Iron binding wire is a versatile and essential material used in various industries, especially in construction and agriculture. It is primarily used to secure steel rods and mesh in concrete reinforcement, making it a crucial element in the construction of buildings, roads, bridges, and other infrastructure projects. The flexibility and strength of iron binding wire make it ideal for ensuring that metal reinforcement stays securely in place. Its availability in different gauges also makes it suitable for a wide range of applications, from small-scale projects to large industrial uses. The iron binding wire is easy to use, cost-effective, and provides excellent tensile strength, which is critical for maintaining the integrity of reinforced concrete structures. Whether you're a contractor or a DIY enthusiast, iron binding wire is the go-to solution for securing materials in construction projects.

Gauge Galvanized Wire: The Durable and Corrosion-Resistant Option

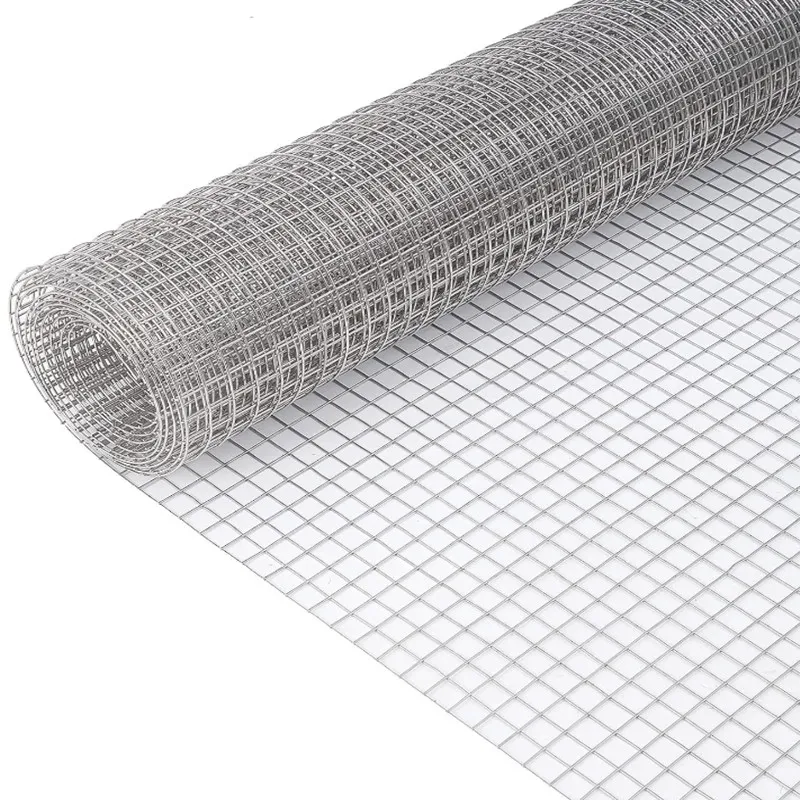

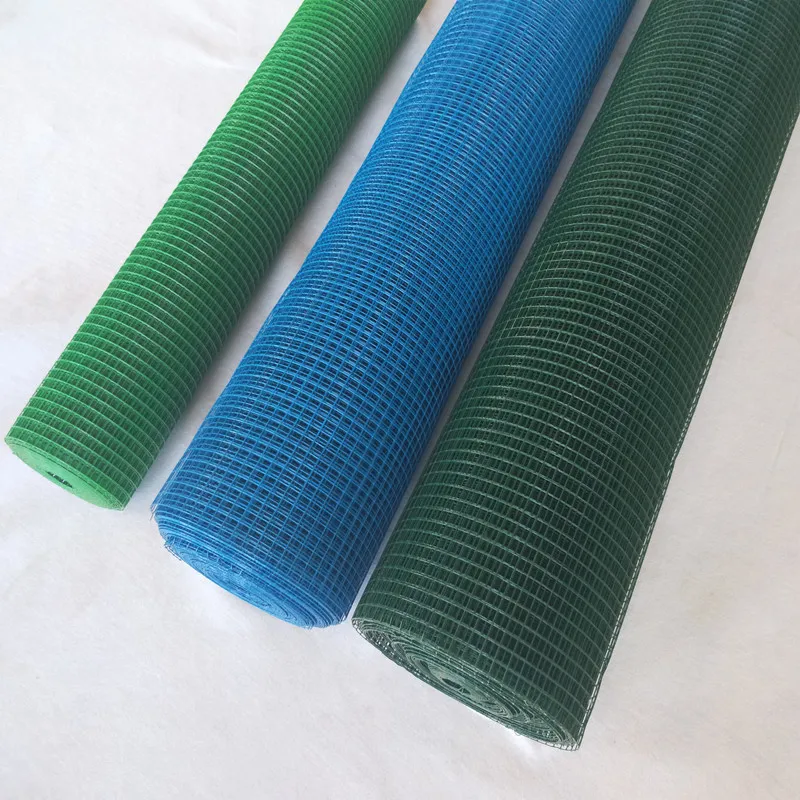

When selecting wire for industrial use, the gauge galvanized wire is one of the most popular choices due to its durability and corrosion resistance. This wire is coated with a layer of zinc, which protects it from rust and corrosion, making it ideal for outdoor and high-moisture environments. The gauge galvanized wire is commonly used for fencing, construction, and agricultural purposes because it can withstand harsh weather conditions without losing its strength. It’s also used in various industries, including telecommunications, electrical work, and manufacturing, due to its versatility and long-lasting nature. The gauge galvanized wire can be found in different thicknesses, allowing for customized applications depending on the specific project requirements. For those looking for a wire solution that offers both reliability and strength, gauge galvanized wire is an excellent option.

Iron Binding Wire Price: Cost-Effective Solutions for Your Projects

When considering materials for a construction or industrial project, the iron binding wire price is an essential factor. Fortunately, iron binding wire is an affordable option that provides significant value for money. The cost of iron binding wire varies depending on factors such as the thickness, quantity, and supplier, but it is generally a cost-effective choice compared to other binding or reinforcement methods. This makes iron binding wire an attractive option for large-scale projects that require substantial quantities of material, such as construction, manufacturing, and agriculture. Despite its low cost, iron binding wire doesn’t compromise on quality, offering the strength and flexibility needed to secure metal reinforcement in concrete and other structures. Whether you are working on a small or large project, iron binding wire price remains competitive, ensuring you get excellent value while maintaining safety and durability.

Iron Wire Manufacturer: Choosing the Right Supplier for Quality Materials

When sourcing iron wire, finding a reliable iron wire manufacturer is crucial for ensuring you receive high-quality materials. A reputable iron wire manufacturer will offer a range of products, including iron binding wire, galvanized wire, and other specialized wire types to meet the specific needs of your projects. Quality should be the top priority when selecting an iron wire manufacturer because poorly made wire can compromise the safety and durability of your construction or industrial applications. A trusted manufacturer will produce iron binding wire with consistent thickness and strength, ensuring that the wire performs optimally under pressure. By choosing the right iron wire manufacturer, you ensure that you receive top-grade materials that meet industry standards and provide lasting performance for your projects.

Iron Binding Wire FAQs

What is the primary use of iron binding wire?

Iron binding wire is primarily used for securing steel rods and mesh in construction, particularly in concrete reinforcement. It ensures that the metal reinforcement stays securely in place, providing stability to the structure.

How does gauge galvanized wire differ from regular wire?

Gauge galvanized wire is coated with zinc to prevent corrosion, making it more durable and resistant to rust. Unlike regular wire, which may degrade over time, gauge galvanized wire maintains its strength and longevity even in harsh environments.

What factors affect the price of iron binding wire?

The iron binding wire price depends on various factors, including wire thickness, quantity, quality, and the supplier. Bulk purchases often lead to discounted rates, and the price may vary based on regional market trends.

Why should I choose an iron wire manufacturer with a good reputation?

Choosing a reputable iron wire manufacturer ensures that the wire is produced to high-quality standards, offering consistency in thickness and strength. A reliable manufacturer will provide durable products that perform well in construction and industrial applications.

Can I use iron binding wire for other purposes besides construction?

Yes, iron binding wire can be used for various purposes beyond construction, such as in agriculture for tying plants or for general industrial uses, including fencing and wire mesh applications.