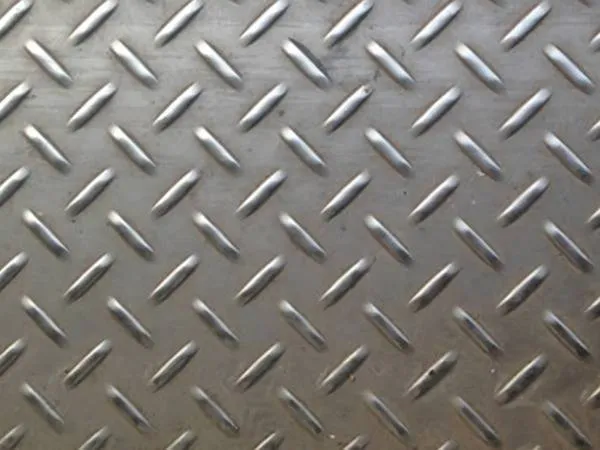

Aluminum checkered sheets, often known as tread plates or durbar floor plates, have become a cornerstone in numerous industries due to their outstanding durability, versatility, and aesthetic appeal. With their embossed patterns and lightweight structure, these sheets are not only functionally superior but also visually appealing. To understand their pivotal role across various sectors, let's explore some of the key elements of these versatile metal sheets.

One of the standout features of aluminum checkered sheets is their excellent anti-slip characteristics, thanks to the raised diamonds, bars, or other patterns on their surface. This makes them an ideal choice for flooring applications in industrial settings where safety is a paramount concern. Their non-slip surface significantly minimizes the risk of accidents in high-traffic areas like ramps, staircases, and transport vehicles. Through firsthand user experiences in the construction and automotive industries, these sheets have been consistently praised for enhancing workplace safety.

From a professional standpoint, aluminum checkered sheets possess a perfect blend of strength and lightweight properties. This combination makes them an excellent material for fabricating products requiring both durability and reduced weight, such as trailers, truck beds, and marine applications. Experts in material science acknowledge that aluminum’s intrinsic ability to resist corrosion further adds to the longevity and low-maintenance nature of checkered sheets, making them a first-choice material in environments exposed to moisture and various chemicals.

In the realm of design and aesthetics, aluminum checkered sheets provide a unique industrial look that appeals to modern architectural styles. They're frequently used in decorative elements, including furniture, wall panels, and even luxury interior finishes. Architects and interior designers cite the metal’s reflective surface and texture as elements that introduce an engaging visual dynamic to spaces, achieving a balance between functionality and style.

The production of aluminum checkered sheets is underpinned by cutting-edge technology and rigorous quality controls. Leading manufacturers apply advanced embossing techniques to ensure the raised patterns maintain consistent height and thickness across the entire sheet. This uniformity is crucial for applications where precise pattern specifications are required. Authoritative bodies in metal fabrication guarantee that industry standards are rigorously followed during production, thereby assuring clients of the sheets’ reliability and performance.

aluminum checkered sheet

Trust in aluminum checkered sheets extends beyond the product itself to the companies that manufacture them. Many producers adhere to sustainable practices, utilizing recycled aluminum to minimize environmental impact. The eco-friendly production process not only reduces carbon footprint but also caters to an increasing societal demand for sustainable building materials. Engaging with manufacturers who prioritize environmental responsibility provides an added layer of trustworthiness, appealing to eco-conscious consumers and companies alike.

Moreover, maintenance and upkeep of aluminum checkered sheets are remarkably straightforward. A simple cleaning routine involving mild detergents and water is typically sufficient to keep the sheets in pristine condition. Compared to other materials like steel, aluminum does not rust, which eliminates the need for regular maintenance and treatments to prevent corrosion. This ease of upkeep saves both time and costs, particularly important for large-scale installations or high-maintenance environments.

The adaptability of aluminum checkered sheets cannot be overstated. They are easily cut, welded, and formed into desired shapes, accommodating specific project requirements across different industries.

This feature is particularly beneficial in custom production scenarios where detailed specifications must be met. For businesses seeking material solutions that provide flexibility without compromising on integrity, aluminum checkered sheets represent an optimal choice.

In conclusion, aluminum checkered sheets continue to prove their indispensable use across various industries, from construction and transportation to interior design. Their ability to meet stringent safety requirements, plus their durability and aesthetic flexibility, make them a remarkable product. Coupled with the backing of industry-leading production standards and sustainable practices, these sheets stand as a benchmark for quality and reliability, reinforcing their status as a trusted material of choice for professionals worldwide.