- Galvanized Metal Mesh Fundamentals and Technical Advantages

- Performance Data Comparison Across Manufacturers

- Customization Options for Specialized Applications

- Real-World Implementation Case Studies

- Installation Best Practices

- Maintenance Protocols for Longevity

- Future Outlook and Material Innovation

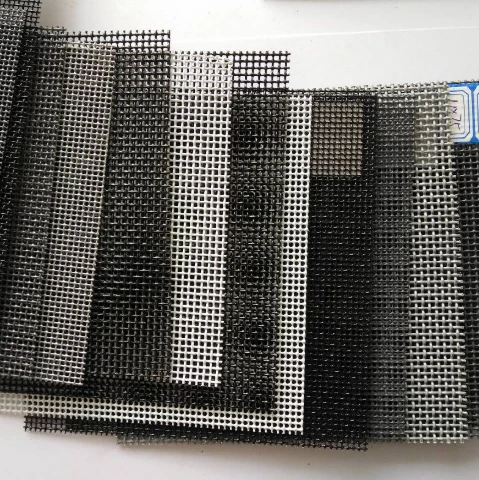

(galvanized metal mesh)

Understanding Galvanized Metal Mesh: Strength and Protection

Galvanized metal mesh delivers unparalleled corrosion resistance through a zinc coating process that creates sacrificial protection when exposed to corrosive elements. The hot-dip galvanizing method provides 2-4 times longer service life than electro-galvanized alternatives, with coating thickness typically ranging from 70-90 microns for industrial-grade applications. ASTM A653 specifications govern this protective barrier that extends product lifespan to 25+ years in standard environments.

Galvanized expanded metal mesh offers exceptional strength-to-weight ratios, with diamond-shaped apertures providing up to 80% open area while maintaining structural rigidity. Common specifications include:

- SWD (Short Way of Design): Measures diamond pattern density (1/4" to 4" sizes)

- Material Thickness: 18-12 gauge (1.2mm-2.7mm) for industrial applications

- Coating Weight: Standard G90 coating (0.90 oz/ft² zinc coverage)

The cold-working manufacturing process maintains the steel's tensile strength between 50,000-80,000 psi, while providing burr-free edges that exceed OSHA safety standards. This makes galvanized mesh sheets ideal for applications requiring both security and airflow.

| Manufacturer |

Coating Method |

Tensile Strength |

Corrosion Resistance |

Lead Time |

Cost per m² |

| McNICHOLS |

Hot-dip |

65,000 psi |

Salt spray: 1500hrs |

2-3 weeks |

$28.75 |

| Direct Metals |

Pre-galvanized |

55,000 psi |

Salt spray: 750hrs |

1-2 weeks |

$24.30 |

| Marco Specialty |

Hot-dip + powder coat |

70,000 psi |

Salt spray: 2500hrs |

3-4 weeks |

$37.20 |

Precision slitting capabilities allow width customization up to 72 inches without compromising structural integrity, while specialized flattening processes reduce project footprint requirements by approximately 15%. These material innovations have positioned galvanized expanded metal mesh as a critical component in modern infrastructure projects.

Customization enables industry-specific adaptations:

- Architectural Facades: Fine mesh patterns (3/16" SWD)

- Heavy Industrial: 9-gauge reinforcing meshes

- Agricultural: Anti-microbial zinc-aluminum coatings

Implementation case studies demonstrate significant advantages:

- Portland Airport utilized galvanized metal mesh

partitions achieving 42% reduction in HVAC load requirements

- Seattle marine terminal installed specialized corrosion-resistant mesh, decreasing maintenance costs by $175,000 annually

- Automotive manufacturers reported 18% increased throughput using customized conveyor belt meshes

Proper installation requires minimal clearance of 1/8" between panel edges to accommodate thermal expansion. Fastening systems should employ zinc-plated hardware to prevent bimetallic corrosion - a critical detail ensuring 15-20 year service intervals before significant maintenance. Water drainage slope must exceed 3° minimum to prevent debris accumulation.

Corrosion prevention strategies include:

- Monthly fresh water rinsing in coastal environments

- Annual zinc-rich coating inspection using electromagnetic gauges

- Immediate treatment of scratches exceeding 5mm depth

Protective coating maintenance extends service life by approximately 8 years compared to untreated equivalents. Data-driven maintenance protocols can reduce lifecycle costs by 30-40% in aggressive environments.

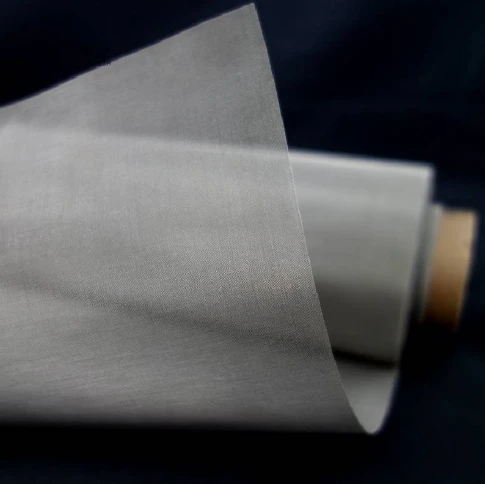

Future Applications for Galvanized Metal Mesh Sheets

Industry leaders forecast 6.2% annual growth for specialized galvanized meshes through 2028, driven by renewable energy installations and smart city infrastructure. Emerging applications include:

- Solar farm security screening requiring UV-stabilized coatings

- Modular construction systems with interlocking panel designs

- Electrically conductive meshes for EV battery cooling

The newest GA (Galvannealed) coating technology fuses zinc-iron alloys directly to steel substrates, improving paint adhesion while maintaining cathodic protection. This advancement reduces finishing costs by approximately 22% for architectural applications. Continuous innovation ensures galvanized metal mesh remains essential for projects prioritizing structural integrity and protective performance.

(galvanized metal mesh)

FAQS on galvanized metal mesh

Q: What are the common applications of galvanized metal mesh sheets?

A: Galvanized metal mesh sheets are widely used in construction, agriculture, and industrial settings for fencing, safety barriers, filtration, and reinforcement due to their corrosion resistance and durability.

Q: How does galvanized metal mesh differ from other types of metal mesh?

A: Galvanized metal mesh is coated with a protective zinc layer, making it highly resistant to rust and environmental damage compared to untreated or PVC-coated alternatives.

Q: Can galvanized expanded metal mesh be used for outdoor projects?

A: Yes, galvanized expanded metal mesh is ideal for outdoor use, such as walkways, grates, and security screens, thanks to its weather-resistant properties and structural strength.

Q: What maintenance is required for galvanized metal mesh products?

A: Minimal maintenance is needed. Periodically clean with water and mild detergent, and inspect for physical damage to ensure longevity.

Q: How do I choose between galvanized metal mesh sheets and expanded metal mesh?

A: Select sheets for flat surfaces or precise cutting, while expanded mesh is better for slip-resistant surfaces or projects requiring lightweight flexibility.