1.Mill Finish: the panel or custom fabricated gratingis delivered in its natural finish, having nothing protecting it. This finish is used when a project requires a natural steel color look, taking into account that its aspect is going to become corroded in few days (appearing oxidation in the piece).

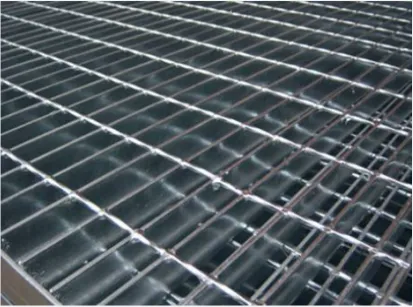

2.Galvanized steel gratings have a glossy look and finish.

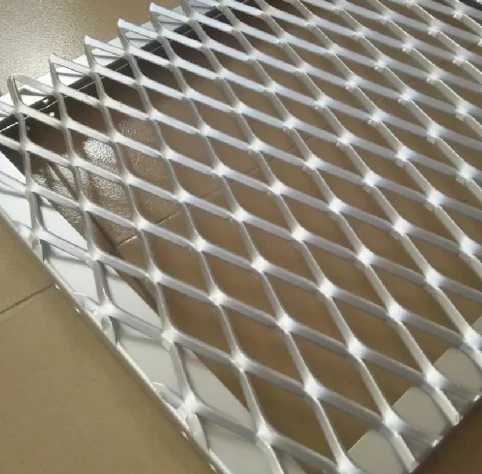

- 3.Powder Coating: this covering application takes place spraying atomized paint particles to steel generating a more efficient paint. This finish is superior to any other in the market. It offers a wide variety of colors.

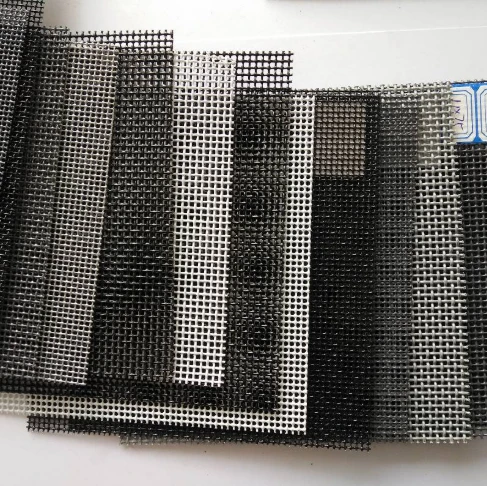

- 4.Popular style:

- It is ideal for industrial purposes because of its advantages. Here are some benefits of galvanized steel gratings:

- 1.Extended Service Life:

- Galvanized steel gratings can last for more than 30 years, even when exposed to the most corrosive environment.

-

- 2.Maintenance Costs:

- Its maintenance costs are relatively low because it doesn't need painting and further maintenance.

-

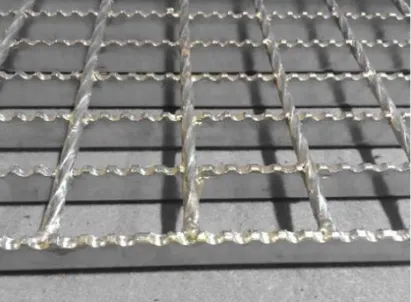

- 3.Scratch Protection:

- Galvanized steel grates are protected from scratches or abrasion when they come into physical contact with machinery or footfall.

-

- 4.Adaptability:

- This grating could be applied to any structure of any shape and size.

|

Verticle Bar Spacing

|

Horizontal Bar Spacing

|

Specification of Supporting Flat Steel (Width X Thickness)

|

|

20 × 3

|

25 × 3

|

32 × 3

|

40 × 3

|

20 × 5

|

25 × 5

|

|

|

30

|

100

|

G203 / 30 / 100

|

G253 / 30 / 100

|

G323 / 30 / 100

|

G403 / 30 / 100

|

G205 / 30 / 100

|

G255 / 30 / 100

|

|

|

50

|

G203 / 30 / 50

|

G253 / 30 / 50

|

G323 / 30 / 50

|

G403 / 30 / 50

|

G205 / 30 / 50

|

G255 / 30 / 50

|

|

|

40

|

100

|

G203 / 40 / 100

|

G253 / 40 / 100

|

G323 / 40 / 100

|

G403 / 40 / 100

|

G205 / 40 / 100

|

G255 / 40 / 100

|

|

|

50

|

G203 / 40 / 50

|

G253 / 40 / 50

|

G323 / 40 / 50

|

G403 / 40 / 50

|

G205 / 40 / 50

|

G255 / 40 / 50

|

|

|

60

|

50

|

-

|

G253 / 60 / 50

|

G253 / 60 / 50

|

G403 / 60 / 50

|

G205 / 60 / 50

|

G255 / 60 / 50

|

|

|

Verticle Bar Spacing

|

Horizontal Bar Spacing

|

Specification of Supporting Flat Steel (Width X Thickness)

|

|

32 × 5

|

40 × 5

|

45 × 5

|

50 × 5

|

55 × 5

|

60 × 5

|

|

|

30

|

100

|

G325 / 30 / 100

|

G405 / 30 / 100

|

G455 / 30 / 100

|

G505 / 30 / 100

|

G555 / 30 / 100

|

G605 / 30 / 100

|

|

|

50

|

G325 / 30 / 50

|

G405 / 30 / 50

|

G455 / 30 / 50

|

G505 / 30 / 50

|

G555 / 30 / 50

|

G605 / 30 / 50

|

|

|

40

|

100

|

G325 / 40 / 100

|

G405 / 40 / 100

|

G455 / 40 / 100

|

G505 / 40 / 100

|

G555 / 40 / 100

|

G605 / 40 / 100

|

|

|

50

|

G325 / 40 / 50

|

G405 / 40 / 50

|

G455 / 40 / 50

|

G505 / 40 / 50

|

G555 / 40 / 50

|

G605 / 40 / 50

|

|

|

60

|

50

|

G325 / 60 / 50

|

G405 / 60 / 50

|

G455 / 60 / 50

|

G505 / 60 / 50

|

G555 / 60 / 50

|

G605 / 60 / 50

|

|

Industrial Flooring /Walkways /Bridge Decks/Trenches/Steel Mills/Warehouses/ Chemical Plants/Water Treatment Plants/Power Plants/Oil Refineries /Agricultural Facilities