Understanding the intricacies of welded wire mesh pricing is essential for anyone involved in construction, agriculture, or any industry that utilizes this versatile material. With years of experience in SEO and a deep understanding of industry trends, this article provides an unparalleled, authoritative exploration of what influences welded wire mesh prices and how to make informed purchasing decisions.

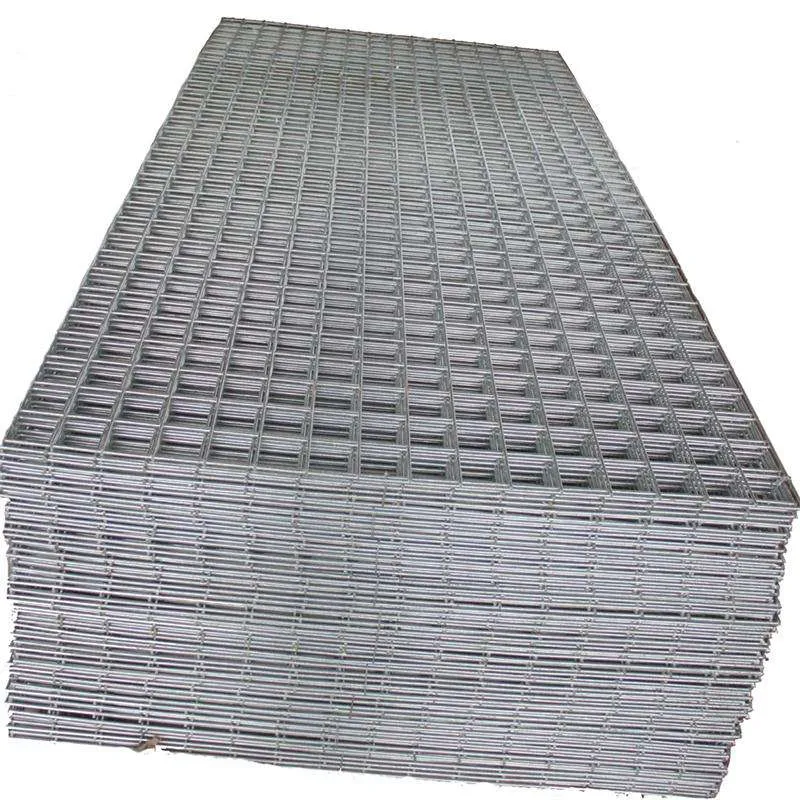

Welded wire mesh, known for its durability and adaptability, is indispensable in various applications ranging from concrete reinforcement to animal fencing. However,

the price of welded wire mesh can vary significantly based on several influencing factors. Understanding these factors is crucial for both buyers and sellers aiming to optimize their spending and maximize returns.

Material Costs The primary determinant of welded wire mesh price is the material used. Typically, welded wire mesh is made from steel, but variations such as galvanized or PVC-coated options can affect the price. Galvanized wire mesh, for instance, is treated with a layer of zinc to prevent rust and corrosion, making it more expensive but also more durable. PVC-coated mesh offers additional protection and aesthetic appeal, impacting the cost further.

Wire Diameter and Aperture Size The thickness of the wire and the size of the openings (apertures) in the mesh are critical technical specifications that affect price. Thicker wires provide greater strength and are more costly to produce. Similarly, a smaller aperture requires more wire per square meter of mesh, elevating manufacturing costs and, consequently, the market price.

Manufacturing Processes Advanced manufacturing technologies and processes lead to higher quality but can also increase costs. Automated and precision welding techniques ensure uniformity and strength in the mesh, but the investment in these technologies by manufacturers is reflected in higher prices.

welded wire mesh price

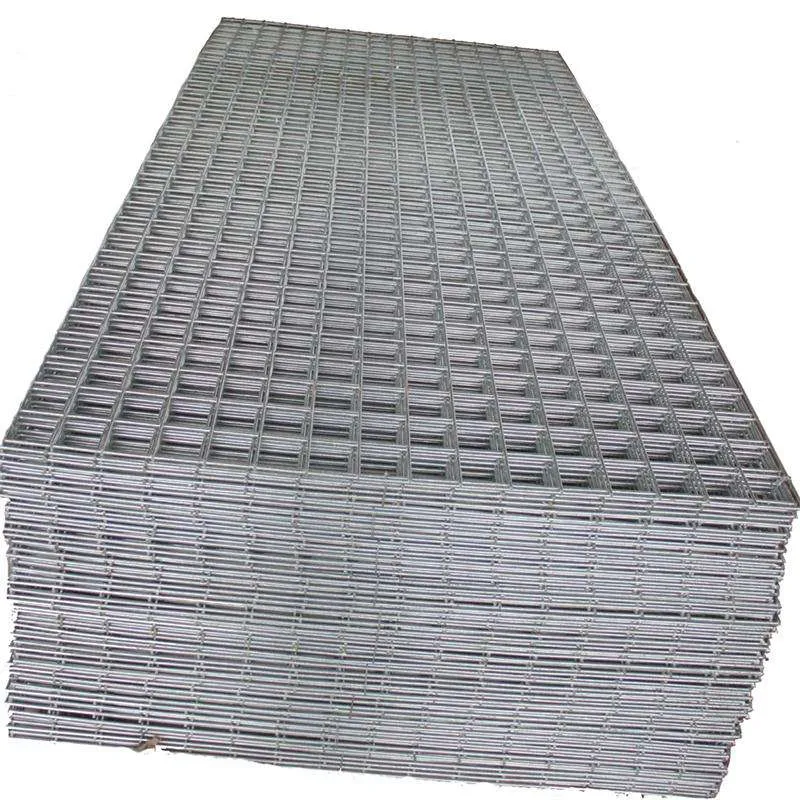

Economy of Scale and Order Quantity Purchasing in bulk can significantly reduce the cost per unit of welded wire mesh. Manufacturers often offer discounts for large orders due to decreased production costs and assured sales. Customers able to store and use large quantities can benefit from these economies of scale, reducing overall project costs.

Market Demand and Supply Fluctuations Just like any commodity, the price of welded wire mesh is heavily influenced by market dynamics of demand and supply. An increase in construction activities or agricultural projects can drive up demand, influencing prices positively. Conversely, an oversupply in the market can lead to reduced prices.

Geographical Location The location of the buyer relative to the manufacturer or distributor significantly impacts the price. Factors such as shipping costs, local taxes, and tariffs must be considered. Importing welded wire mesh from overseas can incur additional costs, such as customs duties, which must be factored into the total expenditure.

Vendor Reputation and Certification Engaging with reputable suppliers often assures better quality and compliance with industry standards. Certified vendors may offer higher-priced products, but the assurance of quality and the potential for long-term savings through reduced maintenance and replacement costs can outweigh the initial investment.

Conclusion Investing in welded wire mesh requires a comprehensive understanding of the factors that influence its pricing. Buyers should assess their specific needs, prioritize quality and durability, and analyze market conditions to make informed decisions. Engaging with trusted vendors who offer transparent pricing and expert advice can lead to substantial cost savings and project success. As a seasoned Google SEO specialist, leveraging these insights not only enhances content relevance and authority but also guides consumers towards making decisions that optimize both quality and cost.