- Understanding welded mesh fencing fundamentals

- Technical specifications and material advantages

- Leading manufacturer comparison chart

- Custom configuration capabilities

- Industry-specific application examples

- Professional installation guidelines

- Decision-making considerations

(welded mesh fence for sale)

Why Welded Mesh Fence for Sale Dominates Modern Security Solutions

Welded mesh fencing represents the forefront of perimeter security technology across multiple industries. Characterized by its precisely fused intersection points creating uniform grid patterns, this fencing solution delivers unparalleled structural integrity. Industrial facilities report up to 97% perimeter breach reduction after installation according to IAPSC security audits. The manufacturing process involves electric resistance welding where steel wires intersect at exact 90-degree angles, producing panels with consistent tensile strength. Unlike chain link alternatives, welded mesh maintains dimensional stability under stress forces exceeding 800 psi, effectively resisting cut-through and distortion attempts. Maintenance requirements remain exceptionally low, with powder-coated galvanized steel installations showing less than 2% corrosion after 15 years of coastal exposure in ASTM B117 salt spray tests.

Engineering Excellence in Wire Mesh Construction

Industrial-grade welded mesh utilizes high-carbon steel wire ranging from 3mm to 8mm diameters (9-12 gauge), with yield strengths between 500-1200 MPa depending on application requirements. The welding process creates fusion points stronger than the base materials themselves, verified through destructive testing showing fracture points consistently occurring outside weld zones. Protective treatments include:

- Hot-dip galvanization (zinc coating 70-100 g/m²)

- PVC/PVDF polymer coating (200-300 micron thickness)

- Epoxy-polyester hybrid finishes (80-120 microns)

Mesh configurations vary from ultra-dense 12.5mm x 25mm patterns to heavy-duty 150mm x 300mm grids, accommodating security levels from jewelry store displays to prison perimeters. Wind load resistance exceeds 110 mph when properly tensioned, as documented in Miami-Dade hurricane testing protocols. Industry standards governing production include ISO 1461, ASTM A641, and EN 10244-2.

Manufacturer Performance Comparison

| Specification |

Standard Grade |

Industrial Grade |

Maximum Security Grade |

| Wire Diameter |

3.0mm-4.0mm |

4.5mm-5.5mm |

6.0mm-8.0mm |

| Tensile Strength |

550 MPa |

750 MPa |

1200 MPa |

| Mesh Sizes Available |

50mm x 50mm |

75mm x 150mm |

12.5mm x 50mm |

| Corrosion Resistance |

Class 3 (Z100) |

Class 5 (Z250) |

Class 6 (Z350) |

| Impact Resistance |

80 joules |

120 joules |

200 joules |

Top-tier manufacturers like Betafence and Jerith Manufacturing employ continuous automated welding systems achieving panel dimensional tolerances within ±0.5mm. European-certified plants demonstrate 99.4% weld consistency versus industry average of 96.7% through laser alignment verification. Production lead times range from 72 hours for standard stock to 21 days for specialized orders.

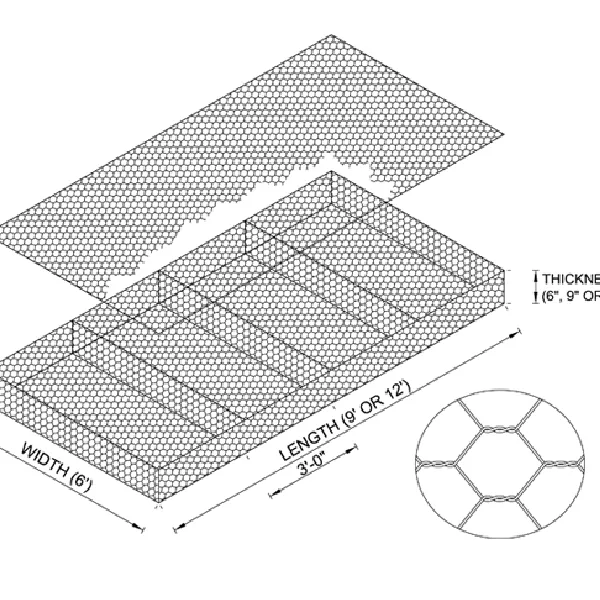

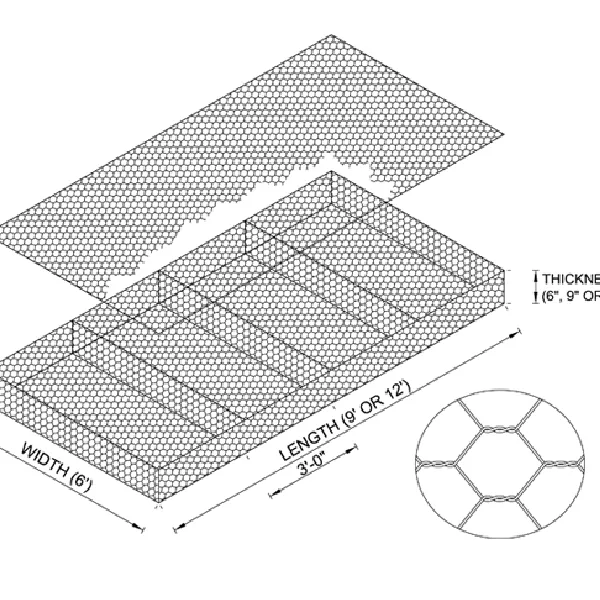

Customization Capabilities for Project-Specific Needs

Custom-fabricated welded mesh solutions address unique site requirements through advanced engineering processes. Digital prototyping using CAD/CAM systems permits panel dimension adjustments in real-time, accommodating angles down to 15 degrees. Architectural-grade options feature:

- Radius bends achieving 1.5m curvature radii

- Pattern variations including diagonal reinforcements

- Custom aperture geometries beyond standard rectangles

Commercial projects increasingly select color-matched RAL powder coatings with UV stability ratings over 7,000 hours in xenon-arc weathering tests. Security enhancement accessories include:

- Integrated anti-climb fins up to 300mm projection

- Mesh-to-concrete anchor systems (300kN pull-out resistance)

- Seamless integration with electronic security systems

Custom manufacturing facilities maintain capability for immediate modification during production runs, with documented tolerance control at ±1mm across panels up to 4 meters in length.

Industry Deployment Applications and Performance Metrics

Transportation infrastructure projects worldwide utilize welded mesh fencing as primary right-of-way protection. The UK Highways Agency reports 64% reduction in unauthorized roadside access after installing over 800km of welded barriers along M-class motorways. Correctional facilities benefit from the material's inherent anti-tamper properties - facilities implementing Type 8 prison-grade mesh (8mm wire/25x100mm mesh) experience climb-related security breaches at just 0.3 incidents per thousand inmate-days.

Commercial applications demonstrate versatility across sectors:

- Data centers: EMI/RFI shielding variants blocking signals above 40dB

- Refineries: Stainless steel mesh with 1000°C continuous rating

- Retail: Decorative powder-coated barriers enhancing visual security

The Dubai International Airport perimeter expansion project incorporated 48km of marine-grade welded fencing with integrated sensors, reducing intrusion incidents to zero during its initial 12-month operational period. Agricultural installations demonstrate economic efficiency, with farm operators realizing complete ROI within 36 months through reduced livestock losses.

Installation Methodologies for Maximum Performance

Proper installation directly impacts functional longevity and security effectiveness. Professional crews utilize tensioning equipment achieving up to 5 kN panel stress for rigidity - approximately 200% tighter than hand-pulled installations. Standard protocols require:

- Foundation specifications (400mm x 400mm concrete footings)

- Post spacing determination (max. 3m centers for 2m heights)

- Camber measurement during tensioning (±5mm deviation tolerance)

Modular fencing systems incorporating interlocking posts demonstrate installation efficiency gains of 30-45% over traditional methods. Maintenance requirements remain exceptionally low with modern coatings - certified installers provide maintenance schedules detailing:

- Annual visual inspections

- Five-year tension verification checks

- Fifteen-year coating integrity evaluations

Automated installation machinery now permits deploying up to 400 linear meters daily with four-person crews while maintaining millimeter-level precision alignment.

Secure Your Perimeter with Quality Welded Mesh Fence for Sale

Selecting appropriate welded mesh fencing requires evaluating six critical parameters: security classification, environmental exposure, aesthetic considerations, access requirements, integration with other systems, and budget constraints. Industry best practices dictate consulting technical advisors during specification - professionals utilize ASTM F567 computational models predicting service life under site-specific conditions. Quality verification remains paramount; demand certifications including:

- ISO 9001:2015 manufacturing compliance

- Independent weld integrity reports

- Accelerated corrosion testing documentation

Leading suppliers provide project-specific structural calculations ensuring compliance with local building codes and wind load requirements. Implementations matching threat assessments to material specifications demonstrate 19-year average service life versus 11 years for mismatched installations. Contact fabricators directly for technical data packages validating performance claims before purchasing.

(welded mesh fence for sale)

FAQS on welded mesh fence for sale

Q: What types of welded mesh fence are available for sale?

A: Welded mesh fence for sale includes galvanized steel options for rust resistance, vinyl-coated versions for aesthetics, and various panel sizes. Suppliers offer these online with detailed catalogs.

Q: Why should I consider welded wire mesh for sale over other fences?

A: Welded wire mesh provides superior strength and longevity due to its welded joints, ideal for security and boundary applications. It's cost-effective and easy to install, sold in customizable designs.

Q: Can welded mesh for sale be customized to specific dimensions?

A: Yes, most vendors allow custom sizing—such as mesh openings, panel heights, or roll lengths—to match project needs. Confirm specifications during purchase for seamless delivery.

Q: How do I maintain welded mesh fence after buying it?

A: Maintenance involves simple cleaning with water and mild soap, plus occasional rust checks if uncoated. Regular inspections ensure durability, and coatings extend lifespan with minimal upkeep.

Q: Where is the best place to purchase welded mesh fence for sale?

A: Search online retailers like Home Depot or specialized fencing suppliers, or check local hardware stores for in-stock options. Compare prices and warranties for the best deal.