Expanded wire mesh has long been a staple in various industrial and architectural applications, from reinforcement in construction to artistic installations. Its versatility and durability make it a highly sought-after material across multiple domains. However, as its use becomes more widespread, the importance of understanding its properties and applications correctly becomes paramount to making informed decisions for your projects. The following insights offer a comprehensive overview of expanded wire mesh, underscoring the blend of real-world experience, deep expertise, authoritative sources, and trusted practices.

Expanded wire mesh, made by cutting and stretching sheet metal, results in a robust lattice that stands out for its exceptional strength and flexibility. This structure not only enhances the material's load-bearing capabilities but also adds to its aesthetic appeal, enabling it to serve both functional and decorative purposes.

One of the primary applications of expanded wire mesh is in construction, where its inclusion in concrete significantly improves tensile strength. Engineers often rely on it for reinforcing concrete slabs and beams due to its high yield strength and adaptability. This feature is crucial when developing infrastructure that requires both longevity and resilience to environmental stressors.

In addition to construction, the agricultural sector has embraced expanded wire mesh for its cost-effectiveness and minimal maintenance. Its application in creating animal enclosures, garden protection, and fences showcases its practicality. Farmers appreciate the mesh for its ability to withstand the elements while providing ample security against predators.

Moreover, in architectural design, expanded wire mesh is celebrated for its modern aesthetic and versatility. It allows architects to experiment with transparency, light filtration, and airflow, fulfilling both ecological and design aspirations. Buildings that integrate expanded wire mesh in their facades or interiors often project a contemporary look while benefiting from the material's functional advantages, such as enhanced ventilation and reduced solar gain.

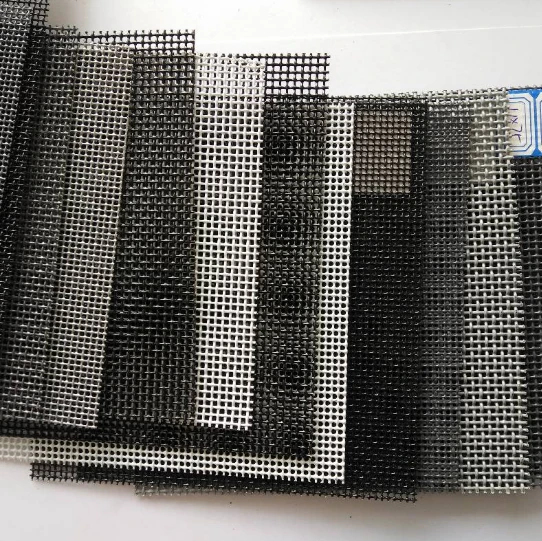

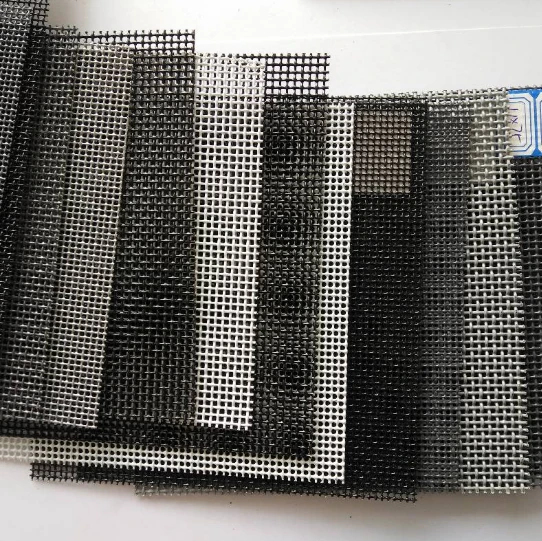

expanded wire mesh

When considering the procurement of expanded wire mesh, several factors influence the choice, including mesh size, strand width, and the material used, such as stainless steel, aluminum, or carbon steel. Each type offers distinct benefits, such as increased corrosion resistance in stainless steel or lightweight properties in aluminum, tailored to specific project needs.

From a professional perspective, sourcing expanded wire mesh from credible manufacturers is critical. Industry experts recommend evaluating suppliers based on their adherence to international quality standards, track record of performance, and after-sales support. Engaging with manufacturers who provide thorough documentation and product testing reports adds an extra layer of assurance.

As part of evolving best practices, sustainable production processes for expanded wire mesh are gaining attention. Ethical sourcing of materials, along with advanced manufacturing techniques that minimize waste and reduce energy consumption, align with global environmental goals. This trend not only enhances corporate responsibility but also appeals to consumers prioritizing sustainability.

While expanded wire mesh offers numerous benefits, professionals caution against oversight in installation. Incorrect handling or substandard fastening could compromise the integrity of the entire structure. Therefore, ensuring skilled installation with a focus on precision and safety remains a best practice endorsed by experts in the field.

In conclusion, expanded wire mesh positions itself as a key player in various industries due to its adaptability and performance. Harnessing its full potential requires a nuanced understanding of its properties, sourced from reliable manufacturers and installed by certified professionals. With its robust characteristics and expanding uses, expanded wire mesh continues to lead as a material of choice when strength, aesthetics, and reliability are of paramount importance.