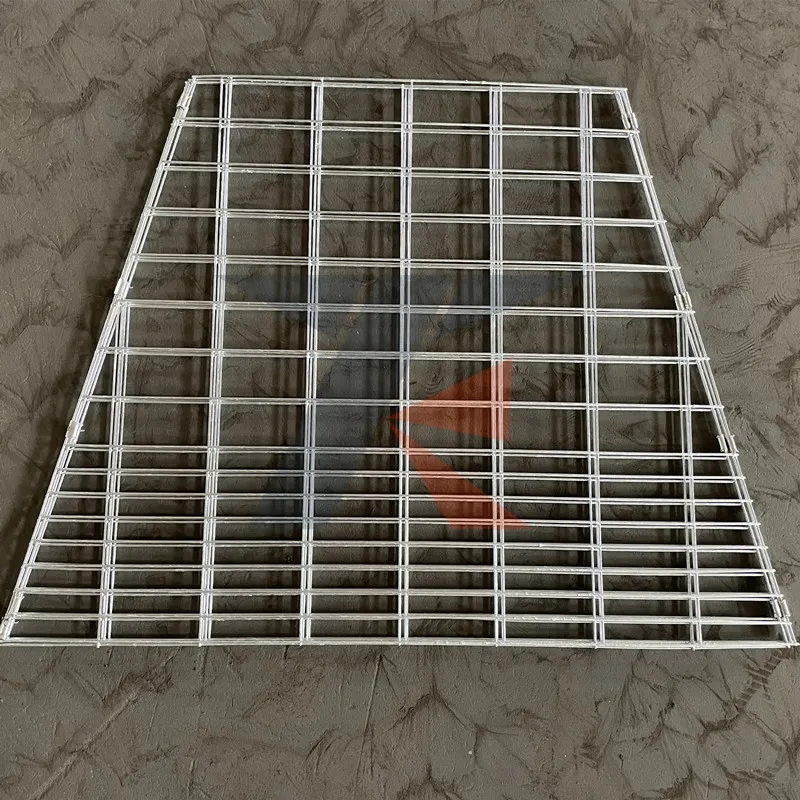

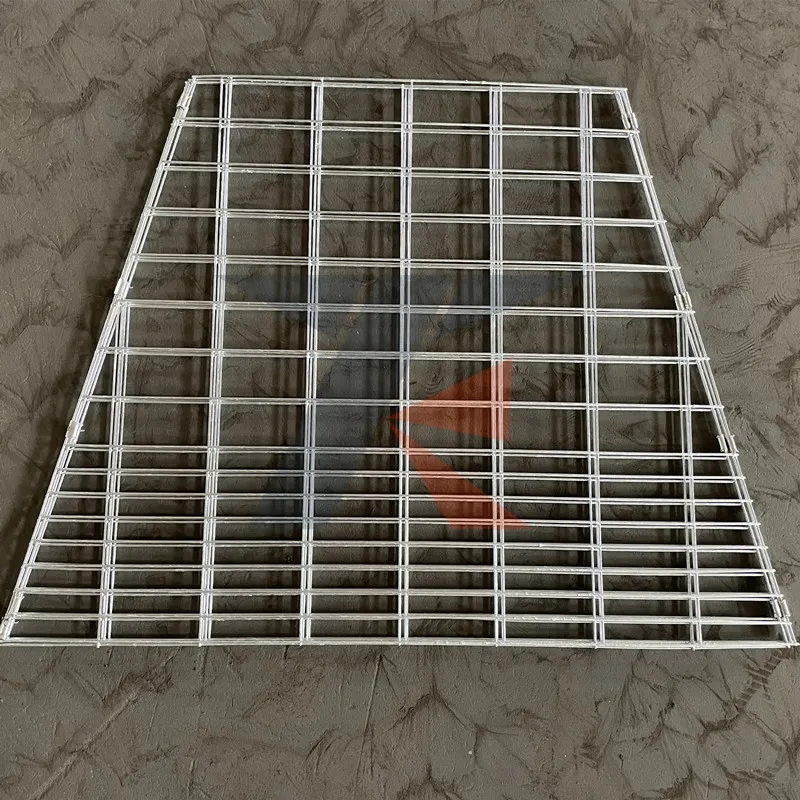

316 stainless steel grating is a critical component in industrial applications, notable for its superior resistance to corrosion, making it ideal for harsh environments. With years of experience in the metal industry, I have seen how 316 stainless steel grating can transform both industrial and architectural projects. From a professional standpoint, its unique blend of durability, strength, and reliability sets a high standard for construction materials.

316 stainless steel is an austenitic alloy that includes molybdenum, enhancing its resistance to chloride corrosion and acidic environments. This makes it particularly useful in marine, chemical, and wastewater treatment industries. The durability of 316 stainless steel grating stems from its ability to withstand extreme temperatures and corrosive elements, which is crucial when the grating is used in walkways, platforms, and drainage covers.

As an industry expert,

I can attest to its versatility. Not only does 316 stainless steel grating offer functional advantages, but it also provides aesthetic appeal for architectural applications. Its sleek appearance is often incorporated in modern building designs, offering a clean, contemporary look. The ease with which it can be fabricated into different sizes and shapes gives architects and engineers the flexibility needed to meet various project specifications.

In terms of authoritative standing, 316 stainless steel gratings comply with international standards, making them a trusted choice for engineers and construction leaders worldwide. Standards such as ASTM A240/A240M ensure the material meets rigorous quality and performance specifications. This compliance guarantees that the gratings will perform effectively over an extended period, even in demanding environments.

316 stainless steel grating

Trustworthiness in construction materials is non-negotiable, and 316 stainless steel grating delivers on this front splendidly. Its maintenance is relatively low compared to other materials, owing to its natural resistance to rust and staining. This not only prolongs the lifespan of the installation but also reduces long-term costs, a significant factor for project managers and financial planners.

An anecdotal observation from a recent project involved the installation of 316 stainless steel grating in a coastal facility. Despite the aggressive saline environment, the grating showed no signs of degradation after several years of service, a testament to its unmatched corrosion resistance. The client reported significant savings in maintenance and replacement costs, further solidifying their trust in the material's efficacy.

For those considering using 316 stainless steel grating, it is imperative to source from reliable suppliers who provide quality assurances. The metallurgical integrity of the grating plays a crucial role in its performance; therefore, verifying certification and compliance with standards is essential.

In conclusion, the application of 316 stainless steel grating is expansive and backed by a wealth of expertise and evidence supporting its efficiency. It stands out as a paramount choice for sectors requiring robust, long-lasting, and aesthetically pleasing solutions. As industries continue to evolve, the role of such high-grade materials will undoubtedly become more prominent, reinforcing the foundation upon which modern industrial and architectural designs are built.