Wire mesh for gabion baskets serves as a cornerstone in modern landscape architecture and civil engineering projects. These versatile structures have steadily gained prominence due to their robustness, versatility, and eco-friendliness. When selecting wire mesh for gabion baskets, understanding the nuances of material quality, durability, and application-specific benefits is crucial for achieving optimal project outcomes.

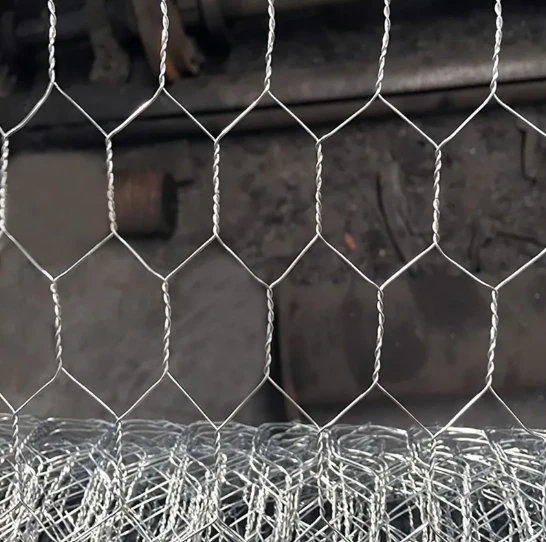

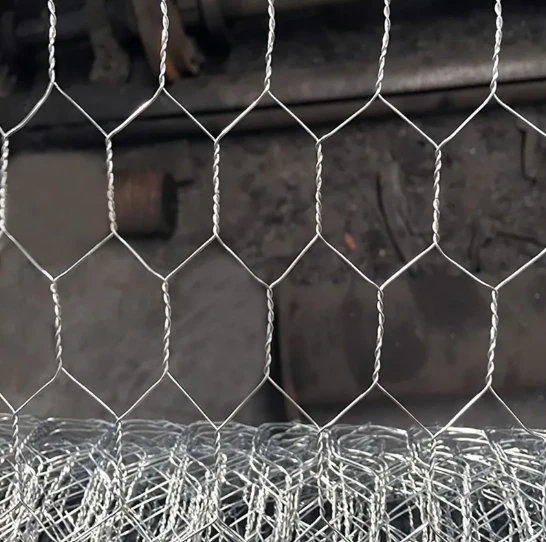

The anatomy of a gabion basket involves intertwining wire mesh filled with stones or soil. They function effectively as retaining walls, erosion control solutions, and even as decorative elements in garden design. The appeal of wire mesh gabions stems from their ability to blend seamlessly into natural landscapes while providing structural integrity.

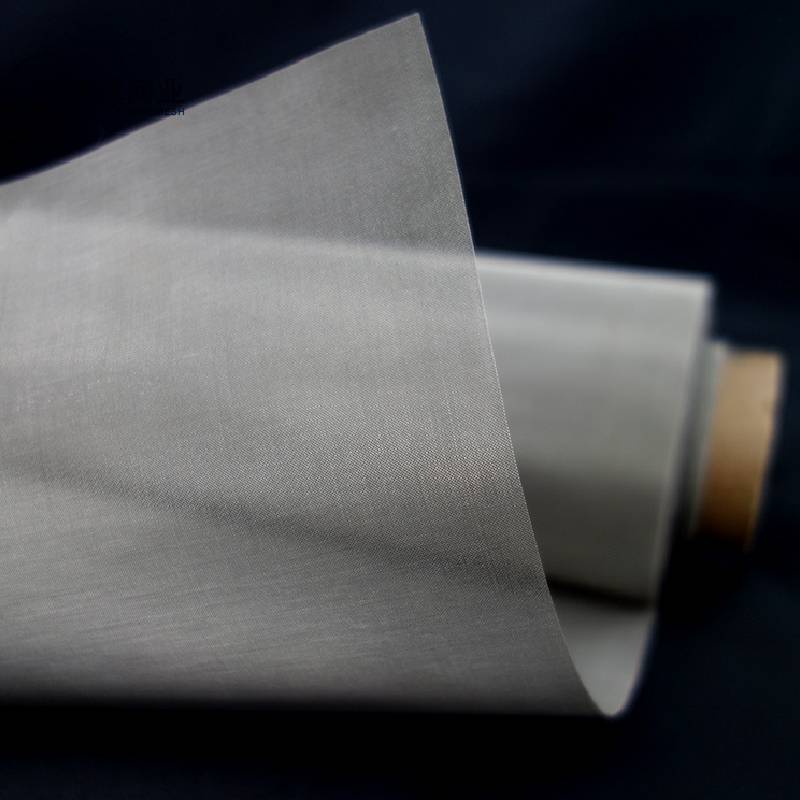

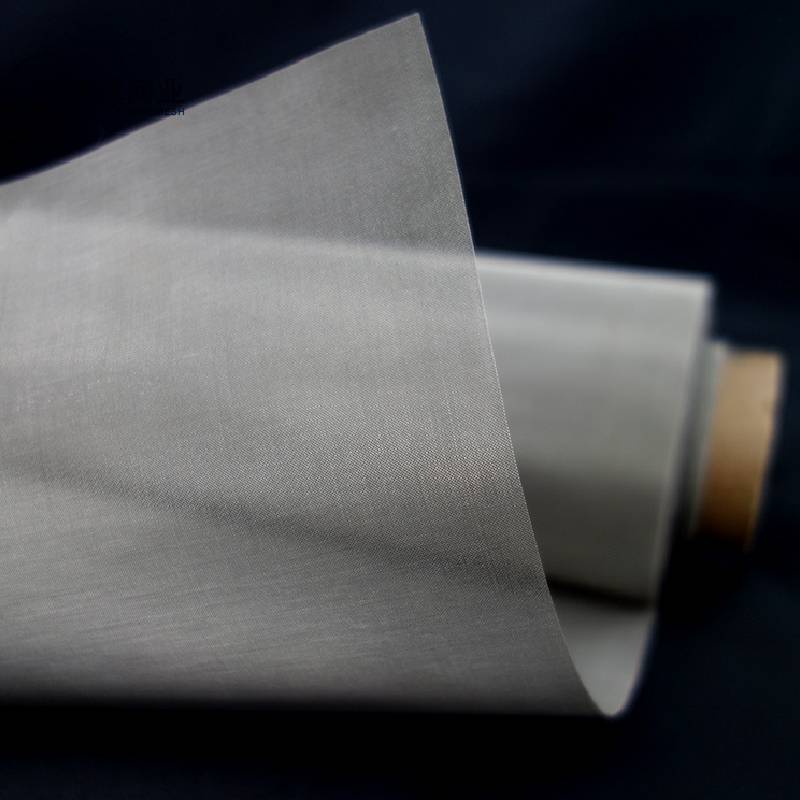

Wire mesh is typically crafted from galvanized steel, PVC-coated steel, or stainless steel. Each material comes with its own set of properties and advantages. Galvanized steel wire mesh is most cost-effective and provides substantial resistance to oxidation. However, in environments characterized by high moisture or salinity, PVC-coated or stainless-steel meshes often take precedence due to their superior resistance to rust and corrosion. The increased upfront cost of PVC-coating or stainless steel is often justified by the extended lifespan and low maintenance requirement of the gabion structure.

The wire's gauge and the mesh's aperture size significantly influence the gabion’s performance. A heavier gauge wire enhances the gabion basket’s strength, enabling it to endure greater loads and resist deformation over time. Meanwhile, appropriate aperture sizes ensure proper retention of filler material while allowing for necessary drainage that prevents water buildup and potential pressure increase behind the structure.

Application-specific selection of wire mesh incorporates factors such as load requirements, environmental conditions, and aesthetic goals. For instance, coastal projects might prioritize corrosion-resistant materials, while urban settings may emphasize aesthetic integration with existing architecture.

wire mesh for gabion baskets

From an expertise perspective, proper installation techniques ensure that the full benefits of wire mesh gabion baskets are realized. Techniques such as correct alignment, foundation preparation, and adequate anchorage are essential for stability and longevity. Experience in handling wire mesh, particularly in varying terrains and climatic conditions, distinguishes expert practitioners from novices.

Authoritative guidance often underscores the significant ecological benefits of using wire mesh gabions. Unlike traditional concrete retaining walls, gabion structures are permeable, which facilitates natural water flow and encourages vegetation growth within and around the baskets. This not only preserves the natural ecosystem but also enhances the visual appeal of the structure, allowing it to become a living part of the landscape.

The trustworthiness of wire mesh for gabion baskets as a solution is backed by decades of successful application across diverse terrains — from steep mountainous slopes to riverbanks. Case studies and long-term performance reviews affirm their efficacy in both urban and rural settings. Additionally, as regulatory bodies increasingly stress sustainable construction practices, the inherent environmental friendliness of gabion structures amplifies their acceptance and recommended use.

In conclusion, selecting the appropriate wire mesh for gabion baskets involves a balanced consideration of material selection, structural requirements, and environmental integration. By leveraging decades of industry experience, technical expertise, and a commitment to sustainability, wire mesh gabions offer a reliable, aesthetically pleasing, and eco-conscious solution to contemporary engineering challenges.