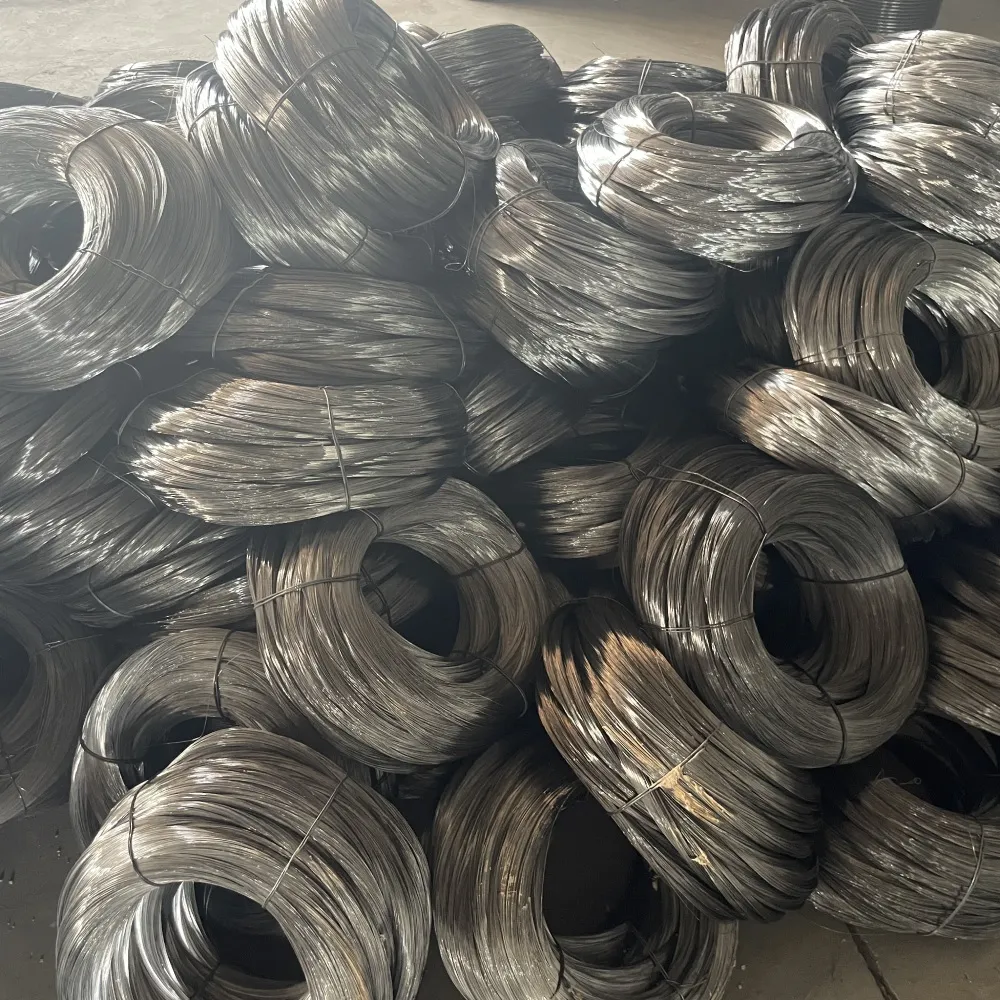

In the intricate web of industrial applications, the humble but mighty black iron wire stands as a testament to material versatility and essential functionality. This fundamental product, derived from high-quality low carbon steel, undergoes a specific annealing process to enhance its ductility and flexibility, making it an ideal choice for a myriad of demanding tasks. Its widespread use spans from robust construction frameworks to intricate crafting projects, underscoring its significant economic and operational value. As a leading iron wire supplier, our commitment is to provide products that not only meet but exceed stringent industry standards, ensuring superior performance and reliability in every application.

The demand for robust and flexible binding solutions continues to grow across various sectors, driving innovation in the manufacturing and application of black annealed iron wire. This material's unique properties, including its excellent tensile strength post-annealing and its resistance to cracking under stress, contribute significantly to its long service life and cost-effectiveness. Understanding the nuances of its production and its broad utility is crucial for businesses seeking optimal material procurement and efficient project execution in today's competitive landscape.

The production of high-quality black iron wire is a precise multi-stage process that transforms raw steel rods into a highly pliable and durable wire. This journey typically begins with the selection of premium low-carbon steel wire rods, known for their inherent strength and malleability. The primary manufacturing process involves cold drawing, where the steel rods are pulled through a series of progressively smaller dies. This process reduces the wire's diameter, increases its tensile strength, and provides the desired gauge. However, cold drawing hardens the wire, making it brittle.

To counteract this hardening and restore ductility, the wire undergoes an annealing process. This involves heating the wire to a specific temperature (typically between 700-900°C) in a controlled atmosphere, often in a bell-type furnace, and then slowly cooling it. This thermal treatment recrystallizes the steel's microstructure, making the wire softer, more flexible, and significantly improving its workability. This crucial step is what differentiates black annealed iron wire from other steel wires, giving it the characteristic black oxide layer and superior pliability. Strict adherence to international standards such as ISO 9001 for quality management and ASTM A853 for general purpose steel wire ensures consistent product quality and performance.

Post-annealing, the wire is inspected for uniform diameter, surface finish, and mechanical properties. Key detection standards often include tests for tensile strength, elongation, and coil integrity. The typical service life of properly manufactured and applied black iron wire can extend for decades, particularly when used in sheltered or non-corrosive environments. In industries like construction, where it's used for rebar tying, or in agriculture for baling, its longevity is critical for structural integrity and operational efficiency. The robust manufacturing process and rigorous quality control measures ensure that the product delivered offers optimal performance and durability.

Understanding the precise technical parameters of black iron wire is paramount for selecting the right product for specific applications. These specifications dictate the wire's suitability for various tasks, influencing factors such as tensile strength, elongation, and overall flexibility. As a reliable iron wire supplier, we ensure that our products meet or exceed the following typical specifications, which are critical for performance and safety.

| Parameter | Typical Range/Value | Measurement Unit | Significance |

|---|---|---|---|

| Wire Diameter (Gauge) | BWG 8 - BWG 22 (4.0mm - 0.7mm) | mm / BWG | Determines strength and flexibility for specific uses. |

| Tensile Strength | 350 - 550 | MPa | Resistance to breaking under tension. |

| Elongation Rate | 15% - 25% | % | Measure of ductility; ability to stretch without breaking. |

| Material | Low Carbon Steel (Q195, Q235) | Ensures optimal annealing properties and strength. | |

| Coil Weight | Typically 10kg - 1000kg | kg | Influences handling and deployment efficiency. |

The black oxide layer on black annealed iron wire not only gives it its characteristic appearance but also provides a mild level of corrosion resistance, particularly against atmospheric oxidation. While it is not as corrosion-resistant as galvanized or PVC-coated wire, its cost-effectiveness and excellent flexibility make it preferred for applications where a non-shiny, easily tieable material is needed. Furthermore, its consistent mechanical properties ensure reliable performance, whether in automated tying machines or manual applications, reducing material waste and improving operational efficiency.

The inherent properties of black iron wire — its impressive flexibility, excellent tensile strength, and cost-effectiveness — position it as a critical component across a diverse range of industries. Its primary use case remains in the construction sector, particularly for securing rebar in concrete structures, where its pliability allows for quick and secure tying, significantly speeding up construction timelines.

Beyond construction, its utility extends to packaging and baling in agriculture for securing hay bales, in recycling centers for bundling waste materials, and in the textile industry. In more specialized heavy industries, such as metallurgy, black iron wire can be used for securing insulation panels on large industrial furnaces or for temporary binding during maintenance work in steel mills. For petrochemical facilities, while not directly in contact with corrosive substances, it's often utilized for general-purpose tying of non-critical components, marking, or temporary structural reinforcement. Its ease of handling contributes to improved worker safety and productivity. The dark finish also allows it to blend seamlessly into many industrial environments without drawing attention, a subtle aesthetic advantage.

The significant advantage of using black annealed iron wire lies in its optimal balance of workability and strength. Unlike harder, unannealed wires, it can be easily bent, twisted, and tied without fracturing, which minimizes labor time and material waste. This translates directly into cost savings and enhanced project efficiency. Furthermore, its consistent quality reduces the likelihood of failures, contributing to the overall integrity and longevity of projects where it is employed. This focus on reliability and performance makes it a preferred choice for professionals seeking dependable materials.

When sourcing black iron wire, selecting the right iron wire supplier is as crucial as the product itself. The market offers a range of manufacturers, each with varying capabilities, quality controls, and pricing structures. A detailed comparison can help decision-makers identify a partner that aligns with their specific project requirements and budgetary constraints. Key factors to consider include manufacturing capacity, quality certifications, customization options, and after-sales support.

| Feature | Typical Supplier A (Commodity) | Typical Supplier B (Specialized/Tikemetal) |

|---|---|---|

| Quality Certifications | Basic ISO 9001 (sometimes) | ISO 9001, ASTM, SGS/BV inspection reports |

| Customization Options | Limited (standard gauges/coils only) | Extensive (custom gauges, coil weights, packaging) |

| Delivery Lead Time | Variable, often longer for specific orders | Streamlined, reliable, often shorter for custom orders |

| Technical Support | Minimal, basic product info | Comprehensive, application-specific guidance |

| Pricing Model | Often lowest base price, hidden costs | Competitive, transparent black annealed iron wire quotes |

A key differentiator is the ability to provide tailored solutions. While generic suppliers may offer standard dimensions, a specialized iron wire supplier can provide custom gauges, coil weights, and even specific packaging to optimize your operational workflow. For instance, a construction project might require specific coil sizes for automated rebar tying machines, or an agricultural client might need particular baling wire lengths. Requesting detailed black annealed iron wire quotes that include lead times, packaging options, and quality assurance specifics is vital for a comprehensive evaluation.

Our reputation as a trusted iron wire supplier is built on a foundation of consistent quality and customer-centric service. With over a decade of experience in the metal industry, we have cultivated partnerships with leading construction firms and industrial distributors globally. Our commitment to meeting diverse needs is reflected in our robust production capabilities and a dedicated technical support team ready to assist with any application challenge, ensuring that every project benefits from the highest quality black iron wire.

The practical effectiveness of black iron wire is best illustrated through its successful deployment in various demanding environments. One notable case involved a large-scale infrastructure project in Southeast Asia, where over 500 tons of our premium black annealed iron wire were supplied for rebar tying in a complex highway overpass system. The project managers reported significant time savings due to the wire's consistent pliability and strength, leading to faster rebar cage assembly and reduced labor costs.

Another success story comes from a major agricultural cooperative in North America. They utilized our custom-sized coils of black iron wire for their high-volume hay baling operations. The wire’s uniform tensile strength and excellent knotting capability drastically minimized machine downtime caused by wire breakages, leading to a 15% increase in daily baling output during peak season. Customer feedback consistently highlights the wire's reliability and the responsive support from our team, which proved invaluable in optimizing their processes.

These instances underscore our commitment not just to manufacturing a product, but to providing solutions that drive efficiency and profitability for our clients. Our long-standing relationships with clients are built on trust, transparency, and the proven performance of our products, ensuring that when businesses request black annealed iron wire quotes, they receive not just a price, but a comprehensive partnership offer. We pride ourselves on understanding specific client needs and delivering tailored solutions that consistently exceed expectations.

Black annealed iron wire undergoes a heat treatment process (annealing) to achieve superior flexibility and ductility, making it very easy to bend and tie without breaking. Its characteristic black color comes from the iron oxide layer formed during annealing. Galvanized wire, conversely, is typically unannealed (harder) and coated with a layer of zinc to provide enhanced corrosion resistance. While galvanized wire is preferred for outdoor applications exposed to harsh weather, black annealed wire is chosen for its workability and cost-effectiveness in less corrosive or interior environments, such as rebar tying.

Absolutely. As a dedicated iron wire supplier, we specialize in providing tailored solutions. We offer extensive customization options for black iron wire, including a wide range of gauges (from fine to heavy duty), various coil weights (e.g., small rolls for manual use, large coils for automated machines), and custom packaging solutions. Our team works closely with clients to understand their precise requirements and deliver products that integrate seamlessly into their operations. We encourage clients to discuss their specific needs when requesting black annealed iron wire quotes.

Our standard delivery lead time for common specifications of black iron wire is typically 10-15 business days, depending on order volume and destination. For custom orders, lead times will be provided with your specific black annealed iron wire quotes, taking into account production complexity. We stand by the quality of our products with a comprehensive warranty against manufacturing defects. Details of our warranty and quality assurance policies are transparently provided with every quotation, reinforcing our commitment to customer trust and product reliability.

In conclusion, the enduring relevance of black iron wire across diverse industrial applications is a testament to its unique blend of flexibility, strength, and cost-effectiveness. From fundamental construction projects to specialized industrial uses, its reliable performance is consistently proven. Choosing a knowledgeable and experienced iron wire supplier who understands the nuances of manufacturing, adheres to stringent quality standards, and offers customized solutions is critical for optimizing your operations and ensuring project success.

Our dedication to delivering superior quality black annealed iron wire, coupled with our commitment to exceptional customer service and technical support, positions us as an ideal partner for your procurement needs. We invite you to explore our product offerings and contact us for detailed black annealed iron wire quotes tailored to your specific project requirements, ensuring you receive a product that truly adds value.

RELATED PRODUCTS