Whether you're delving into an industrial application or a high-end residential project, the choice of materials can significantly impact the outcome's longevity and performance. The 316 stainless steel mesh screen is a product that seamlessly merges durability with versatility, making it a frontrunner in multiple applications.

316 stainless steel, a variant of the famous 304 stainless steel, contains molybdenum, which enhances its corrosion resistance capabilities beyond those of its predecessor. This becomes incredibly advantageous in environments subject to salt, such as coastal regions or industries dealing with chemicals. The mesh screen's robust resistance to chlorides and an array of chemicals makes it ideal for use in marine environments where frequent exposure to seawater can be an issue.

One practical experience that highlights the superiority of 316 stainless steel mesh screens is in water filtration systems. A filtration company, renowned for its commitment to quality, switched to using 316 meshes for its filters installed in brackish and seawater desalination plants. Over time, they documented a marked decrease in corrosion-related issues, subsequently reducing maintenance costs and increasing the lifespan of these systems.

This example showcases not just personal testimonials but also the empirical support for the mesh screen's effectiveness.

From an engineering standpoint, the 316 stainless steel mesh screen exemplifies what professionals in the field seek impeccable craftsmanship with uncompromised performance. The mesh is woven with precision, often available in varying sizes, thus adapting to different industrial needs. Its application is widespread across sectors including food processing, pharmaceuticals, and petrochemicals where contamination and durability are of utmost concern. For example, in food processing, where hygiene and contamination prevention are non-negotiable, 316 meshes serve as a formidable option due to their ease of cleaning and resistance to acidic or alkaline substances that may arise in food items.

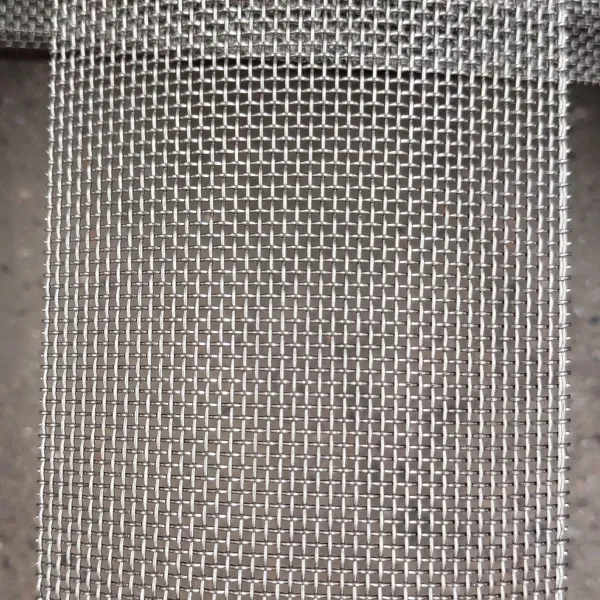

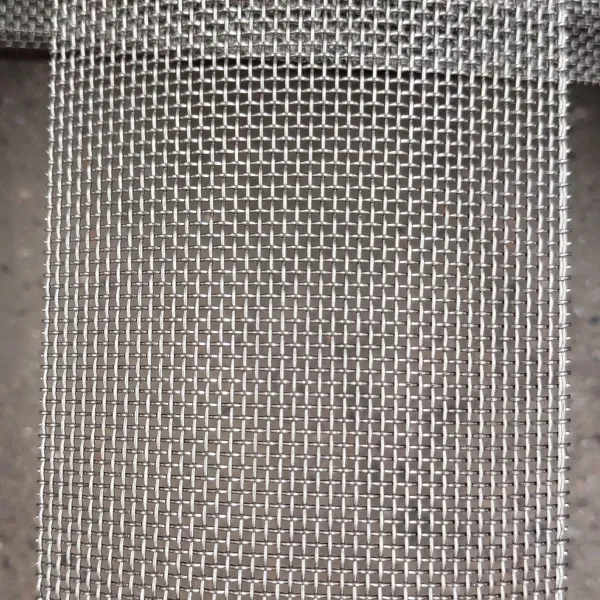

316 stainless steel mesh screen

The expertise embedded within the production of 316 stainless steel mesh screens cannot be overstated. These screens are manufactured under stringent quality checks, ensuring that each product meets industry standards. Such diligence in production process establishes a benchmark that other materials often find challenging to match. Engineers and industrial designers vouch for this material based on trusted expertise and the assurance that it meets regulatory standards for safety and reliability.

An important facet of any industry is the trustworthiness of its materials. Over time, 316 stainless steel has earned its spot as a trustworthy option thanks to consistent and reliable performance across various uses. In the construction of storage tanks, pipes, and other installations where failure is not an option, specifying 316 mesh ensures integrity. Customers and businesses rest easier knowing the material conforms to a remarkable standard of safety and efficiency.

As industries face the ongoing challenge of seeking sustainable and long-lasting solutions, the role of authoritative and credible materials such as the 316 stainless steel mesh screen becomes increasingly important. The demand is not just for any material but for those that display superior properties validated through expert review and real-world application. The comprehensive advantages of 316 stainless steel mesh screens make them an unparalleled choice for applications demanding durability coupled with high performance, backed by years of proven reliability and professional recommendation.