Introduction to Advanced Stainless Steel Wire Mesh Solutions

In the realm of industrial filtration, separation, and structural reinforcement, the performance and reliability of materials are paramount. Among the most versatile and indispensable components is Stainless Steel Wire Mesh. Renowned for its exceptional durability, corrosion resistance, and adaptability, it serves as a critical asset across a myriad of B2B applications. This comprehensive article delves into the intricate world of stainless steel wire mesh, exploring its manufacturing processes, technical specifications, diverse application scenarios, and the strategic advantages it offers to modern industries. We will also address key considerations for procurement, including vendor comparison, customization options, and the vital role of quality assurance.

Our objective is to provide B2B decision-makers and engineers with a robust understanding of this essential product, highlighting its capacity to drive efficiency, longevity, and performance in demanding environments.

Industry Trends and Market Dynamics for Stainless Steel Wire Mesh

The global market for Stainless Steel Wire Mesh is characterized by a continuous drive towards enhanced performance, sustainability, and cost-effectiveness. Key trends shaping the industry include the increasing demand for advanced alloy compositions, particularly super duplex and specialized austenitic grades, to withstand extreme corrosive and high-temperature conditions in sectors like offshore oil & gas and chemical processing. Automation in manufacturing, including precision weaving and welding technologies, is leading to higher mesh accuracy and consistency, reducing material waste and improving product lifespan.

Furthermore, there is a growing emphasis on customized solutions. Clients increasingly require specific mesh counts, wire diameters, and weave patterns tailored to unique filtration requirements or architectural aesthetics. Digitalization is also playing a role, with advanced design software allowing for complex mesh structures and rapid prototyping. The market is projected to grow steadily, fueled by infrastructure development, stringent environmental regulations requiring sophisticated filtration systems, and the expanding applications in renewable energy and automotive industries.

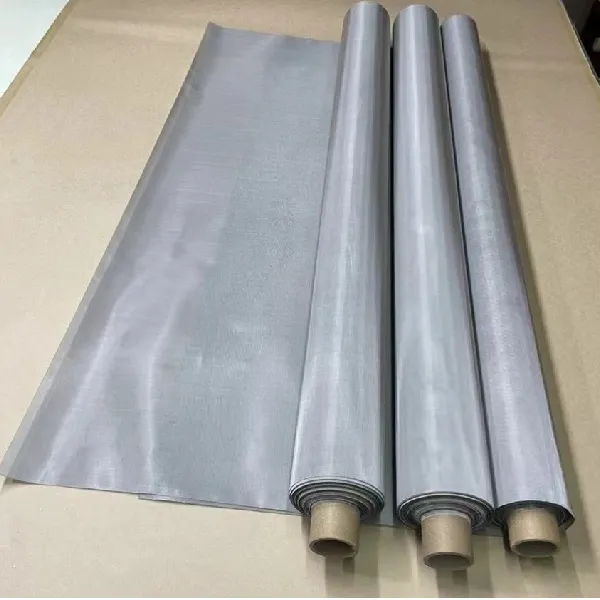

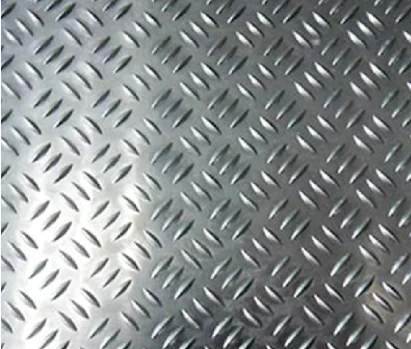

Precision weaving machines for high-quality Stainless Steel Wire Mesh production.

The Manufacturing Process of Stainless Steel Wire Mesh

The production of high-quality Stainless Steel Wire Mesh is a meticulous process, beginning with the selection of premium-grade stainless steel alloys. The most common grades include 304 (for general purpose, good corrosion resistance), 316 (enhanced corrosion resistance, especially against chlorides), and 316L (low carbon version of 316, ideal for welding applications and preventing carbide precipitation). The process typically involves several critical stages:

Process Flow Schematic:

-

1. Raw Material Sourcing & Inspection: High-purity stainless steel wire rods (e.g., AISI 304, 316, 316L) are sourced from certified mills. Each batch undergoes rigorous inspection for chemical composition, mechanical properties, and surface finish to ensure compliance with standards like ASTM A276/A580.

-

2. Wire Drawing: The wire rods are drawn through a series of dies to reduce their diameter to the desired gauge. This process not only achieves the required wire thickness but also enhances tensile strength and surface smoothness.

-

3. Annealing (Heat Treatment): After drawing, the wires may undergo annealing to relieve internal stresses, improve ductility, and restore their crystal structure, making them suitable for subsequent weaving or welding without fracturing.

-

4. Weaving/Welding:

-

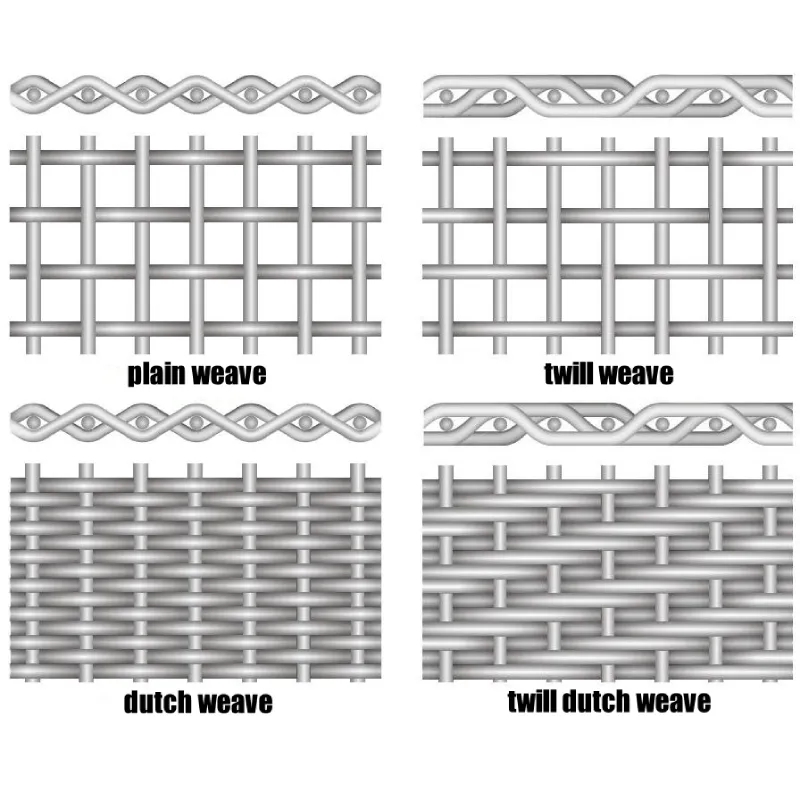

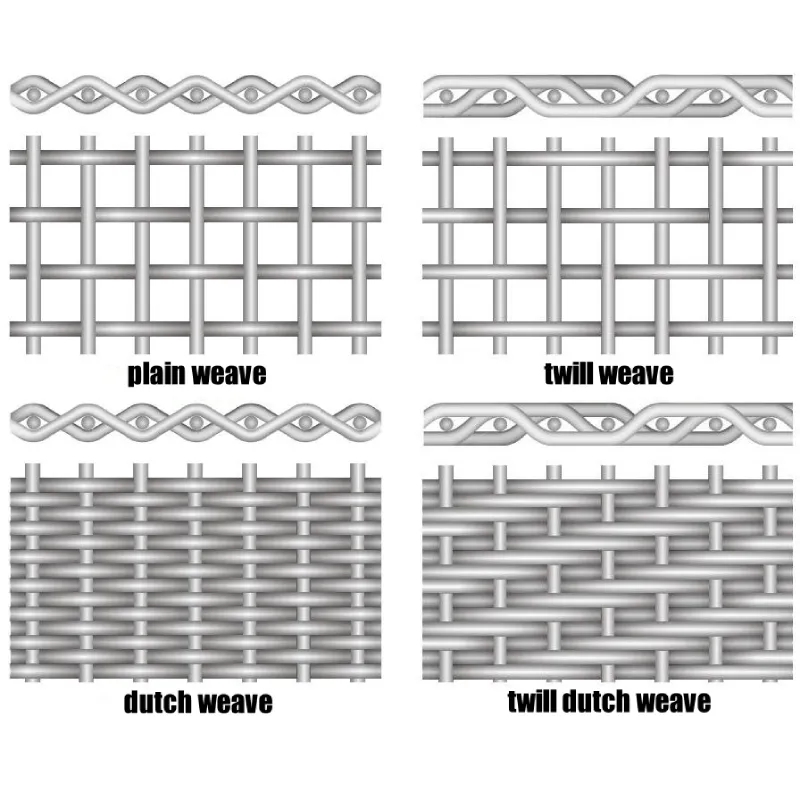

Weaving: Precision weaving looms interlace warp (longitudinal) and weft (transverse) wires to form various mesh patterns (e.g., plain weave, twill weave, Dutch weave). This is a precise mechanical process where wire diameters and mesh counts are meticulously controlled.

-

Welding: For welded mesh, individual wires are resistance-welded at each intersection, forming a strong, rigid structure. This is often used for heavier gauge wires and structural applications.

-

5. Cutting & Finishing: The woven or welded mesh rolls are cut to specified dimensions. Secondary finishing processes may include trimming, degreasing, cleaning, and passivation (acid treatment to restore the passive chromium oxide layer for enhanced corrosion resistance).

-

6. Quality Control & Testing: Each finished product undergoes stringent quality checks. This includes visual inspection, mesh count verification, wire diameter measurement, opening size accuracy, and mechanical property tests (e.g., tensile strength, elongation). Compliance with international standards such as ISO 9044, ASTM E2016, and ANSI B74.18 is ensured. Our products are designed for long service life, typically exceeding 10-20 years depending on the application environment, demonstrating exceptional corrosion resistance and minimal degradation even in harsh conditions.

-

7. Packaging & Dispatch: Products are carefully packaged to prevent damage during transit and dispatched to target industries like petrochemical, metallurgy, water supply & drainage, and food processing, where their advantages in energy saving through optimized filtration and superior corrosion resistance are critical.

Technical Specifications and Performance Parameters

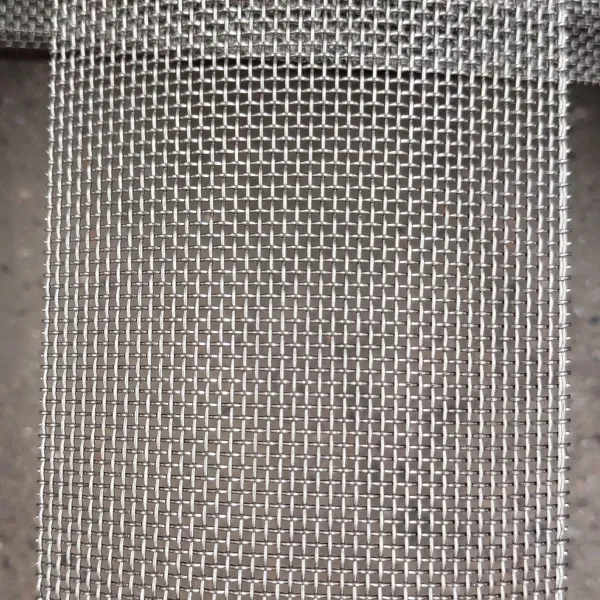

The effectiveness of Stainless Steel Wire Mesh is defined by a range of technical specifications and performance parameters, each critical for its intended application. Understanding these parameters is key to selecting the optimal mesh for specific industrial requirements.

Key Parameters:

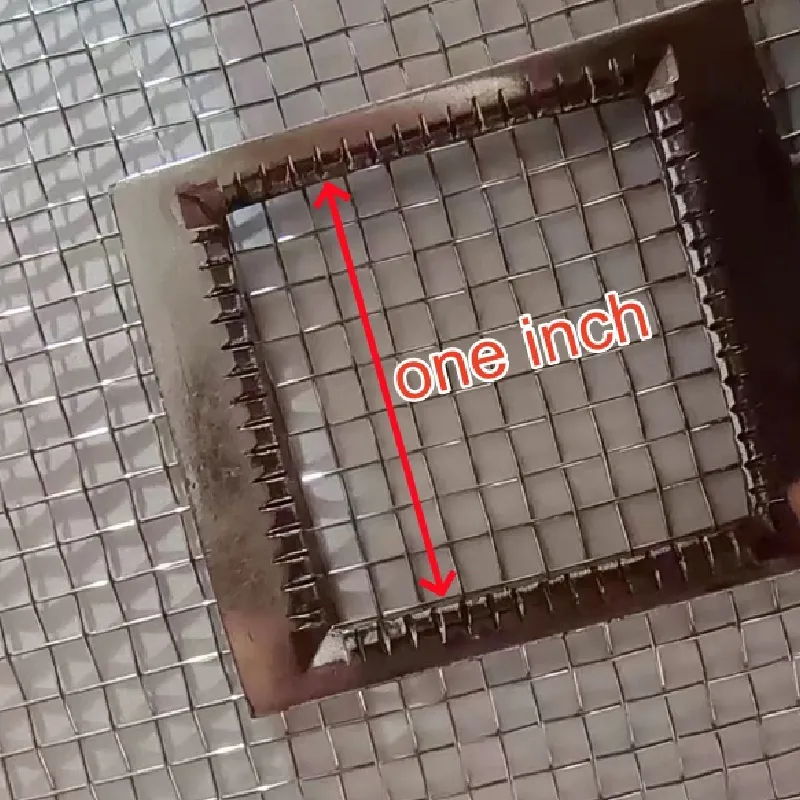

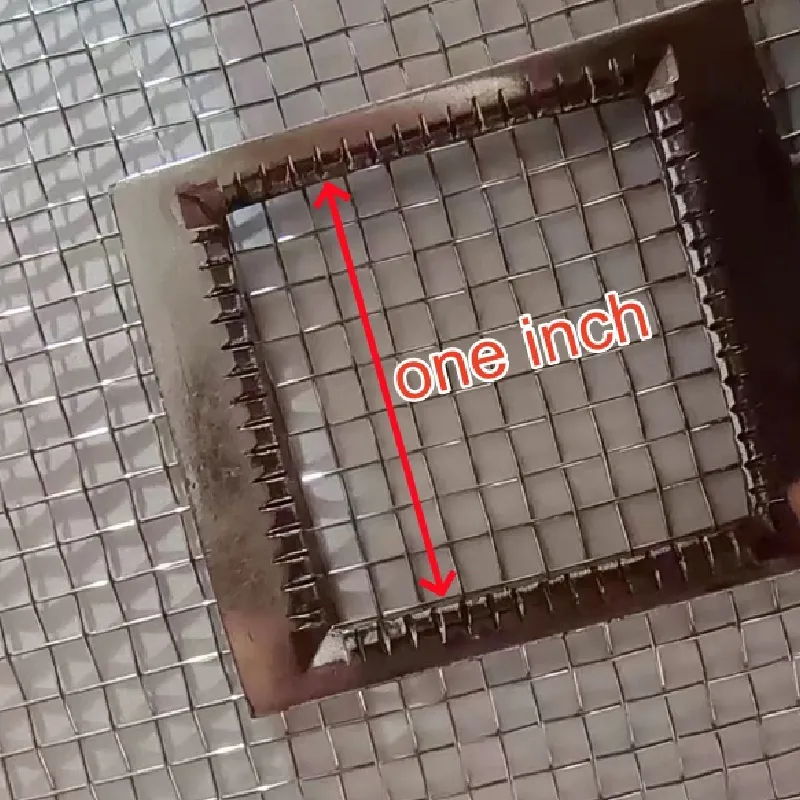

- Mesh Count: The number of openings per linear inch, indicating the fineness of the mesh. Higher mesh counts mean smaller openings and finer filtration.

- Wire Diameter: The thickness of the individual wires. Thicker wires provide greater strength and durability, while thinner wires offer more open area and finer filtration.

- Opening Size (Aperture): The clear space between adjacent wires, directly related to filtration efficiency.

- Weave Type: Determines the structure and properties of the mesh. Common types include Plain Weave (simple, robust), Twill Weave (stronger, able to hold heavier wires), and Dutch Weave (very fine filtration, high strength, often used for pressure filtration).

- Material Grade: Specifies the stainless steel alloy (e.g., 304, 316, 316L), influencing corrosion resistance, temperature tolerance, and mechanical strength.

- Open Area: The percentage of open space in the mesh, impacting flow rate and filtration capacity. Higher open area allows for greater flow.

- Tensile Strength: The maximum stress the material can withstand while being stretched or pulled before breaking.

Typical Stainless Steel Wire Mesh Specification Table (Example):

| Parameter |

Typical Range (Standard Mesh) |

Impact on Performance |

| Material Grade |

SS304, SS316, SS316L |

Corrosion resistance, heat resistance, weldability. |

| Mesh Count |

2 mesh to 635 mesh per inch |

Filtration precision, particle retention. |

| Wire Diameter |

0.02mm to 6.0mm |

Strength, open area, flow rate. |

| Aperture (Opening Size) |

25 microns to 10mm |

Particle separation efficiency. |

| Weave Type |

Plain, Twill, Dutch (Plain/Twill) |

Strength, filtration characteristics, stability. |

| Open Area (%) |

Approx. 20% to 80% |

Flow capacity, pressure drop. |

| Tensile Strength (MPa) |

515 - 860 (depending on grade/temper) |

Structural integrity, resistance to stress. |

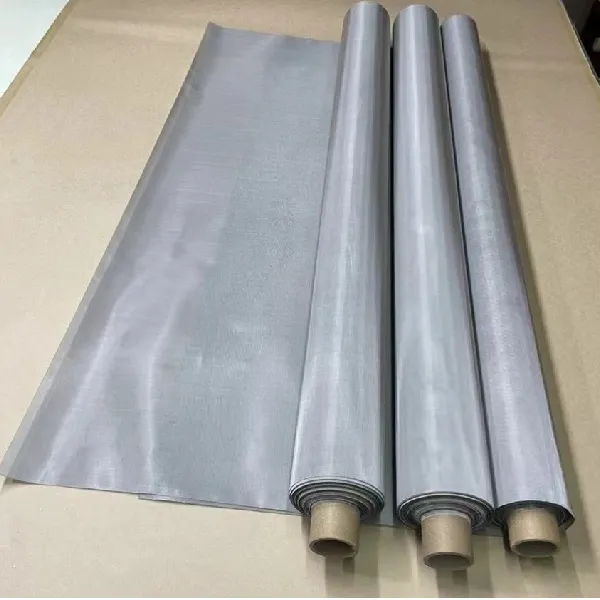

A close-up view revealing the precise weave of Stainless Steel Wire Mesh.

Key Technical Advantages of Stainless Steel Wire Mesh

The inherent properties of stainless steel, combined with advanced manufacturing techniques, bestow Stainless Steel Wire Mesh with a suite of unparalleled technical advantages making it a preferred material across diverse industrial applications:

- Superior Corrosion Resistance: Stainless steel, particularly grades like 316 and 316L, offers exceptional resistance to oxidation, rust, and various chemical aggressors, including acids, alkalis, and chlorides. This characteristic significantly extends product service life in harsh environments such as marine, chemical processing, and wastewater treatment.

- High Temperature Endurance: Stainless steel maintains its structural integrity and mechanical properties even at elevated temperatures, making it suitable for applications involving hot gases, liquids, or components within high-temperature industrial processes.

- Robust Mechanical Strength: With high tensile strength and ductility, stainless steel wire mesh can withstand significant mechanical stress, vibration, and impact without deformation or breakage, ensuring reliable performance in demanding structural and filtration roles.

- Excellent Hygiene and Cleanability: The smooth, non-porous surface of stainless steel inhibits bacterial growth and allows for easy cleaning and sterilization, which is critical in food & beverage, pharmaceutical, and medical applications. This contributes to enhanced product purity and safety.

- Dimensional Stability & Precision: Advanced weaving and welding techniques ensure high dimensional accuracy and consistent aperture sizes, guaranteeing reliable and repeatable filtration or separation efficiency.

- Long Service Life & Low Maintenance: Due to its inherent durability and resistance to degradation, stainless steel wire mesh provides an extended operational lifespan, reducing the need for frequent replacement and associated maintenance costs. This translates directly into lower total cost of ownership (TCO) and improved operational efficiency.

- Recyclability: As a sustainable material, stainless steel is 100% recyclable, aligning with modern industrial environmental responsibility initiatives.

Diverse Application Scenarios & Target Industries

The versatility of Stainless Steel Wire Mesh makes it indispensable across a vast array of industrial sectors and application scenarios, driven by its unique combination of strength, corrosion resistance, and precise filtration capabilities.

Key Industries and Applications:

- Petrochemical and Chemical Processing: Used for catalyst support grids, filter elements in reactors, strainers for corrosive fluids, and separation of chemical compounds. Its resistance to harsh chemicals ensures operational safety and longevity.

- Water Treatment and Wastewater Management: Employed in pre-filtration, primary screening, dewatering, and as support for filter media in municipal and industrial water treatment plants. Ensures effective removal of particulates, contributing to water purity and system efficiency.

- Metallurgy and Mining: Essential for screening and sizing aggregates, ores, and crushed materials. Also used in vibrating screens, conveyor belt guards, and separation processes in mineral processing plants, offering robust performance against abrasion.

- Food and Beverage Industry: Critical for filtration in brewing, dairy, fruit juice production, and sugar refining. Used in sieves, strainers, and conveyor belts due to its hygienic properties, ease of cleaning, and resistance to food acids and sanitizers.

- Pharmaceutical and Medical: Utilized for precise filtration of active pharmaceutical ingredients (APIs), sterile air filtration, and in surgical instrument sterilization trays. The non-contaminating and cleanable nature is paramount for compliance with stringent health standards.

- Architectural and Decorative: Beyond industrial uses, stainless steel wire mesh is increasingly adopted for aesthetic and functional purposes in modern architecture, including building facades, balustrades, sunscreens, and decorative panels, owing to its sleek appearance and durability.

- Automotive and Aerospace: Found in fuel filters, air filters, exhaust system components, and as protective screens in engine compartments, where high temperature and corrosion resistance are vital.

- Oil and Gas: Used in sand control screens, well screens, filter elements for drilling fluids, and separation equipment on offshore platforms, enduring high pressures and corrosive media.

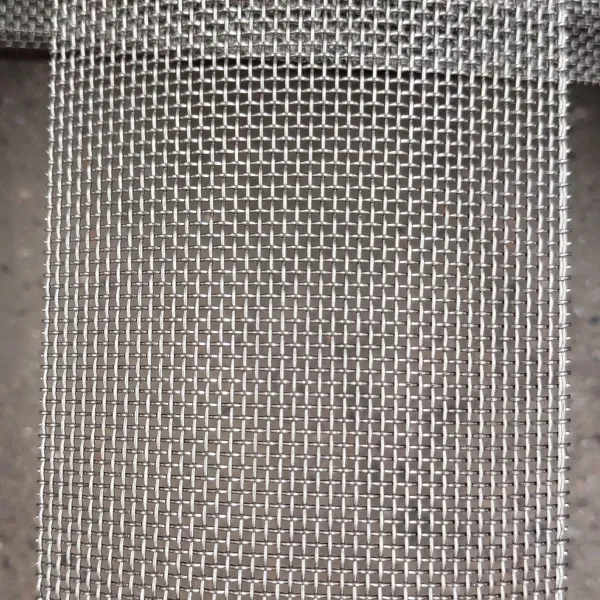

Stainless Steel Wire Mesh acting as a robust filtration barrier in industrial settings.

Customized Solutions for Specialized Requirements

While standard Stainless Steel Wire Mesh offers broad utility, many industrial applications necessitate highly specific configurations. Our approach to client partnerships emphasizes bespoke solutions, understanding that optimal performance is often achieved through precise customization. We offer comprehensive capabilities to tailor wire mesh products to exact project specifications.

Customization Capabilities Include:

- Material Grade Selection: Beyond standard 304, 316, and 316L, we provide options for specialized alloys such as Duplex Stainless Steel (2205), Super Duplex (2507), or exotic alloys for extreme conditions of corrosion, temperature, or pressure.

- Specific Mesh Counts & Wire Diameters: Precision manufacturing allows for the creation of mesh with extremely fine or coarse counts, combined with precise wire diameters, to meet exact filtration or structural criteria.

- Specialized Weave Patterns: In addition to plain, twill, and Dutch weaves, we can produce reverse Dutch weave for finer filtration, crimped wire mesh for enhanced stability, or even multi-layer composite meshes for complex applications.

- Custom Dimensions & Fabrication: Mesh can be supplied in rolls, sheets, or precisely cut-to-size pieces. Further fabrication includes stamping, bending, welding, and forming into baskets, cylinders, cones, or other complex shapes.

- Surface Treatments: Options for electropolishing for ultra-smooth surfaces, PTFE coating for anti-stick properties, or other specialized finishes to enhance performance or aesthetic appeal.

- Edge Treatment: Custom edge finishing to prevent fraying, enhance safety, or facilitate integration into larger assemblies.

Our engineering team collaborates closely with clients to understand the specific operational parameters, environmental factors, and performance expectations to design and produce a wire mesh solution that delivers optimal results and long-term value.

Custom-fabricated Stainless Steel Wire Mesh filter elements for industrial machinery.

Vendor Comparison and Selection Criteria

Selecting the right supplier for Stainless Steel Wire Mesh is a critical decision that impacts project success, operational costs, and long-term reliability. A thorough vendor comparison should consider more than just price; it must encompass quality, expertise, and support.

Key Vendor Selection Criteria:

- Product Quality & Certifications: Verify adherence to international standards (ISO 9001, ASTM, DIN). Look for certifications of raw materials and finished products, and robust internal quality control processes.

- Manufacturing Capabilities: Assess the vendor's ability to produce the required mesh types, sizes, and quantities, including specialized weaving or welding techniques and custom fabrication.

- Technical Expertise & R&D: A reputable vendor will have a strong engineering team capable of offering technical advice, custom design, and problem-solving, indicative of their deep industry knowledge.

- Experience & Track Record: Longevity in the industry, a portfolio of successful projects, and positive client testimonials reflect reliability and proven performance. We have been serving the industry for over 15 years, building a strong reputation for quality and customer satisfaction.

- Customization & Flexibility: The ability to provide tailored solutions for unique application requirements is often a differentiator.

- Lead Time & Logistics: Evaluate the vendor's capacity for timely delivery, inventory management, and efficient logistics to minimize project delays.

- After-Sales Support & Warranty: Comprehensive warranty policies and responsive customer service for technical support or issue resolution are crucial.

Comparative Analysis of Key Stainless Steel Grades for Wire Mesh:

| Feature / Grade |

SS304 |

SS316 |

SS316L |

| Primary Alloying Elements |

Cr (18-20%), Ni (8-10.5%) |

Cr (16-18%), Ni (10-14%), Mo (2-3%) |

Cr (16-18%), Ni (10-14%), Mo (2-3%), Lower C (max 0.03%) |

| General Corrosion Resistance |

Good (Standard) |

Excellent (Superior to 304, especially in chlorides) |

Excellent (Similar to 316) |

| Pitting & Crevice Corrosion Resistance |

Moderate |

High (Due to Molybdenum) |

High (Similar to 316) |

| High Temperature Resistance |

Good (up to 870°C intermittent) |

Very Good (up to 925°C intermittent) |

Very Good (Similar to 316) |

| Weldability |

Excellent |

Good |

Excellent (Prevents carbide precipitation) |

| Typical Applications |

General purpose, food handling, architectural screens. |

Marine, chemical processing, pharmaceutical, medical. |

Welded components for corrosive environments, fine filtration. |

| Cost Factor (Relative) |

Base / Standard |

Higher than 304 |

Similar to 316, slightly higher for specific forms. |

A range of Stainless Steel Wire Mesh options for diverse industrial needs.

Application Case Studies & Success Stories

Real-world applications powerfully demonstrate the value and performance of Stainless Steel Wire Mesh. Here are a few examples showcasing its impact in diverse industries:

Case Study 1: Enhanced Filtration in Pharmaceutical Production

Challenge: A major pharmaceutical company required ultra-fine filtration for active pharmaceutical ingredients (APIs) to meet stringent purity standards, ensuring no particulate contamination. The existing nylon mesh filters had insufficient chemical resistance and limited service life, leading to frequent replacements and production downtime.

Solution: We provided custom-fabricated 316L Stainless Steel Dutch Weave Wire Mesh filters with a precise aperture of 20 microns. The 316L grade was selected for its superior corrosion resistance to various pharmaceutical solvents and its low carbon content, preventing sensitization during welding and ensuring biological inertness.

Result: The client experienced a significant improvement in product purity, exceeding regulatory requirements. Filter replacement frequency decreased by 70%, leading to a 30% reduction in maintenance costs and an increase in overall production efficiency. The filters demonstrated exceptional chemical resistance and extended service life.

Case Study 2: Durable Screening for Aggressive Mining Operations

Challenge: A large-scale mining operation needed durable screening solutions for highly abrasive iron ore processing. Standard steel screens were failing prematurely due to constant impact and wear, causing costly operational interruptions and safety concerns.

Solution: We engineered heavy-duty 304 Stainless Steel Crimped Wire Mesh screens with a large wire diameter (4mm) and specific square mesh openings. The crimped weave provided enhanced structural rigidity and impact resistance, while the 304 stainless steel offered excellent abrasion resistance and robust mechanical properties suitable for the harsh mining environment.

Result: The new screens exhibited an increased lifespan of over 200% compared to previous materials, drastically reducing downtime and replacement costs. The improved screening efficiency also led to a more consistent product output, enhancing the overall profitability of the mining operation.

Case Study 3: Corrosion-Resistant Filters for Offshore Oil & Gas

Challenge: An offshore oil platform required robust filter elements for seawater intake systems and crude oil separation. The highly saline and corrosive environment, coupled with high pressures, quickly degraded conventional filters, leading to frequent failures and expensive repairs.

Solution: We supplied specialized Duplex Stainless Steel (2205) Wire Mesh filter cartridges. Duplex stainless steel offers superior resistance to chloride-induced stress corrosion cracking and pitting, along with higher mechanical strength compared to standard austenitic grades. The mesh was designed for high-pressure differentials and optimized flow rates.

Result: The Duplex Stainless Steel Wire Mesh filters demonstrated exceptional performance in the harsh marine environment, enduring high pressures and corrosive media for an extended period. This resulted in a significant reduction in maintenance frequency and associated costs, improving the reliability and safety of the platform's critical systems.

Quality Assurance, Certifications, and Authoritativeness

Our unwavering commitment to quality is the cornerstone of our operations, ensuring that every batch of Stainless Steel Wire Mesh meets the most stringent industry standards and client expectations. We adhere to a comprehensive quality management system that encompasses every stage of the manufacturing process, from raw material sourcing to final product inspection.

Commitment to Excellence:

- ISO 9001 Certified: Our quality management system is certified to ISO 9001 standards, reflecting our dedication to consistent quality, continuous improvement, and customer satisfaction.

- ASTM & DIN Compliance: All products are manufactured and tested in strict accordance with relevant ASTM (American Society for Testing and Materials) and DIN (Deutsches Institut für Normung) specifications, ensuring compatibility and performance with global industrial requirements.

- Rigorous Testing Protocols: Our in-house laboratory conducts comprehensive tests including chemical composition analysis, tensile strength, elongation, mesh count accuracy, and aperture size verification using precision optical equipment. This ensures that every roll or sheet delivered meets precise specifications.

- Material Traceability: We maintain full traceability of all raw materials from certified mills, providing material test reports (MTRs) and certificates of conformity (CoC) upon request, guaranteeing the authenticity and quality of the stainless steel used.

- Trusted by Industry Leaders: Over our 15+ years in the industry, we have established long-standing partnerships with leading companies in the petrochemical, water treatment, food & beverage, and mining sectors, a testament to our reliability and product performance.

- Continuous Improvement: We invest in research and development to advance our manufacturing processes and product offerings, incorporating the latest technological innovations and industry best practices. Our engineers regularly publish technical notes and collaborate with academic institutions to stay at the forefront of material science.

Quality inspection of Stainless Steel Wire Mesh to ensure precise specifications.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for custom Stainless Steel Wire Mesh orders?

A: Lead times vary depending on the complexity, quantity, and specific customization requirements. For standard products, our lead time typically ranges from 2-4 weeks. For highly customized or large-volume orders, it may extend to 6-8 weeks. We work closely with clients to provide accurate estimates and prioritize urgent requirements.

Q2: What kind of warranty do you offer on your Stainless Steel Wire Mesh products?

A: We stand behind the quality of our products. We offer a standard 12-month warranty against manufacturing defects from the date of purchase. Specific project warranties or extended warranty options can be discussed for large-scale or long-term supply agreements.

Q3: Can Stainless Steel Wire Mesh be used in high-temperature applications?

A: Yes, stainless steel is well-suited for high-temperature environments. Grades like SS304 can withstand intermittent temperatures up to 870°C (1600°F) and continuous temperatures up to 925°C (1700°F) for SS316. For extreme temperatures, specialized alloys can be considered. The specific temperature resistance depends on the grade and application conditions.

Q4: What are the best practices for cleaning and maintaining Stainless Steel Wire Mesh?

A: For optimal service life, clean regularly with mild detergents and water, using a soft brush or cloth. Avoid abrasive cleaners or steel wool which can damage the passive layer and lead to rust. For stubborn stains, specialized stainless steel cleaners or passivation treatments can be applied. Always rinse thoroughly after cleaning.

Q5: How do I determine the correct mesh count for my filtration needs?

A: Selecting the correct mesh count depends on the desired particle retention size (aperture), flow rate requirements, and the characteristics of the material being filtered. Our technical sales team can assist you in determining the ideal mesh count and wire diameter based on your specific application parameters and desired filtration efficiency.

Logistics, Warranty, and Dedicated Customer Support

We understand that reliable supply chain management and responsive support are as critical as product quality for our B2B partners. Our commitment extends beyond manufacturing to ensure a seamless experience from inquiry to post-purchase.

Efficient Logistics & Fulfillment:

- Global Reach: With established logistics networks, we offer worldwide shipping capabilities, ensuring timely delivery to diverse geographic locations.

- Packaging Excellence: All Stainless Steel Wire Mesh products are meticulously packaged to prevent damage during transit, utilizing robust materials and methods tailored to the product's form (rolls, sheets, fabricated components).

- Inventory Management: We maintain a strategic inventory of popular stainless steel grades and mesh configurations to expedite order fulfillment for standard products.

Comprehensive Warranty & After-Sales Support:

- Product Warranty: We provide a comprehensive warranty against defects in material and workmanship, ensuring peace of mind for our clients. Full details of our warranty policy are available upon request.

- Dedicated Account Management: Each client is assigned a dedicated account manager to streamline communication and provide personalized service throughout the entire project lifecycle.

- Technical Assistance: Our team of experienced engineers and technical specialists is available to offer expert advice on product selection, application optimization, and troubleshooting, ensuring our clients derive maximum value from our products.

- Responsive Customer Service: We pride ourselves on prompt and effective resolution of any queries or concerns, committed to maintaining long-term, trust-based relationships with our partners.

Conclusion

The utility and strategic importance of Stainless Steel Wire Mesh in modern industrial applications cannot be overstated. From its meticulous manufacturing process ensuring precise technical specifications to its wide-ranging application across critical sectors like petrochemical, water treatment, and pharmaceuticals, stainless steel wire mesh consistently delivers unparalleled performance. Its inherent advantages in corrosion resistance, high-temperature endurance, mechanical strength, and hygiene contribute significantly to operational efficiency, system longevity, and overall cost reduction for B2B enterprises.

By focusing on customized solutions, adhering to rigorous quality standards, and providing robust technical and logistical support, we empower our clients to achieve their most demanding project objectives. As industries continue to evolve, the demand for high-performance, reliable, and sustainable materials will only grow, cementing the role of stainless steel wire mesh as an indispensable component in the engineering landscape of tomorrow.

References

- ASM International. (2001). ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- ISO 9044:2016. Industrial woven wire cloth – Technical requirements and testings. International Organization for Standardization.

- ASTM International. (2019). ASTM E2016: Standard Terminology Relating to Sieves, Sieving, Wire Cloth and Perforated Plate for Sieving Purposes. ASTM International.

- Bradford, S. (1993). Corrosion Control. Van Nostrand Reinhold.

- The Materials Information Society (TMS). Duplex Stainless Steels: History, Properties, and Applications.