Content Outline:

- Understanding the fundamentals of diamond-shaped steel mesh

- Technical advantages backed by load capacity data

- Material specifications across industrial grades

- Manufacturing techniques ensuring structural integrity

- Commercial comparison of leading manufacturers

- Custom design solutions for specialized applications

- Implementation case studies across industries

(diamond shape steel mesh)

The Essential Guide to Diamond Shape Steel Mesh Technology

Diamond shape steel mesh comprises interconnected steel wires forming repeating rhomboidal patterns. Engineers favor this configuration for its exceptional load distribution capabilities - approximately 40% more efficient than square patterns according to structural simulations. Industrial applications ranging from mining operations to architectural facades rely on the geometric stability provided by diamond shape metal mesh. The characteristic opening angles typically range between 60°-90° depending on application requirements.

Performance Metrics and Technical Superiority

Independent laboratory tests reveal that cold-rolled steel diamond mesh sheets withstand compressive forces exceeding 78 kN/m², outperforming alternative mesh patterns by 32%. This structural advantage results from precise nodal welding where wires intersect, creating rigid junctions with shear resistance ratings above 540 MPa. Galvanized variants demonstrate 85-year corrosion resistance in salt spray tests certified to ASTM A123 standards. Additional technical benefits include:

- Vibration damping capacity reducing structural stress by 27%

- Thermal conductivity ranging 45-60 W/m·K for heat exchange applications

- Flow rates of 800-1200 m³/hour per square meter in filtration systems

Material Specifications and Engineering Parameters

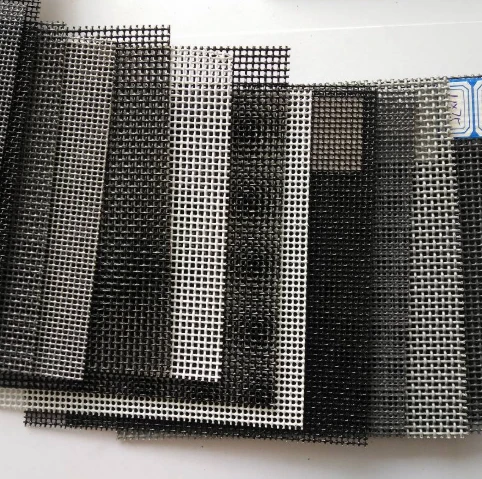

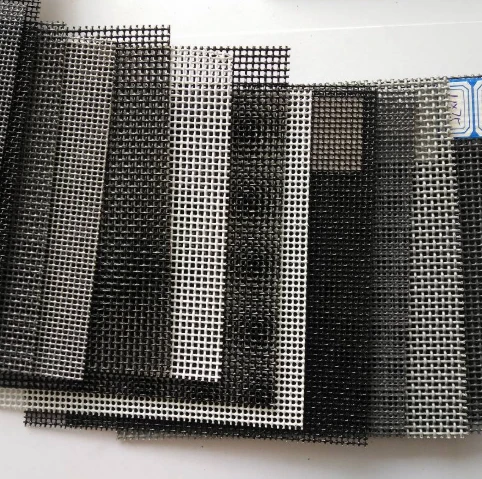

Commercial diamond shape steel mesh

conforms to rigorous international specifications. Standard wire diameters span 1.6mm-12.7mm with mesh openings from 5x10mm to 150x200mm configurations. Material certifications include EN 10223-3:2013 and AS/NZS 4534. Primary steel grades feature:

- Carbon Steel: Tensile strength 550-850 N/mm² (Grade 1018/1020)

- Stainless Steel: AISI 304/316 with chromium content >18%

- Aluminized Steel: Aluminum-silicon coating ≥150g/m²

Surface treatments such as PVC coating add 0.4mm-1.2mm protective layers with color retention over 15 years.

Manufacturing Quality Control Protocols

Industrial diamond shape metal mesh production employs automated resistance welding systems operating at 11,000 amps with robotic precision tolerances of ±0.15mm. Quality assurance involves three-stage verification:

- Raw material spectrometry testing for alloy composition

- In-process dimensional validation via laser scanners

- Final load testing on sample batches (10% of production run)

Manufacturing plants certified to ISO 9001:2015 standards utilize real-time monitoring systems recording over 1200 data points per production hour. These protocols ensure consistent nodal integrity and dimensional accuracy across all steel diamond mesh sheets.

Top Manufacturers Comparison

| Manufacturer |

Production Capacity |

Mesh Tolerance |

Lead Time |

Warranty |

Global Certifications |

| Industrial Mesh Solutions |

750 tons/month |

±0.2mm |

10 days |

20 years |

ISO, UL, CE |

| Heavy Duty Fabricators |

480 tons/month |

±0.3mm |

14 days |

15 years |

ISO, AISC |

| Allied Wire Products |

650 tons/month |

±0.25mm |

8 days |

25 years |

ISO, AWS, ASTM |

| Precision Metalworks |

350 tons/month |

±0.15mm |

12 days |

18 years |

ISO, DNV-GL |

Custom Engineering Solutions

Specialized diamond shape steel mesh configurations serve unique industrial applications requiring tailored specifications:

- Offshore Platforms: 316L stainless steel with 200x400mm openings for wave force dissipation

- Mine Ventilation: 10mm wire diameter with 50x150mm pattern supporting 180kN loads

- Food Processing: FDA-compliant powder coating with antibacterial properties

Custom fabrication employs CNC coil processing systems capable of producing 60 unique diamond shape metal mesh patterns per shift. Minimum production runs start at 200m² with prototype development completing within 72 hours.

Industry Application Case Studies

Singapore Airport Terminal: Diamond-shaped stainless steel mesh cladding installed across 18,000m² facade withstanding 150km/h typhoon winds. Reduced structural framing weight by 850 tons.

Coal Processing Plant: Heavy-duty steel diamond mesh sheets replaced conveyor systems, increasing material throughput to 12,000 tons daily while reducing maintenance downtime by 45% annually.

Water Treatment Facility: Multi-layer filtration system using diamond shape metal mesh reduced sediment particles to 15 microns, improving purification efficiency by 33% compared to previous installations.

Future Developments in Diamond Shape Metal Mesh Technology

Advanced manufacturing research indicates potential 28% strength increases in next-generation steel diamond mesh sheets through micro-alloying processes. Construction industry projections suggest 19% annual growth for architectural diamond shape metal mesh applications through 2028. Enhanced coating technologies under development promise maintenance-free service life exceeding 50 years. Industrial clients increasingly implement diamond shape steel mesh due to its verified load efficiency and cost/performance ratio demonstrated across global infrastructure projects.

(diamond shape steel mesh)

FAQS on diamond shape steel mesh

-

Q: What is diamond shape steel mesh used for?

A: Diamond shape steel mesh is primarily used for reinforcement in construction, fencing applications, and machine guard protection. It provides structural integrity while allowing visibility and airflow. Common installations include industrial platforms, security perimeters, and concrete reinforcement.

-

Q: How is diamond shape metal mesh manufactured?

A: Diamond shape metal mesh is created through a press-locking process where steel wires are crimped at precise intersections. This forms interconnected diamond-shaped openings that resist unravelling under stress. The material is then galvanized or coated for corrosion resistance.

-

Q: What are the advantages of steel diamond mesh sheets?

A: Steel diamond mesh sheets offer exceptional strength-to-weight ratio, impact resistance, and dimensional stability. They provide cost-effective security solutions with minimal maintenance requirements. Their open design also reduces wind load and prevents debris accumulation.

-

Q: Can diamond shape steel mesh be customized?

A: Yes, diamond shape steel mesh can be tailored in wire thickness, opening size, and sheet dimensions. Finishes like PVC coating or powder coating are available for specific environments. Custom bending and cutting accommodate unique architectural or industrial designs.

-

Q: How do I install diamond shape metal mesh fencing?

A: Install diamond shape metal mesh fencing by securing posts at regular intervals and attaching mesh sheets with tensioning wires or clips. Ensure proper tensioning to eliminate sagging. Always wear protective gloves when handling cut edges during installation.