Understanding Expanded Metal Mesh: A Comprehensive Overview

In the realm of advanced material solutions for industrial and architectural applications, Expanded Metal Mesh stands out as a versatile, cost-effective, and highly functional material. Produced through a unique cold-forming process, it offers exceptional strength-to-weight ratios, superior light and air permeability, and inherent slip resistance. This detailed guide explores its manufacturing intricacies, technical specifications, diverse applications, and the benefits it brings to various sectors, positioning it as an indispensable component in modern engineering and design.

The Manufacturing Process of Expanded Metal Mesh

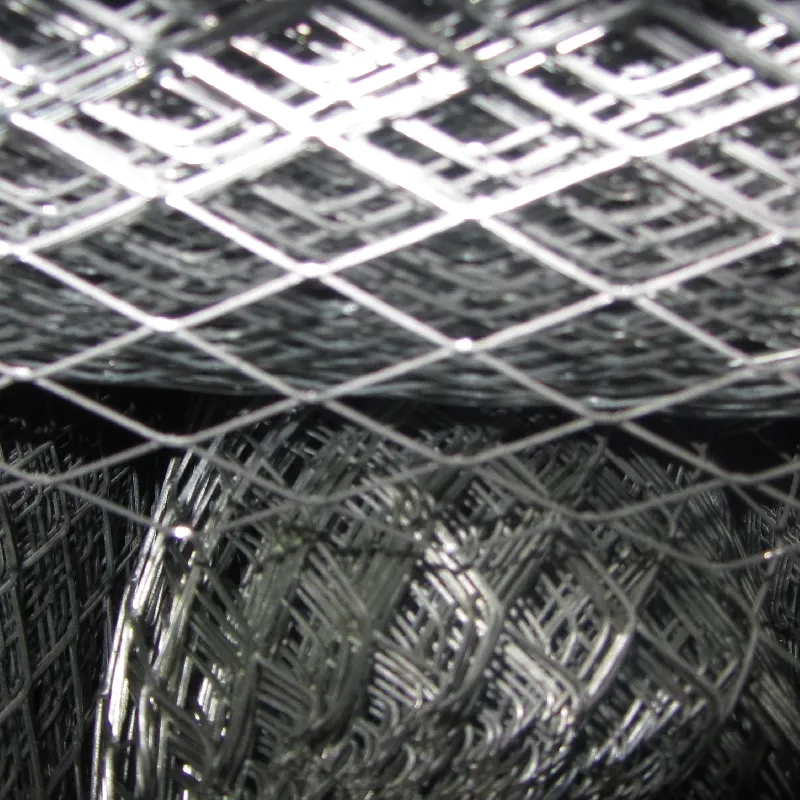

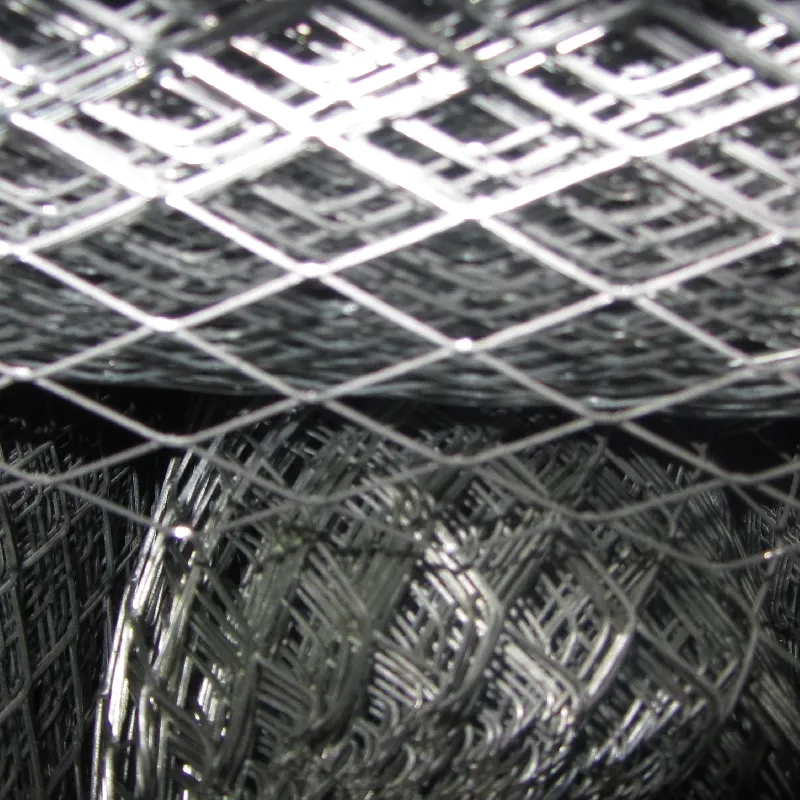

The production of Expanded Metal Mesh is a precision-driven cold-forming operation that transforms solid metal sheets into a mesh structure without material loss. This inherent efficiency contributes significantly to its cost-effectiveness and sustainability profile. The core process involves slitting and stretching, distinct from weaving or welding, which results in a monolithic, joint-free product.

Key Process Steps:

-

Material Selection: The process begins with selecting high-quality metal sheets. Common materials include carbon steel (mild steel), stainless steel (grades 304, 316, 316L for enhanced corrosion resistance), aluminum alloys (for lightweight applications), galvanized steel (for added durability), and occasionally nickel, copper, or titanium for specialized environments. Material choice is critical and dictated by the intended application's environmental conditions, load requirements, and aesthetic needs.

-

Shearing and Slitting: The selected metal sheet is fed into an expanding machine. Precision dies then simultaneously slit and stretch the metal. Unlike punching, no material is removed; instead, the slits are made in an offset pattern.

-

Expanding: Immediately after slitting, the sheet is stretched, causing the slits to open into diamond-shaped or hexagonal apertures. This stretching action elongates the original material, creating a rigid, integral mesh pattern. The resulting strands and bonds are formed without any welds or interlocks, ensuring exceptional structural integrity.

-

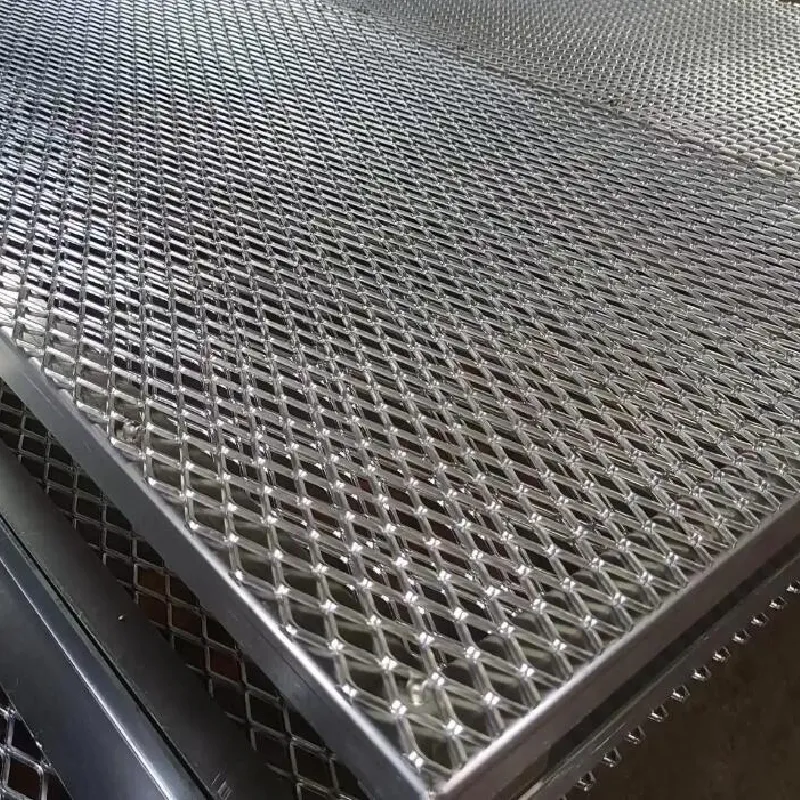

Flattening (Optional): For specific applications requiring a smoother surface, the expanded mesh can undergo a cold rolling process. This flattening reduces the overall thickness and provides a more uniform, flat surface, often referred to as "flattened expanded metal." Non-flattened mesh is known as "standard" or "raised" expanded metal and retains its inherent angular strands, offering superior grip and anti-skid properties.

-

Finishing and Treatment: Post-expansion, the mesh may undergo various finishing processes depending on its application. These include degreasing, pickling, galvanizing (hot-dip or electro-galvanizing), powder coating, PVC coating, anodizing (for aluminum), or painting. These treatments enhance corrosion resistance, improve aesthetics, and increase durability.

Testing Standards: Throughout production, adherence to international standards is paramount. Key standards include ASTM F1267 (Standard Specification for Metal, Expanded, Steel) for general expanded metal, and ISO 9001 for quality management systems, ensuring consistent product quality and performance. Material composition is verified against relevant ASTM or EN standards.

Service Life: The service life of Expanded Metal Mesh is exceptionally long, often exceeding 20-30 years, especially when appropriate materials and finishes are selected for the operating environment. For instance, hot-dip galvanized steel mesh can withstand harsh outdoor conditions for decades, while stainless steel offers superior performance in corrosive or high-temperature environments.

Industry Trends and Market Dynamics

The market for Expanded Metal Mesh is experiencing robust growth, driven by several macro-economic and industrial trends. Global urbanization, rapid industrialization, and significant investments in infrastructure development (e.g., transportation networks, energy facilities, public utilities) are key demand drivers.

- Sustainability Focus: There's an increasing emphasis on sustainable building materials and processes. Given that expanded metal production involves no material waste, it aligns well with circular economy principles. Its ability to facilitate natural ventilation and light penetration also contributes to energy efficiency in buildings, making it a preferred choice for green construction.

- Technological Advancements: Continuous innovation in manufacturing processes allows for greater precision, larger sheet sizes, and more intricate mesh patterns. Automation and advanced quality control systems are enhancing product consistency and reducing production costs.

- Customization and Aesthetics: Beyond traditional industrial uses, expanded metal is gaining traction in architectural and design applications. Architects and designers are increasingly leveraging its aesthetic versatility, creating unique facades, decorative panels, and interior elements. This trend demands higher levels of customization in terms of material, mesh pattern, color, and finish.

- Safety and Security: Heightened global security concerns are boosting demand for expanded metal in perimeter fencing, security cages, and anti-climb barriers, particularly in critical infrastructure and high-security installations. Its robust, non-climbable nature and clear visibility properties are highly valued.

According to industry reports, the global expanded metal market is projected to grow at a Compound Annual Growth Rate (CAGR) of over 5% from 2023 to 2030, driven predominantly by the construction, oil & gas, and manufacturing sectors. This growth underscores the material's adaptability and expanding utility.

Technical Specifications and Parameters of Expanded Metal Mesh

Understanding the technical parameters of Expanded Metal Mesh is crucial for proper material selection and engineering design. These parameters define the mesh's physical properties, performance characteristics, and suitability for specific applications.

Key Parameters:

- LWD (Long Way of Design): The measurement of the long diagonal of the diamond opening, from a point to a point.

- SWD (Short Way of Design): The measurement of the short diagonal of the diamond opening, from a point to a point.

- Strand Width: The width of the individual metal strips forming the mesh. This affects the mesh's strength and open area.

- Thickness (Gauge): The original thickness of the metal sheet before expansion.

- Overall Thickness: For standard (raised) mesh, this is the distance from the top surface to the bottom surface of the mesh. For flattened mesh, it is closer to the original sheet thickness.

- Weight per Square Meter: A critical parameter for load-bearing applications, calculated based on material density, original sheet thickness, strand width, LWD, and SWD.

- Open Area Percentage: The ratio of open space to total surface area, influencing light, air, and liquid passage.

Typical Product Specification Table (Example):

| Parameter |

Standard Carbon Steel Mesh |

Flattened Stainless Steel (304) Mesh |

Aluminum Architectural Mesh |

| Material |

Q235 Carbon Steel |

SS304 |

Alloy 1060/3003 |

| LWD x SWD (mm) |

50 x 25 |

20 x 10 |

75 x 30 |

| Original Thickness (mm) |

3.0 |

1.5 |

2.5 |

| Strand Width (mm) |

3.0 |

1.8 |

3.5 |

| Weight (kg/m²) approx. |

10.5 |

5.2 |

4.1 |

| Open Area (%) approx. |

70% |

65% |

78% |

Diverse Application Scenarios and Technical Advantages

The unique characteristics of Expanded Metal Mesh make it an incredibly versatile material, finding application across a multitude of industries. Its inherent properties translate into significant technical advantages for diverse operational environments.

Primary Target Industries:

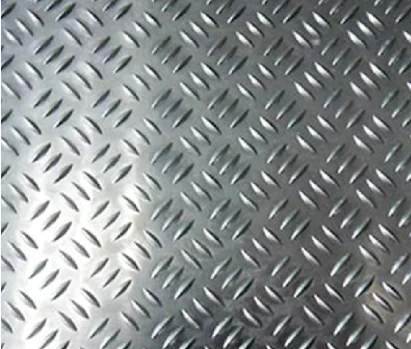

- Petrochemical & Energy: Ideal for walkways, platforms, stair treads, and safety barriers in refineries, power plants, and offshore rigs, where anti-skid properties and structural integrity are paramount. Its open structure allows for efficient drainage and air circulation.

- Metallurgy & Mining: Used in screening, sieving, and guarding machinery due to its durability and resistance to abrasion.

- Water Supply & Drainage: Employed in filter screens, gratings for drainage systems, and wastewater treatment plants due to its robust nature and ability to filter solids effectively while resisting corrosion (especially stainless steel and galvanized variants).

- Architectural & Construction: Utilized for building facades, sunscreens (energy saving through solar shading), ceilings, partitions, railings, and decorative elements. Its aesthetic appeal combined with functionality makes it a favored material.

- Automotive & Transportation: Found in vehicle grilles, anti-glare screens on highways, and fencing along transportation corridors.

- Security & Safety: Extensive use in high-security fencing, window guards, machine guards, and safe enclosures due to its cut-resistant, integral construction.

Technical Advantages in Application Scenarios:

- Energy Saving: When used as sunscreens or building facades, expanded metal can significantly reduce solar heat gain, minimizing the need for air conditioning and contributing to overall energy efficiency. Its open structure allows for airflow, promoting natural ventilation.

- Corrosion Resistance: By selecting materials like stainless steel (e.g., SS316L for marine or chemical environments) or applying hot-dip galvanization, expanded metal offers exceptional resistance to rust and degradation, ensuring longevity in harsh, corrosive conditions such as coastal areas, industrial facilities, or wastewater treatment plants.

- High Strength-to-Weight Ratio: The expansion process redistributes the metal, providing significant structural integrity from a comparatively lightweight sheet. This makes it ideal for applications where load-bearing capacity is crucial but weight is a concern, such as elevated platforms or catwalks.

- Anti-Skid Properties: The raised strands of standard expanded metal provide excellent traction, making it an ideal choice for walking surfaces, ramps, and stair treads, reducing the risk of slips and falls in industrial settings.

- Excellent Permeability: Its open mesh allows for free passage of light, air, heat, and liquids, making it suitable for filters, ventilation grilles, and protective screens that don't impede flow.

- Cost-Effectiveness & Sustainability: The no-waste manufacturing process and efficient use of material result in a highly economical product. Its long service life further enhances its lifecycle cost benefits.

Customer Feedback Example: "For our new petrochemical facility's platforms, we needed a robust, slip-resistant, and corrosion-proof solution. TiKe Metal's expanded metal mesh in galvanized carbon steel exceeded our expectations. The installation was straightforward, and the performance in our highly demanding environment has been exemplary, ensuring worker safety and long-term durability." - Senior Project Engineer, Leading Petrochemical Firm.

Vendor Comparison and Customized Solutions

Selecting the right supplier for Expanded Metal Mesh is as crucial as specifying the material itself. A reliable vendor ensures quality, adherence to specifications, timely delivery, and responsive support. TiKe Metal distinguishes itself through a commitment to excellence and customer-centric solutions.

Key Considerations When Choosing a Vendor:

- Quality Certifications: Look for ISO 9001 certification, signifying a robust quality management system. Adherence to international standards (e.g., ASTM, ANSI, EN) is also vital.

- Production Capacity & Lead Time: A vendor with high production capacity and efficient logistics can meet large orders and tight deadlines. Typical lead times for standard mesh might be 1-2 weeks, while custom orders could range from 3-6 weeks depending on complexity.

- Customization Capabilities: The ability to provide bespoke mesh sizes, materials, finishes, and secondary fabrication (cutting, bending, welding) is crucial for specialized projects.

- Technical Expertise & Support: A knowledgeable team can offer expert advice on material selection, design optimization, and application challenges.

- Pricing & Value Proposition: While cost is a factor, prioritize the overall value, including product quality, service, and long-term durability.

Vendor Comparison Table (Illustrative):

| Feature/Criterion |

TiKe Metal |

Competitor X |

Competitor Y |

| ISO 9001 Certified |

✔ Yes |

✔ Yes |

✘ No |

| Customization (Material, Size, Finish) |

✔ Extensive |

Limited |

Basic |

| Typical Lead Time (Standard Orders) |

7-10 Days |

10-14 Days |

14-21 Days |

| After-Sales Support |

✔ Excellent |

Fair |

Minimal |

| Project Consultation & Engineering Support |

✔ Available |

Limited |

Not Offered |

TiKe Metal's extensive experience and modern manufacturing capabilities allow for unparalleled flexibility in delivering customized Expanded Metal Mesh solutions. Whether a project demands specific material grades, unique mesh patterns (e.g., micro-mesh, heavy-duty), or specialized fabrication, our team collaborates closely with clients from concept to completion. This includes precise cutting to size, forming, welding, and applying a wide range of finishes to meet exact project specifications and aesthetic requirements. We pride ourselves on turning complex engineering challenges into successful outcomes.

Application Case Studies

Real-world applications demonstrate the practical advantages and versatility of Expanded Metal Mesh. Here are a few examples showcasing its utility across different sectors.

Case Study 1: Industrial Walkways and Platforms for Chemical Plant

Challenge: A large chemical processing plant required durable, non-slip, and corrosion-resistant walkways and platforms for its elevated machinery areas. The environment was highly corrosive due to chemical fumes and frequent washdowns. Traditional grating proved too heavy and difficult to install.

Solution: TiKe Metal supplied heavy-duty hot-dip galvanized carbon steel expanded metal mesh (60x30mm LWDxSWD, 4.5mm original thickness) for all elevated walkways and stair treads. The raised pattern provided superior anti-skid properties even when wet or oily.

Result: The client reported significantly improved safety for personnel due to the excellent traction. The galvanized finish ensured robust corrosion resistance, leading to minimal maintenance requirements over several years. The lighter weight of the expanded metal compared to traditional grating also simplified installation and reduced structural load.

Case Study 2: Architectural Facade for Commercial Building

Challenge: An architectural firm sought an aesthetically appealing yet functional facade material for a new commercial office building. The material needed to provide solar shading, allow natural light, and create a modern, high-tech visual identity.

Solution: Customized aluminum expanded metal mesh (LWD 100mm, SWD 40mm, 3.0mm original thickness) with a specialized anodized bronze finish was engineered by TiKe Metal. The large, elongated apertures provided optimal light filtration and thermal regulation.

Result: The facade achieved the desired aesthetic, transforming the building's exterior into a striking visual landmark. Internally, the expanded metal effectively reduced heat gain, contributing to a 15% reduction in cooling costs during peak summer months, and diffused natural light, enhancing occupant comfort and energy efficiency.

Case Study 3: Security Fencing for a Utility Substation

Challenge: A national power utility required a high-security perimeter fence for a critical substation to deter unauthorized access and vandalism. The fence needed to be extremely robust, difficult to cut, and offer clear visibility for surveillance.

Solution: TiKe Metal provided heavy-duty carbon steel expanded metal mesh panels (50x25mm LWDxSWD, 6.0mm original thickness) which were hot-dip galvanized and then powder-coated in a dark green finish. The mesh panels were fabricated into anti-climb designs, integrated with robust steel frames and installed on-site.

Result: The substation's security was significantly enhanced. The monolithic, non-raveling nature of the expanded metal made it extremely difficult to cut or climb, effectively deterring intruders. The clear visibility maintained by the mesh structure also allowed for unobstructed CCTV monitoring, improving the overall security posture of the critical infrastructure.

Trustworthiness and Customer Support

Building trust with B2B clients requires transparency, reliability, and robust support systems. TiKe Metal is committed to providing not just high-quality Expanded Metal Mesh, but also a seamless and dependable customer experience from inquiry to after-sales service.

Frequently Asked Questions (FAQ):

Q1: What are the primary differences between standard (raised) and flattened expanded metal?

A1: Standard (raised) expanded metal has angular strands and an uneven surface, offering superior anti-skid properties and structural rigidity. Flattened expanded metal is cold-rolled after expansion, resulting in a smooth, flat surface with reduced overall thickness. While losing some anti-skid characteristics, it offers a more uniform appearance and easier handling for certain applications.

Q2: How is the open area percentage calculated and why is it important?

A2: The open area percentage is the ratio of the void space to the total area of the mesh. It is crucial as it determines the permeability to light, air, liquids, and visibility. While there's no single universal formula, it's typically derived from LWD, SWD, and strand width. Higher open areas mean more light/air passage, while lower open areas provide greater privacy or finer filtration.

Q3: Can expanded metal be cut or fabricated on-site?

A3: While expanded metal can be cut and shaped on-site using appropriate tools, for precision and maintaining structural integrity, it is highly recommended to provide detailed drawings for factory pre-fabrication. TiKe Metal offers comprehensive cutting, forming, and welding services to deliver ready-to-install components.

Lead Time and Fulfillment:

TiKe Metal operates with optimized production schedules to ensure timely delivery. For standard expanded metal mesh products, typical lead times range from 7 to 14 business days, depending on order volume and current production queue. For highly customized solutions or large-scale projects involving secondary fabrication, lead times will be confirmed upon detailed project assessment, usually ranging from 3 to 6 weeks. We prioritize clear communication regarding delivery schedules and provide regular updates on order status. Our efficient logistics network ensures reliable global shipping.

Warranty Commitments:

TiKe Metal stands behind the quality of its expanded metal mesh products. All products are manufactured under strict ISO 9001 certified quality control systems. We offer a standard warranty covering defects in material and workmanship for a period of 5 years from the date of purchase. Specific project warranties for extended durations may be negotiated for large-scale or critical applications, subject to material specification and intended use conditions.

Dedicated Customer Support:

Our team of experienced technical professionals is available to provide comprehensive support throughout your project lifecycle. From initial consultation and material specification to post-delivery assistance, TiKe Metal is your trusted partner. We offer:

- Technical Consultation: Expert advice on mesh selection, material grades, finishes, and design optimization.

- Quotation and Order Management: Efficient processing of inquiries and transparent order tracking.

- After-Sales Service: Prompt assistance for any queries regarding product performance, installation, or maintenance.

Connect with us via our website's contact form, email, or direct phone line for personalized support.

Conclusion

Expanded Metal Mesh is an ingeniously engineered material offering unparalleled advantages in strength, ventilation, aesthetic flexibility, and cost-effectiveness. Its unique manufacturing process, leading to a robust, monolithic structure without waste, underscores its appeal for a diverse range of B2B applications across construction, petrochemical, architectural, and security sectors. As industries continue to seek durable, sustainable, and high-performance solutions, the role of expanded metal mesh is set to expand further. Partnering with a reputable manufacturer like TiKe Metal, with a proven track record in quality, customization, and customer support, ensures that your projects benefit from the full potential of this exceptional material.

References

- American Society for Testing and Materials (ASTM). ASTM F1267 Standard Specification for Metal, Expanded, Steel.

- International Organization for Standardization (ISO). ISO 9001 Quality Management Systems – Requirements.

- Expanded Metal Manufacturers Association (EMMA). Technical Standards for Expanded Metal.

- Construction and Building Materials Journal. (Various issues on sustainable materials and structural applications).

- Journal of Materials Science and Engineering. (Research papers on material properties and manufacturing processes of metal meshes).