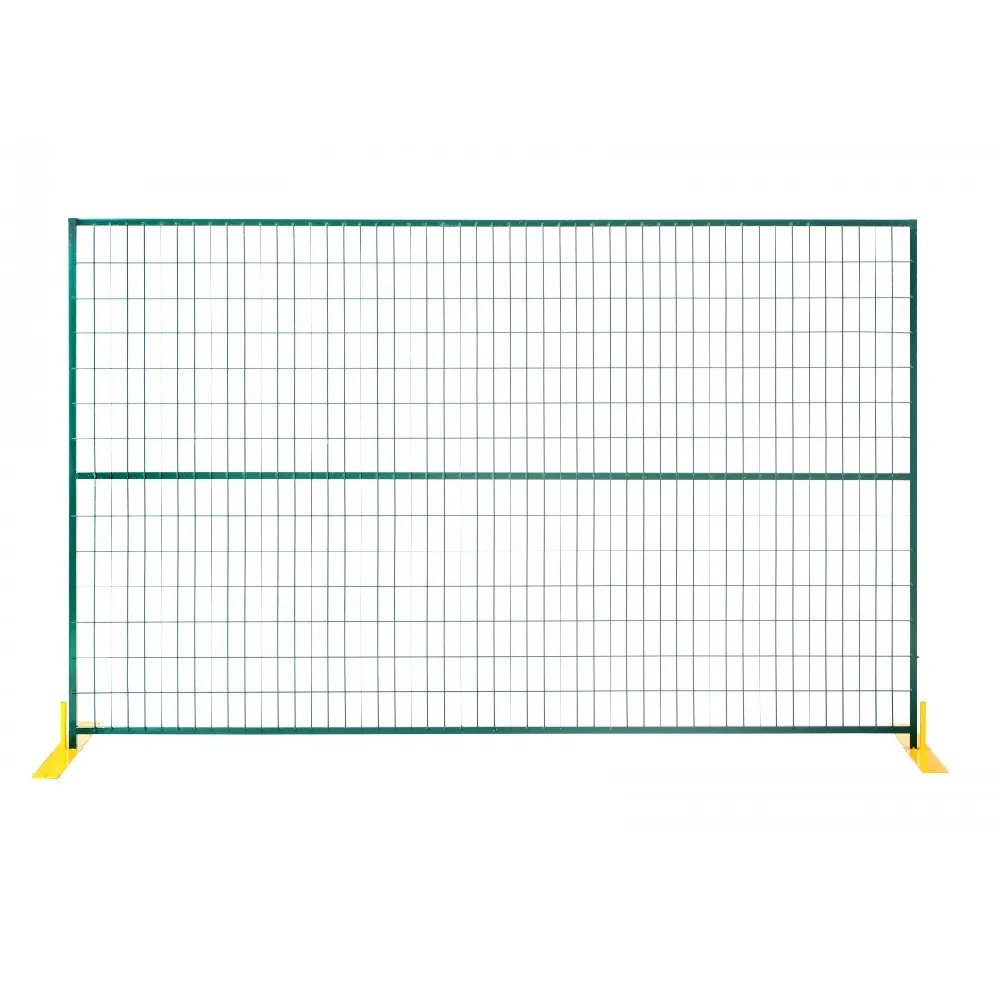

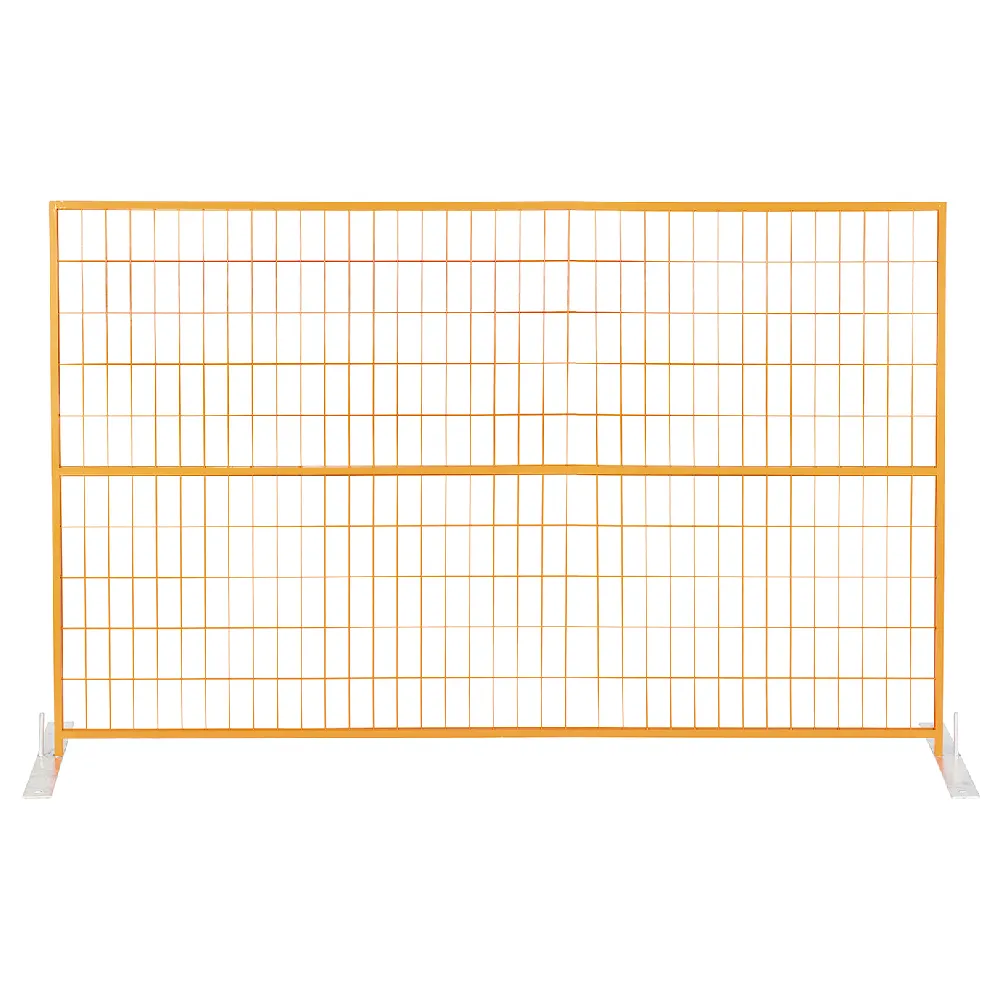

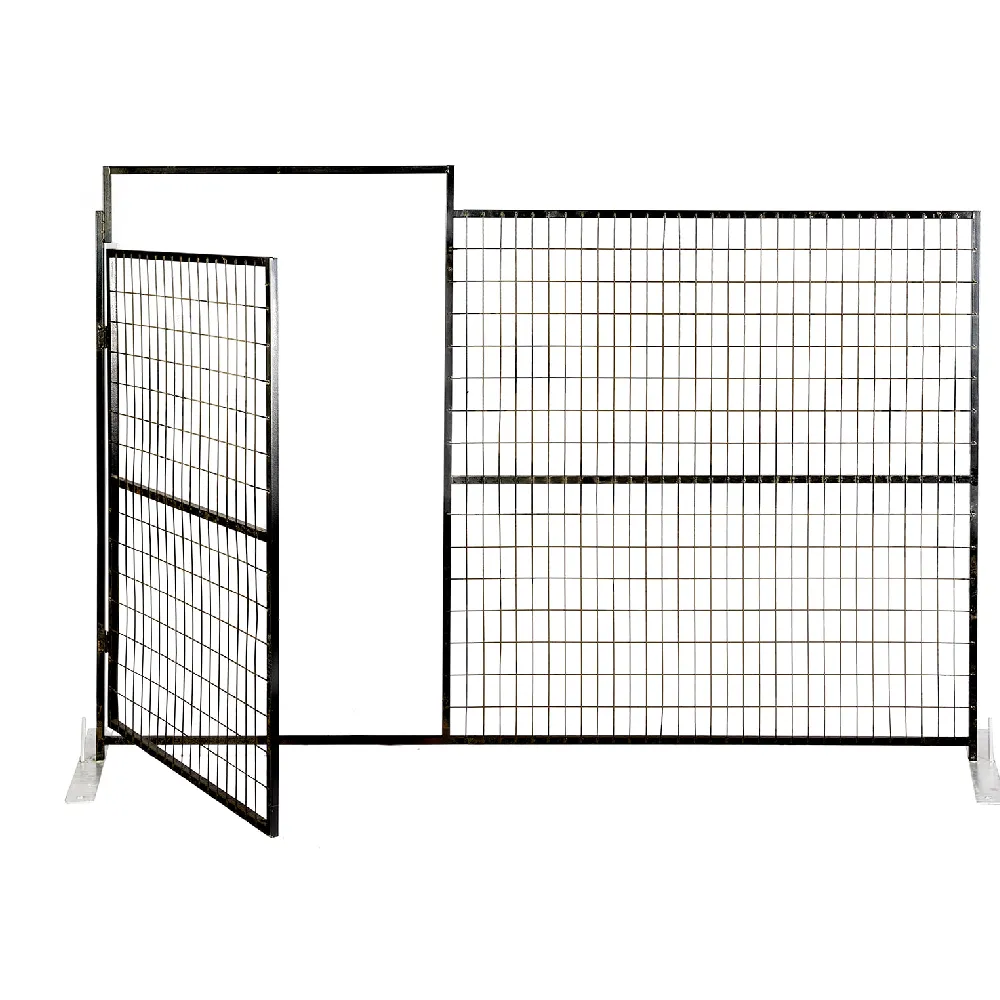

Heights 4’–8’, gates (swing/slide), anti-trip feet, colors (RAL), privacy screens, and branded plates. Many customers say powder-coated orange or yellow helps with public visibility—seems to reduce accidental impacts.

Compliance note: site managers in California often reference Cal/OSHA Construction Safety Orders for barricades and public protection. Height/setback specifics depend on the hazard zone and local AHJ, so check your permit conditions.

RELATED PRODUCTS