- Performance analysis and load capacity metrics

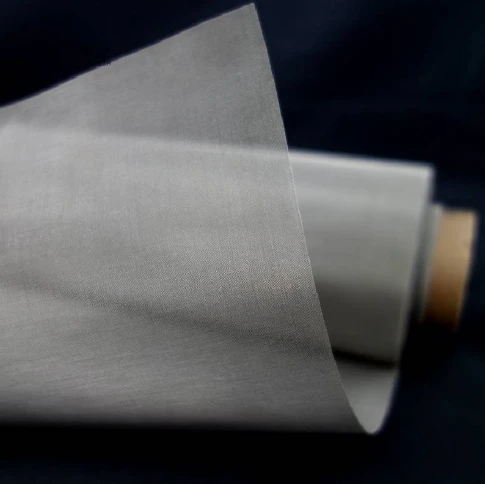

- Material composition and corrosion resistance properties

- Comparison of leading manufacturers

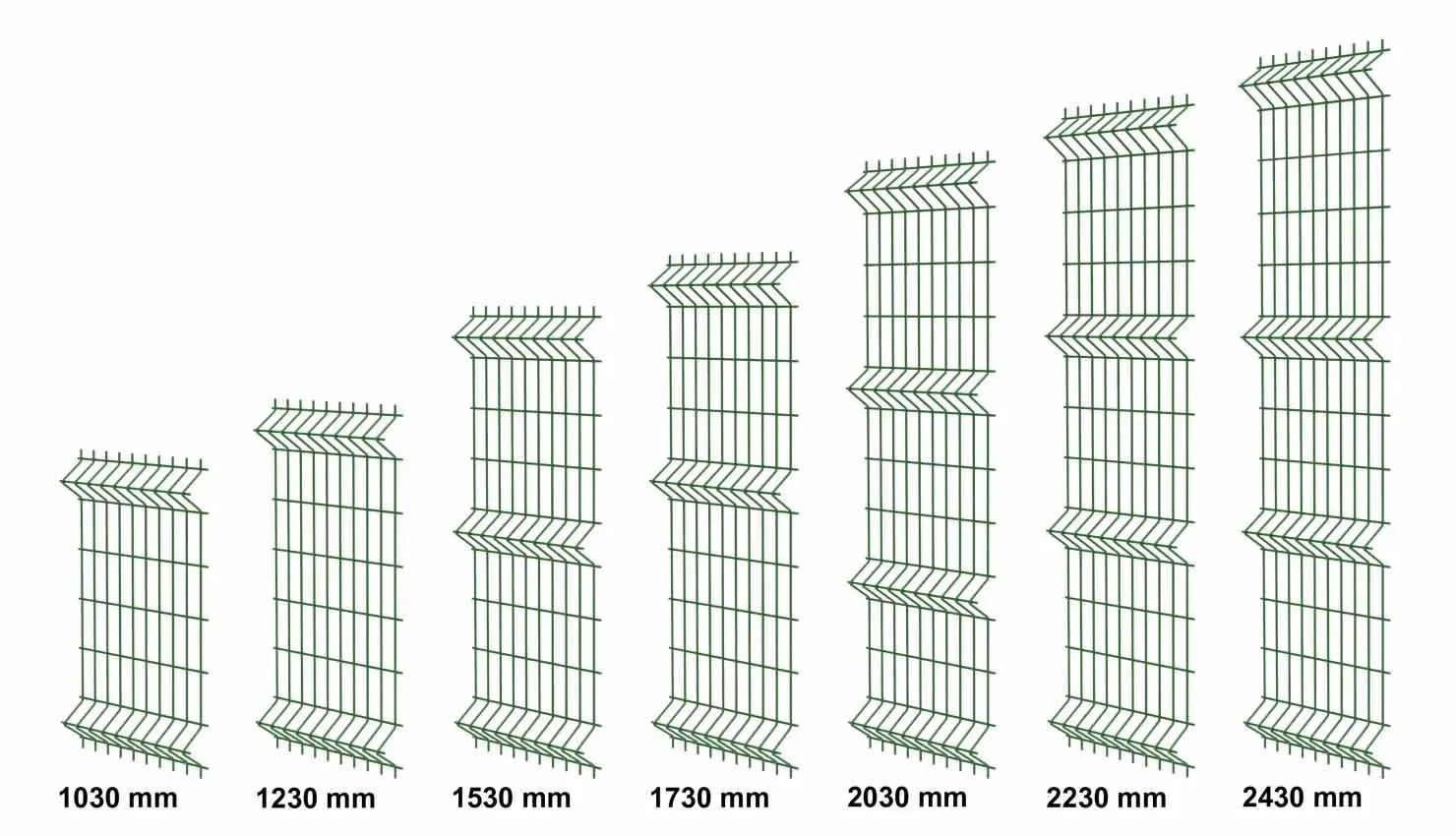

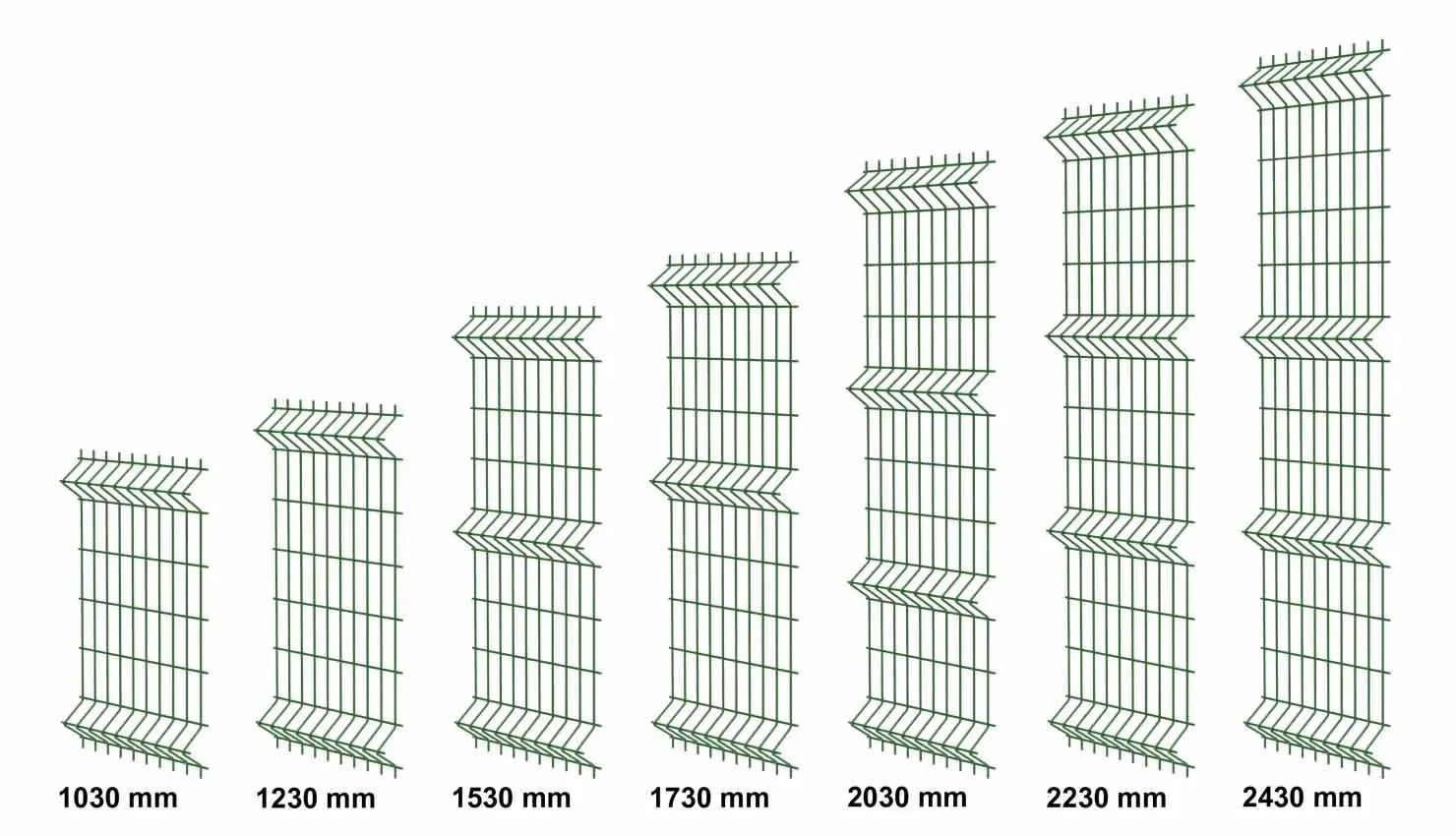

- Industry-specific customization options

- Practical application case studies

- Installation best practices

- Material selection guidance for project requirements

(4 welded wire mesh)

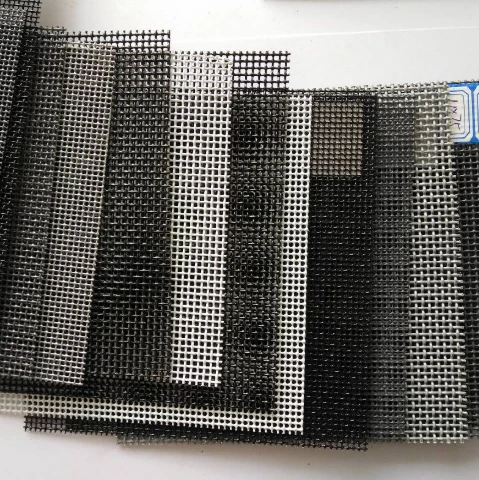

Understanding 1/4 inch Welded Wire Mesh Specifications

Welded wire mesh with 1/4" apertures serves as a fundamental material across multiple industrial sectors due to its exceptional structural properties. Constructed from intersecting steel wires joined through electric resistance welding, the resulting grid formation offers uniform strength distribution. For 1/4" welded wire mesh, standard wire diameters range between 0.028" and 0.063" (22-14 gauge), with tensile strength ratings from 65,000 to 80,000 psi. Laboratory tests demonstrate that properly galvanized 1/4" mesh withstands over 1,200 hours in salt spray tests before initial red rust formation. Load-bearing capacities vary significantly by configuration, with common industrial-grade 1/4" mesh panels supporting distributed loads exceeding 850 lbs/ft² without deformation. These characteristics explain the material's prevalence in filtration systems, security partitions, and concrete reinforcement applications where precision-engineered solutions are non-negotiable.

Technical Advantages in Construction Applications

The dimensional stability of welded wire mesh outperforms alternative materials in structural applications. Unlike expanded metal or chain link alternatives, the welded joints prevent slippage under stress, maintaining consistent opening sizes critical for screening operations. When embedded in concrete slabs, 1" welded wire mesh reduces crack propagation by 42% compared to non-reinforced surfaces according to ACI studies. The fusion-welded junctions create monolithic structures where load transfer occurs uniformly across the entire surface. Environmental resilience depends on protective treatments:

- Electro-galvanized coating (G90 standard): Minimum zinc coating of 0.90 oz/ft²

- Hot-dip galvanized coating: Average 1.85 oz/ft² zinc coverage

- Polymer coatings: 0.015"-0.025" thickness providing UV stability

Thermal contraction testing shows dimensional variance below 0.03% across temperatures from -40°F to 150°F, ensuring stability in extreme environments.

Manufacturing Processes and Quality Benchmarks

Production methodologies significantly impact performance characteristics of welded wire mesh:

| Aspect |

Industry Standard |

Commercial Grade |

Industrial Grade |

| Tensile Strength |

65,000 psi |

70,000 psi |

80,000+ psi |

| Welding Precision |

±0.05" tolerance |

±0.03" tolerance |

±0.015" tolerance |

| Coating Durability |

500 salt spray hours |

750 salt spray hours |

1,200+ salt spray hours |

| Panel Flatness |

≤1/8" variance |

≤1/16" variance |

≤1/32" variance |

Optical inspection systems automatically detect welding defects at production speeds exceeding 125 ft/min, guaranteeing consistent quality.

Application-Specific Customization Parameters

Customization transforms welded wire mesh from commodity to engineered solution through precise modifications:

- Geometric adaptation: Ovalization of 1" welded wire mesh openings for specific flow rates

- Edge treatments: Hemmed borders or continuous welds prevent unraveling

- Specialty alloys: 316L stainless steel for chlorine environments or grade 1008 carbon steel

- Hybrid compositions: Galvanized wire with PVC coating for exterior security fences

For agricultural applications requiring 1/4" welded wire mesh, manufacturers apply compression patterning that increases rigidity by 22% without adding material weight. Aerospace implementations utilize stress-relieving protocols where mesh undergoes thermal treatment after fabrication to relieve internal stresses.

Performance Validation in Industrial Case Studies

Field verifications demonstrate measurable outcomes using 4 welded wire mesh

systems:

- A highway construction project employed 1" welded wire mesh in concrete barrier walls, reducing reinforcement labor costs by 38% versus rebar mats

- Food processing facilities utilizing 1/4" welded wire mesh conveyor belts decreased maintenance downtime by 62% compared to plastic alternatives

- Security installations recorded 0% perimeter breaches after implementing double-layer galvanized mesh fencing

Material lifespan analyses indicate service durations from 7 years (uncoated interiors) to 25+ years (triple-protected exterior installations).

Material Specification Considerations

Optimal welded wire mesh selection requires analyzing critical variables:

Wire gauge selection formula: Gauge = [Required load capacity (lbs/ft²) ÷ 120] + 14

Corrosion variables:

- Environmental exposure classifications (C1-C5 categories per ISO 12944)

- Chemical contact probability

- Maintenance accessibility

Material composition determines physical properties - carbon steel provides maximum rigidity while stainless steel offers superior corrosion resistance. Fabrication methodology influences structural stability: robotic welding creates homogeneous connections versus spotty manual welds.

Selecting Appropriate Welded Wire Mesh Specifications

Implementation protocols for 1 4 welded wire mesh should follow project-specific validation parameters:

- Confirm ASTM A185 compliance for concrete applications

- Specify hot-dip galvanized treatments for exterior applications

- Validate aperture consistency through certified measurement reports

Standard sheet sizes for 4 welded wire mesh typically measure 4' × 8' (industrial) or 5' × 150' rolls (agricultural), though custom dimensions are manufactured with minimal dimensional tolerances (±0.015"). Performance warranties vary from 1 year (commercial grade) to 15 years (industrial applications) depending on environmental conditions and installation methodology.

(4 welded wire mesh)

FAQS on 4 welded wire mesh

Q: What is the typical application of 4 welded wire mesh?

A: 4 welded wire mesh is commonly used in industrial and agricultural settings for reinforcing concrete structures, fencing, and animal enclosures due to its durability and strength.

Q: How does 1 inch welded wire mesh differ from 1/4 inch welded wire mesh?

A: 1 inch welded wire mesh has larger openings, ideal for lightweight fencing or garden use, while 1/4 inch welded wire mesh offers finer spacing, suitable for pest control or small animal cages.

Q: Is 1/4 welded wire mesh corrosion-resistant?

A: Yes, 1/4 welded wire mesh is often galvanized or PVC-coated, providing corrosion resistance for outdoor applications like garden beds or aviaries.

Q: Can 1 4 inch welded wire mesh support heavy loads?

A: While 1/4 inch welded wire mesh is sturdy, it’s designed for moderate loads, such as rodent barriers or craft projects, not heavy structural reinforcement.

Q: What gauge thickness is available for 4 welded wire mesh?

A: 4 welded wire mesh typically ranges from 6 to 12 gauge, with thicker gauges (e.g., 6-8) used for heavy-duty applications like concrete slabs or security fencing.