In the rapidly evolving landscape of digital design and manufacturing, the concept of a flattened mesh plays a pivotal role in streamlining processes from prototyping to production. A flattened mesh represents a 3D model's surface that has been 'unfolded' or 'flattened' into a 2D plane. This transformation is crucial for various applications, ranging from textiles to metalwork, and can significantly enhance efficiency in manufacturing and prototyping.

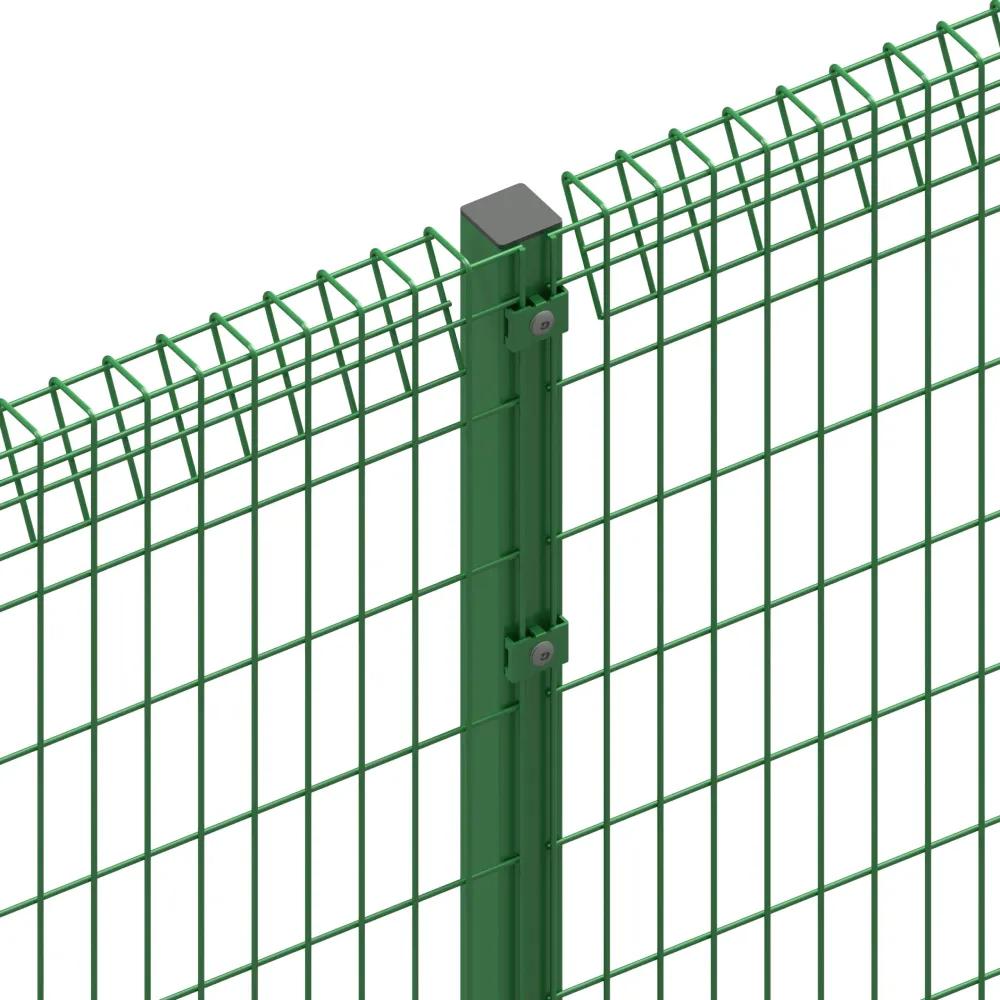

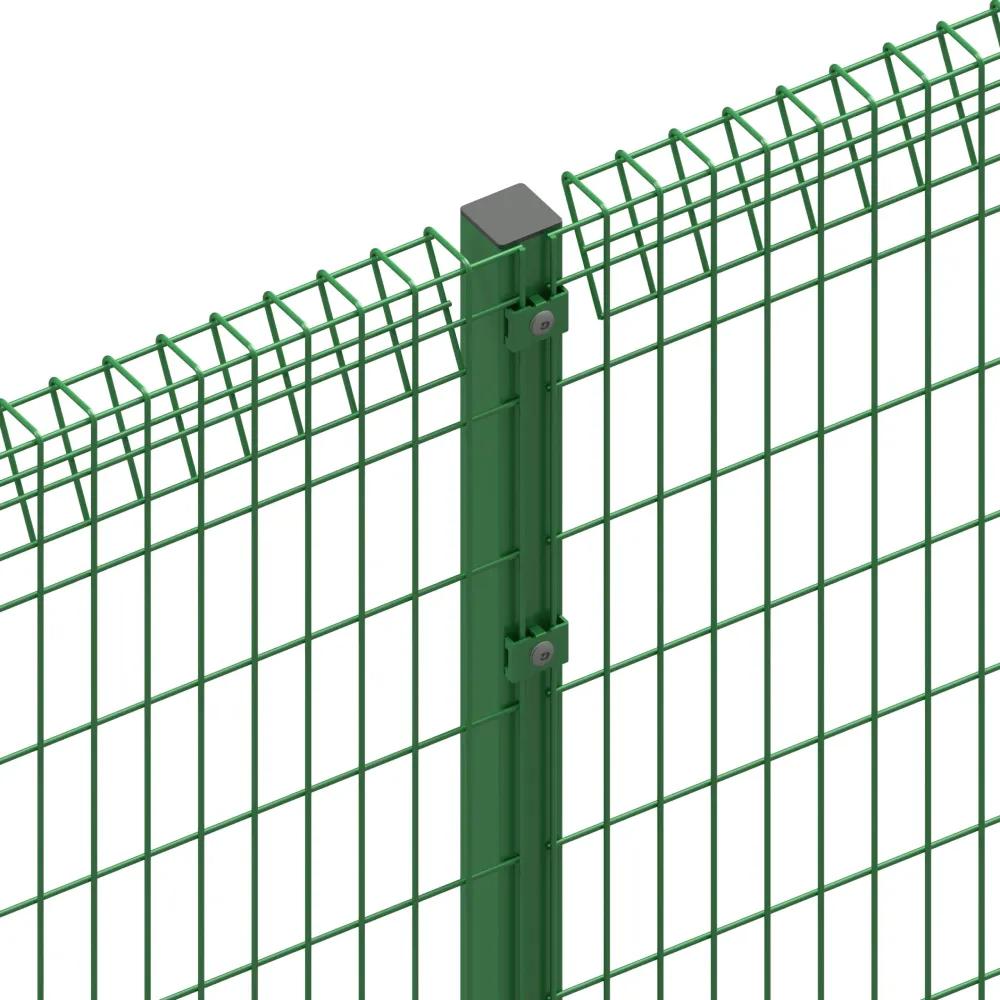

The integration of flattened mesh technology offers a myriad of benefits, granted by its ability to translate complex 3D shapes into manageable 2D representations. This method is extensively used in industries such as automotive, aerospace, and fashion, where precise material layouts are required for cutting and assembly. By using advanced algorithms, businesses can achieve highly accurate flat patterns that ensure minimal material wastage, thereby optimizing cost-efficiency and resource utilization.

Professionals experienced in computer-aided design (CAD) and computer-aided manufacturing (CAM) tools find flattened mesh models particularly advantageous. These tools provide designers with the flexibility to analyze and adjust each segment of a 3D model's surface efficiently. Expert designers and engineers rely on these models to identify potential design improvements and ensure the final product maintains structural integrity after being fabricated.

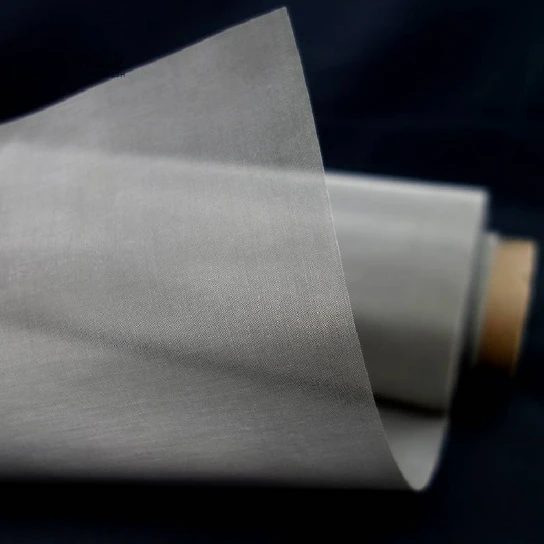

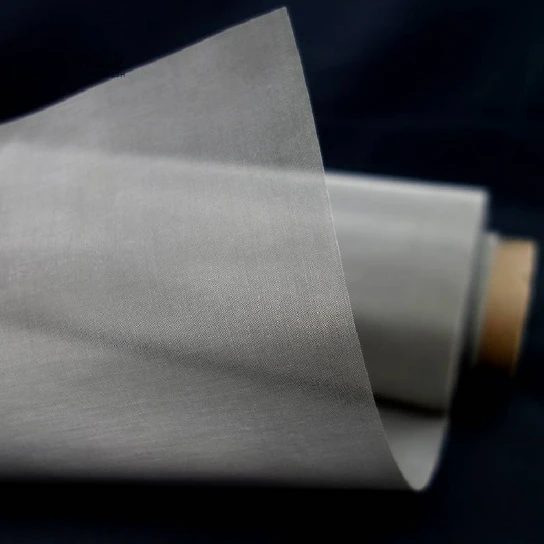

The expertise gained from adopting flattened meshes extends to optimizing structural and aesthetical components of a product. For instance, in the fashion industry, designers utilize this technique to generate patterns that fit clothing seamlessly to the human body. Furthermore, in aerospace engineering, it's employed to design structural components with precision, where even a small deviation could lead to significant functional implications.

With the authoritative input from industry leaders, the implementation of flattened mesh technology exemplifies best practices in engineering disciplines. Recognized organizations like the American Society of Mechanical Engineers (ASME) and various manufacturing consortia continuously update guidelines to incorporate advancements in flattening techniques. Consequently, these updated practices bolster the adoption of flattened meshes as a standard across sectors.

flattened mesh

Trustworthiness in the utilization of flattened mesh derives not only from its practical applications but also from the robust theoretical foundations that underpin it.

The algorithms behind mesh flattening are grounded in geometry, mathematics, and computational science. This scientific backdrop ensures that the technology remains reliable, providing consistent results across various applications, from small-scale prototyping to large-scale industrial production.

On a more experience-driven note, users who have incorporated flattened mesh into their design processes report significant enhancements in workflow efficiency. Real-world applications highlight reduced iteration times between initial concept and final production, as potential issues can be visualized and resolved in the early stages of the design process. Additionally, this technique allows for easy customization, enabling businesses to meet specific client needs more effectively.

The expertise needed to leverage flattened mesh tools effectively involves a solid understanding of computational geometry and proficiency in CAD software. Engineers and designers who master these areas can seamlessly integrate the technology into existing workflows, improving overall design accuracy and product quality. Online courses and specialized certifications can enhance the skills necessary to exploit the full potential of this technology.

An authoritative perspective on flattened mesh technologies further emphasizes its importance in staying competitive. Companies that have adopted this approach can respond more agilely to market demands while maintaining superior quality and consistency in their outputs. Trust in flattened mesh solutions is demonstrated by their widespread adoption in sectors where precision and reliability are paramount.

In conclusion, flattened mesh technology represents a fusion of advanced computational techniques and practical design applications. Its far-reaching implications across various industries underscore its necessity in modern production and design environments. As industries continue to evolve, the ability to transform complex 3D shapes into efficient, usable patterns will remain a cornerstone of innovative, cost-effective production strategies.