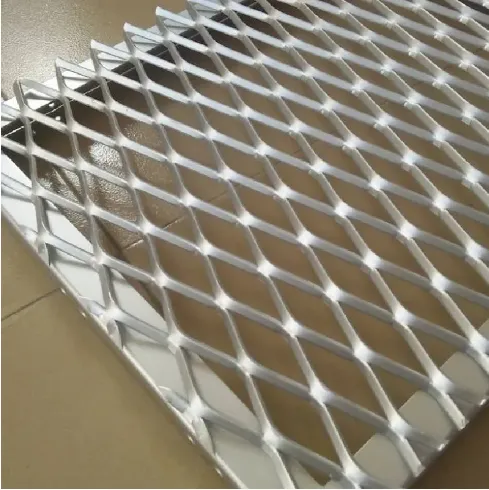

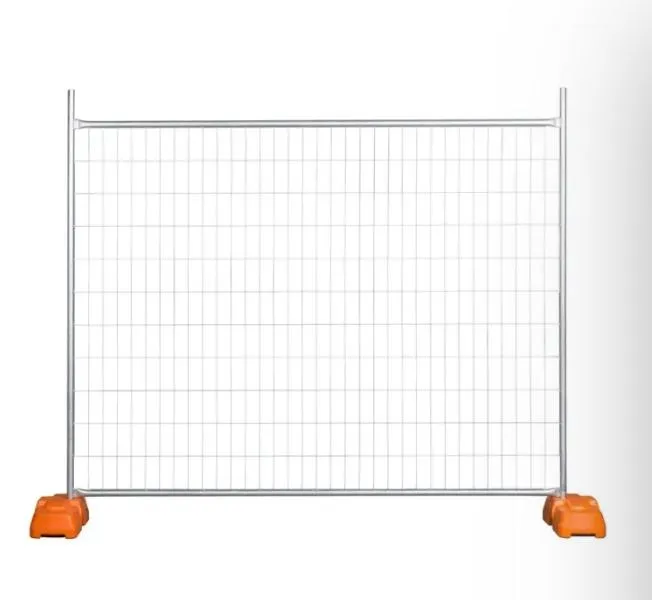

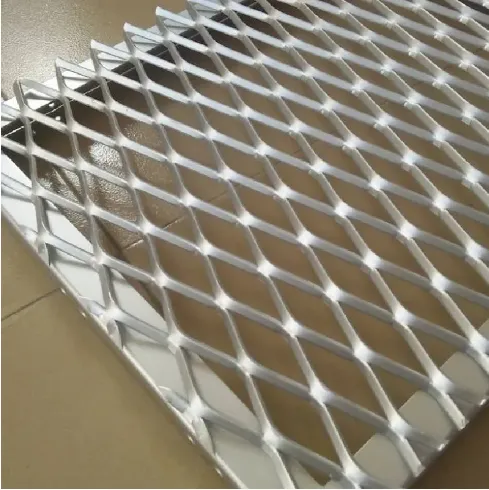

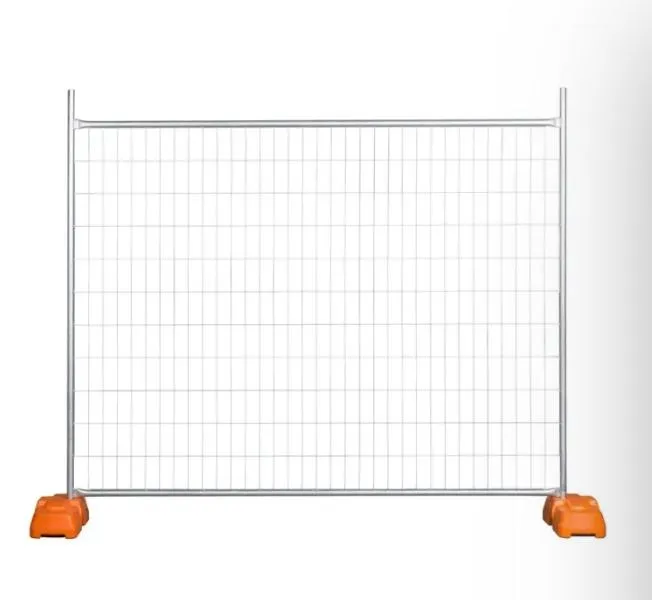

Structural steel grating stands as a pivotal component in modern construction and industrial settings, offering versatility, durability, and strength. This grating consists of an assembly of steel bars that create a robust and open-grid surface. Its applications range from walkways and platforms to stair treads and trench covers, all benefiting from the inherent characteristics of steel.

Experience with structural steel grating reveals its vital importance in environments that demand resilience and load-bearing capacity. For instance, in manufacturing plants where large machinery and constant traffic are prevalent, steel grating provides the necessary support without compromising safety. The open design not only facilitates quick drainage of liquids but also ensures the circulation of air and light, creating safer and more efficient workspaces.

From an expertise standpoint, understanding the specific types of steel grating is crucial for selecting the right product. Standard options include welded, press-locked,

and swaged grating. Welded grating features a sturdy one-piece construction, created by welding cross bars to bearing bars under pressure and heat, ensuring a high-strength joint. Press-locked grating, on the other hand, offers a smooth surface as it utilizes mechanical interlocking rather than welding. This option is often chosen for aesthetic reasons in architectural applications. Lastly, swaged grating is characterized by its lightweight properties and flexibility, suitable for installations that require ease of handling and installation.

Authoritativeness in the structural steel grating industry is rooted in adherence to rigorous standards and specifications, such as those outlined by the American National Standards Institute (ANSI) or the European Standard (EN). These standards ensure products meet performance criteria related to safety, load capacity, and durability. Companies specializing in steel grating often employ engineers and material scientists to oversee production, ensuring their offerings are both innovative and compliant with regulations.

structural steel grating

Trustworthiness is closely tied to the reputation and integrity of manufacturers and suppliers. A reliable producer of structural steel grating will provide transparency in their production process, from raw material sourcing to final quality checks. This transparency is critical in fostering customer trust. Certifications and memberships, such as those from the International Organization for Standardization (ISO), further establish a company’s commitment to quality and customer satisfaction.

Furthermore, advancements in technology have enhanced the design and production of structural steel grating. The use of computer-aided design (CAD) allows for customized solutions that perfectly fit specific project requirements, optimizing both functionality and cost-effectiveness. This level of precision ensures that the grating performs effectively in its intended application, whether in a high-traffic industrial environment or as part of an architectural feature.

In conclusion, structural steel grating is much more than a simple construction material. Its application requires a deep understanding of both its physical properties and the specific needs of the project at hand. Partnering with a reputable manufacturer that demonstrates experience, expertise, authoritativeness, and trustworthiness will result in the successful implementation of durable and reliable steel grating solutions, tailored to meet the diverse demands of modern infrastructure and industry.