Perforated mesh panels have become a cornerstone in modern architecture and industrial applications. These versatile panels are distinguished by their lightweight properties and durability, which makes them suitable for a myriad of uses across various industries. As experts in the field, we present an in-depth exploration into the world of perforated mesh panels, detailing their applications, benefits, and the expertise required for selecting the right type.

Within architectural design, perforated mesh panels are increasingly utilized for their aesthetic appeal and functional benefits. Architects find them particularly useful for creating visually striking facades, sunshades, and interior partitions. The panels' ability to diffuse light while maintaining visibility establishes an ambiance that enhances any architectural work. More than just decorative elements, these panels contribute significantly to energy efficiency by controlling the amount of sunlight that enters a building, reducing reliance on artificial lighting and air conditioning.

The industrial sector equally benefits from the application of perforated mesh panels. Known for their high strength-to-weight ratio, these panels provide robust solutions for filtration systems, soundproofing, and safety guards in machines. They effectively separate materials in various industrial processes, ensuring operational efficiency while maintaining safety standards. The controlled permeability of the panels aids in maintaining necessary airflow, which is crucial in many manufacturing environments.

For those in the process of selecting perforated mesh panels, expertise derives from understanding the specific needs of your application. The panels come in various materials, including aluminum, stainless steel, and galvanized steel, each offering unique properties. Aluminum panels, for instance, are favored for their corrosion resistance and lightweight nature, making them ideal for coastal or humid environments. Stainless steel panels are prized for their exceptional durability and high strength, suitable for demanding industrial applications.

Precision in the perforation process ensures that the panels meet strict quality standards necessary for their reputable performance. Modern manufacturing techniques employ advanced CNC machines and laser cutting technologies to produce perforations with high accuracy, contributing to the panels' reliability and longevity.

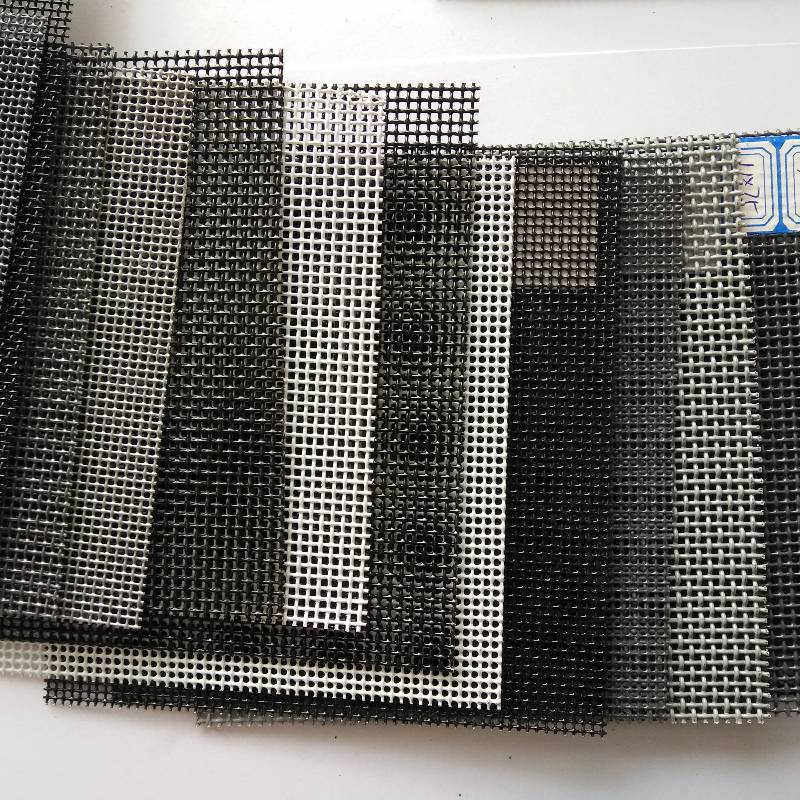

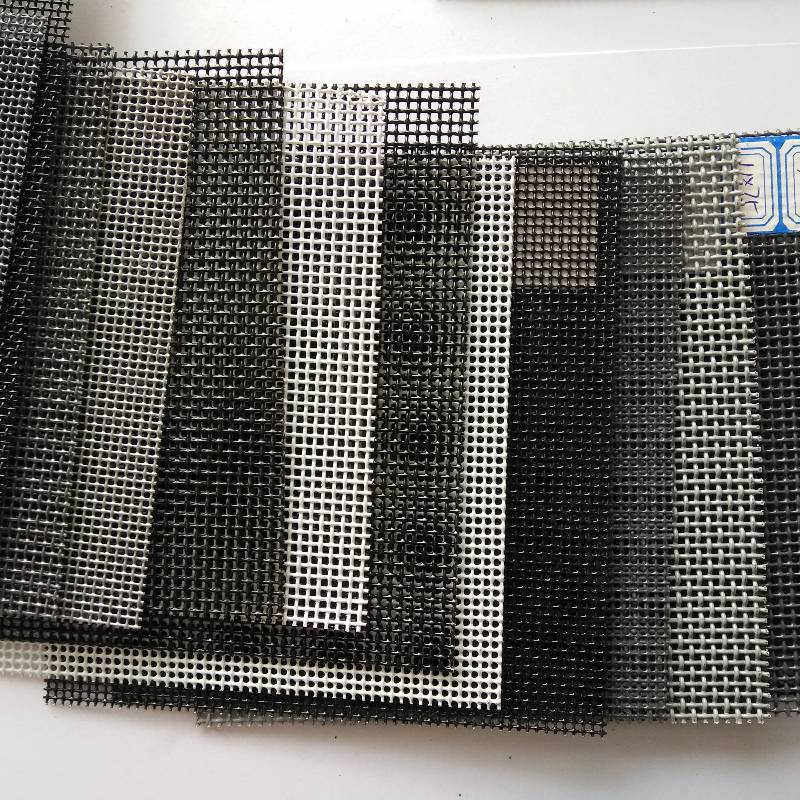

perforated mesh panels

As experts with authoritative knowledge in the field, we emphasize the importance of working with manufacturers who adhere to international quality standards. This guarantees the panels' performance and safety, providing peace of mind to architects, engineers, and industry professionals who rely on these products. Customization is another critical aspect, where bespoke designs can be engineered to meet specific aesthetic or functional requirements, an important consideration for tailored applications.

In terms of trustworthiness, selecting perforated mesh panels from reputable sources globally recognized for their commitment to quality is paramount. Many manufacturers offer certifications that attest to the panels' compliance with safety and quality regulations, underscoring their reliability in critical applications.

The global demand for perforated mesh panels continues to rise as industries and architects recognize their multifaceted benefits. Continuous innovation in materials and manufacturing processes promises to expand their applications further, paving the way for new possibilities in design and functionality. For decision-makers, entrusting suppliers with proven expertise warranties the best results, ensuring both the aesthetic value and functional integrity of their projects.

In conclusion, perforated mesh panels are more than just simple sheets of metal with holes; they are sophisticated instruments that blend form and function. By choosing the right type and working with experienced professionals, businesses and designers alike can harness the full potential of these versatile panels, securing a competitive edge in efficiency and design.