Navigating the world of construction and industrial applications reveals a myriad of materials each tailored for specific purposes. Among these, 316 stainless steel welded wire mesh stands out as a premium option, renowned for its robustness, versatility, and resilience.

316 stainless steel welded wire mesh is primarily composed of molybdenum-bearing steel, giving it exceptional corrosion resistance, especially in chloride environments such as those found in marine and chemical applications. This innate resistance to corrosion makes it ideal for industries where durability against environmental stressors is paramount.

When it comes to real-world applications, this type of mesh is a staple in industries ranging from petrochemical to pharmaceuticals. In the realm of architecture, 316 stainless steel welded wire mesh serves not only a functional role but also an aesthetic one. Its sleek, modern appearance enhances interior designs, providing a contemporary look while ensuring structural reinforcement.

In highly corrosive environments, such as coastal regions or chemical plants, choosing 316 stainless steel welded wire mesh is not merely an option but a necessity. Its unmatched resistance to pitting and crevice corrosion ensures longevity and reliability, reducing the need for frequent replacements or repairs. This longevity translates to cost savings over time, reinforcing its value proposition.

316 stainless steel welded wire mesh also exhibits superior tensile strength and durability, which are crucial in industries where mechanical stress and pressure are daily challenges. This strength does not come at the expense of flexibility; it retains a degree of malleability that allows it to be shaped and customized according to specific project needs. This adaptability makes it a preferred choice for bespoke applications where standard materials fall short.

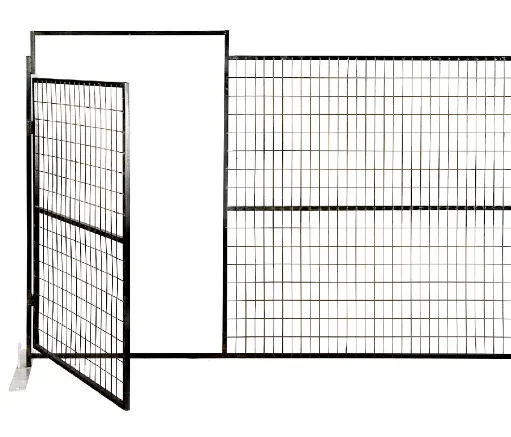

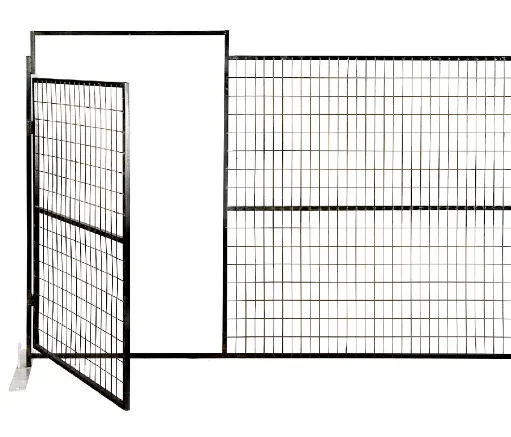

316 stainless steel welded wire mesh

From an expertise perspective, working with 316 stainless steel requires a nuanced understanding of its properties and capabilities. Professionals in the field vouch for its weldability, noting that it can be constructed and manipulated with precision to meet stringent industry standards. Its ability to form a strong and secure joint without losing its corrosion-resistant properties is a testament to its superior manufacturing processes.

Trustworthiness and reliability are equally significant. Companies that specialize in providing 316 stainless steel welded wire mesh are often those with a track record of quality assurance and an in-depth understanding of their product line. They prioritize adhering to international standards, ensuring that each mesh unit delivered holds up to the rigors of real-world applications.

For those seeking an authoritative perspective on material choice, consulting with experts who have decades of experience in metallurgy and industrial design is invaluable. These experts offer insights that go beyond the technical specifications, delving into practical advice and strategic recommendations for selecting materials that meet specific application needs.

Ultimately, the deployment of 316 stainless steel welded wire mesh in a project is not merely a decision based on specifications; it reflects a commitment to quality, performance, and longevity. Its exceptional characteristics make it a go-to resource for those aiming to excel in environments where lesser materials might falter. To truly appreciate its value, one must consider the lifetime performance and the peace of mind that comes with knowing you've chosen a material that stands up to the most demanding conditions.