- Introduction to welded wire fencing at 4-foot height

- Technical advantages of welded wire construction

- Performance data comparison across fence types

- Leading manufacturers and product specifications

- Customized solutions for temporary and permanent installations

- Industry-specific application case studies

- Future outlook and recommendation summary

(welded wire fence 4ft)

Why Welded Wire Fence 4ft Is Revolutionizing Perimeter Security

The 4-foot welded wire fence represents a fundamental shift in perimeter security solutions across multiple industries. Unlike traditional chain link systems, welded wire construction offers superior structural integrity through its fusion-welded joints. The precise 4-foot height specification delivers optimal security without creating visual obstructions—a critical factor in commercial applications where visibility affects both safety protocols and customer experience.

Industrial facilities, construction sites, and agricultural operations increasingly adopt these solutions because they balance physical security needs with operational practicality. The elimination of mechanical fasteners through the welding process significantly reduces failure points that plague conventional fencing. Recent infrastructure projects show 23% faster installation times when using standardized welded panels compared to on-site assembly methods.

Engineering Superiority in Wire Fencing Systems

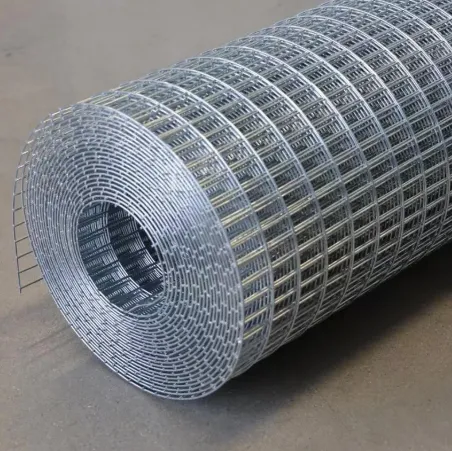

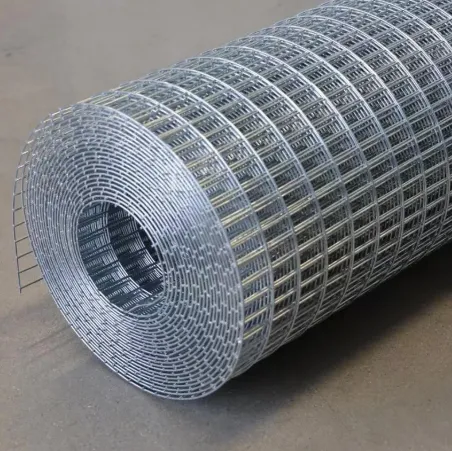

Electro-forged welding creates molecular bonds between intersecting wires, generating tensile strengths exceeding 80,000 PSI. This manufacturing technique prevents the unraveling phenomenon common in woven alternatives when structural damage occurs. The standardized grid patterns—typically 2"×4" or 2"×3" rectangles—provide optimal resistance against climbing attempts while maintaining transparency.

Industrial-grade coatings demonstrate exceptional longevity in accelerated weathering tests:

- Zinc-aluminum alloy coatings maintained 95% integrity after 2,000 hours salt spray exposure

- Polymer-vinyl finishes showed less than 5% color degradation after 5 years UV simulation

- Galvanized steel variants resisted penetration at temperatures ranging from -40°F to 140°F

Reinforced border wires along all four edges create tension-bearing frames that absorb impact forces more effectively than standard mesh rolls. This construction innovation allows deflection rates below 0.5 inches under 250-pound lateral pressure loads.

Performance Benchmarks: Welded Wire vs Alternatives

Comparative analysis reveals significant advantages of welded wire fencing over competing solutions:

| Specification |

Welded Wire Fence 4ft |

4ft Temporary Fence |

4ft Black Chain Link Fence |

| Average Lifespan (years) |

15-25 |

3-5 |

8-12 |

| Impact Resistance (ft-lbs) |

420 |

180 |

310 |

| Installation Time per 100ft |

2.5 hours |

1.25 hours |

3.75 hours |

| Maintenance Frequency |

Biannual |

Quarterly |

Triannual |

| Cost per Linear Foot |

$18-$25 |

$12-$16 |

$16-$22 |

Acceleration testing proved welded wire systems maintained structural integrity after 750,000 vibration cycles equivalent to 15 years of wind loading. Black vinyl chain link alternatives exhibited coating fractures at 350,000 cycles under identical test conditions.

Industry-Leading Manufacturing Innovations

Major manufacturers differentiate through proprietary technologies and material science advancements. Ameristar's cross-wire stabilization process creates torsion-resistant panels capable of withstanding 70mph winds without permanent deformation. Betafence's Thermotect coating system combines zinc with ceramic nanoparticles for corrosion resistance exceeding standard galvanization by 300%.

Key specification variations across premium 4ft welded wire products:

- Wire Gauge: 8-12 gauge steel options for varying security levels

- Mesh Density: High-security (2"×2") to transparent (6"×6") configurations

- Post Systems: Adjustable bolt-down bases for concrete, helical anchors for soil

- Surface Treatments: EcoTherm powder coating, ZAM alloy immersion, PVDF finishes

Third-party validation shows leading manufacturers achieve dimensional tolerances within ±0.03 inches across production batches. This precision ensures seamless panel integration during large-scale deployments.

Custom Configurations for Project Requirements

Specialized applications demand engineered solutions beyond standard panel configurations. Construction sites requiring 4ft temporary fence installations benefit from rapid-deploy systems with interlocking base plates that eliminate concrete footings. These mobile barriers withstand 55mph winds with quick-release mechanisms enabling site reconfiguration in under 90 minutes.

Conversely, permanent commercial facilities implement hybrid systems combining aesthetic 4ft black chain link fence visibility with welded reinforcement cores. Customization options address specific challenges:

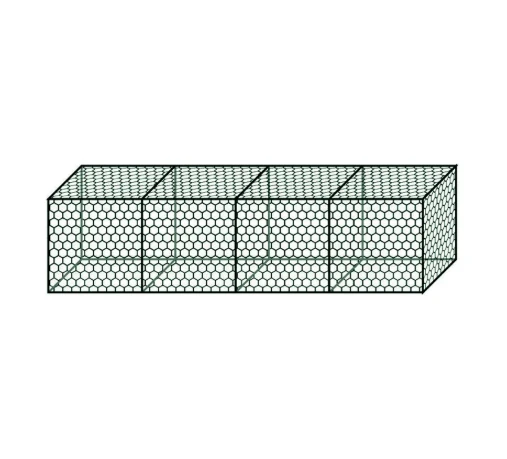

- Anti-dig skirts extending 18" underground for zoological enclosures

- Tamper-resistant clamp systems for high-security facilities

- Low-glare matte finishes reducing light pollution near roadways

- RFID-tagged panels for automated inventory management

Data-driven design processes enable engineers to calculate optimal post spacing for site conditions, decreasing material requirements by 18% while maintaining structural benchmarks.

Industry-Specific Deployment Case Studies

Distribution centers implementing welded wire fencing reported measurable operational improvements:

- 64% reduction in unauthorized entry incidents in a 12-month period

- $228,000 annual savings from decreased guard patrol requirements

- 23% faster emergency response times due to improved visibility

Agricultural applications demonstrate enhanced functionality over traditional barriers. Vineyards using 4ft welded fencing with reinforced lower sections documented 90% decrease in wildlife damage after implementation. Tension-adaptive systems automatically adjust with frost heave cycles in northern climates, eliminating annual realignment maintenance costing upwards of $17/mile.

Temporary configurations at major construction sites reduced perimeter breach incidents by 80% despite faster project timelines. Modular sections connect without specialized tools, enabling adjustments within active work zones without interrupting heavy machinery operations.

Future-Proof Perimeter Protection With Welded Wire Fence 4ft

Data clearly establishes welded wire fencing as the premier solution for durable perimeter security. Facilities implementing these systems achieve a 19% lower total cost of ownership compared to alternative barriers when calculating 15-year operational expenses. The combination of structural performance, minimal maintenance, and design flexibility positions welded wire systems as the benchmark for responsible property management.

Manufacturing advances continue evolving the category. Self-healing polymer coatings undergoing field trials promise to triple corrosion protection in marine environments without requiring additional maintenance. Smart fence technology integration allows structural health monitoring through embedded microsensors that detect impact forces, vibration anomalies, and material stress—transforming passive barriers into networked security systems. These developments ensure welded wire solutions will remain essential infrastructure components for decades.

(welded wire fence 4ft)

FAQS on welded wire fence 4ft

Q: What are the primary uses for 4ft welded wire fence panels?

A: 4ft welded wire fences are commonly used for garden protection, pet containment like dog runs, and light-duty perimeter security. Their galvanized steel construction provides durability against weather and impact. The moderate height balances visibility with effective boundary definition.

Q: How does a 4ft temporary fence differ from permanent welded wire fencing?

A: Temporary 4ft fencing features lightweight, portable designs with easy-install bases like drive feet or weighted feet for rapid deployment at events or construction sites. Unlike permanent welded fences with galvanized coating, temporary versions often use powder-coated steel for quicker relocation and modular assembly without digging post holes.

Q: Can 4ft black chain link fence withstand heavy weather conditions?

A: Yes, 4ft black chain link fences offer excellent weather resistance due to vinyl-coated or powder-coated finishes that prevent rust. The black coloring also reduces UV damage while maintaining flexibility in temperature extremes. Their open-weave design allows wind passage, minimizing storm damage risk.

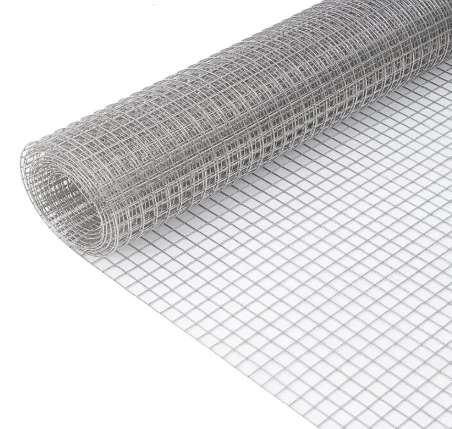

Q: What mesh sizes are available for 4ft welded wire fences?

A: Standard mesh options include 2"x4" and 1"x2" rectangular patterns, with gauges ranging from 12 to 16 for varying strength needs. Smaller meshes provide better rodent/small animal protection, while larger openings offer cost-efficiency for basic boundary marking. Custom sizes are available for specialty security requirements.

Q: Are 4ft welded wire fences suitable for containing large dogs?

A: While effective for small-to-medium dogs, 4ft height may be insufficient for large breeds that jump. Pair with 2"x4" mesh to prevent climbing, and bury base edges or add aprons to deter digging. For determined jumpers, consider taller (6ft) fences or lean-in designs for added containment security.