Welded wire mesh is an essential product in numerous industries, offering a blend of strength, versatility, and flexibility that makes it invaluable for many applications. When considering the selection of welded wire mesh, especially the [1 2 welded wire mesh] variant, it's crucial to understand its features, benefits, and applications to make an informed decision.

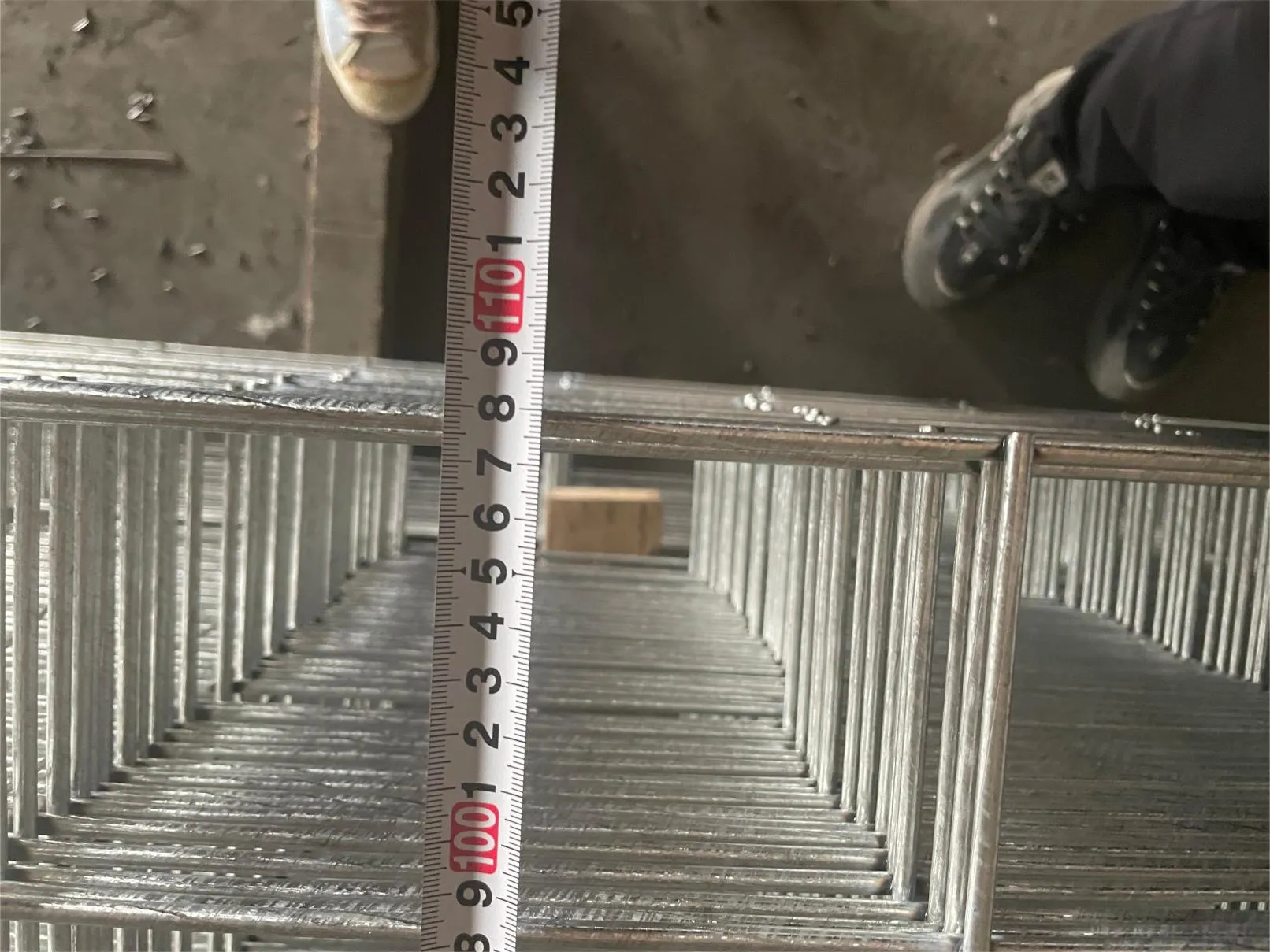

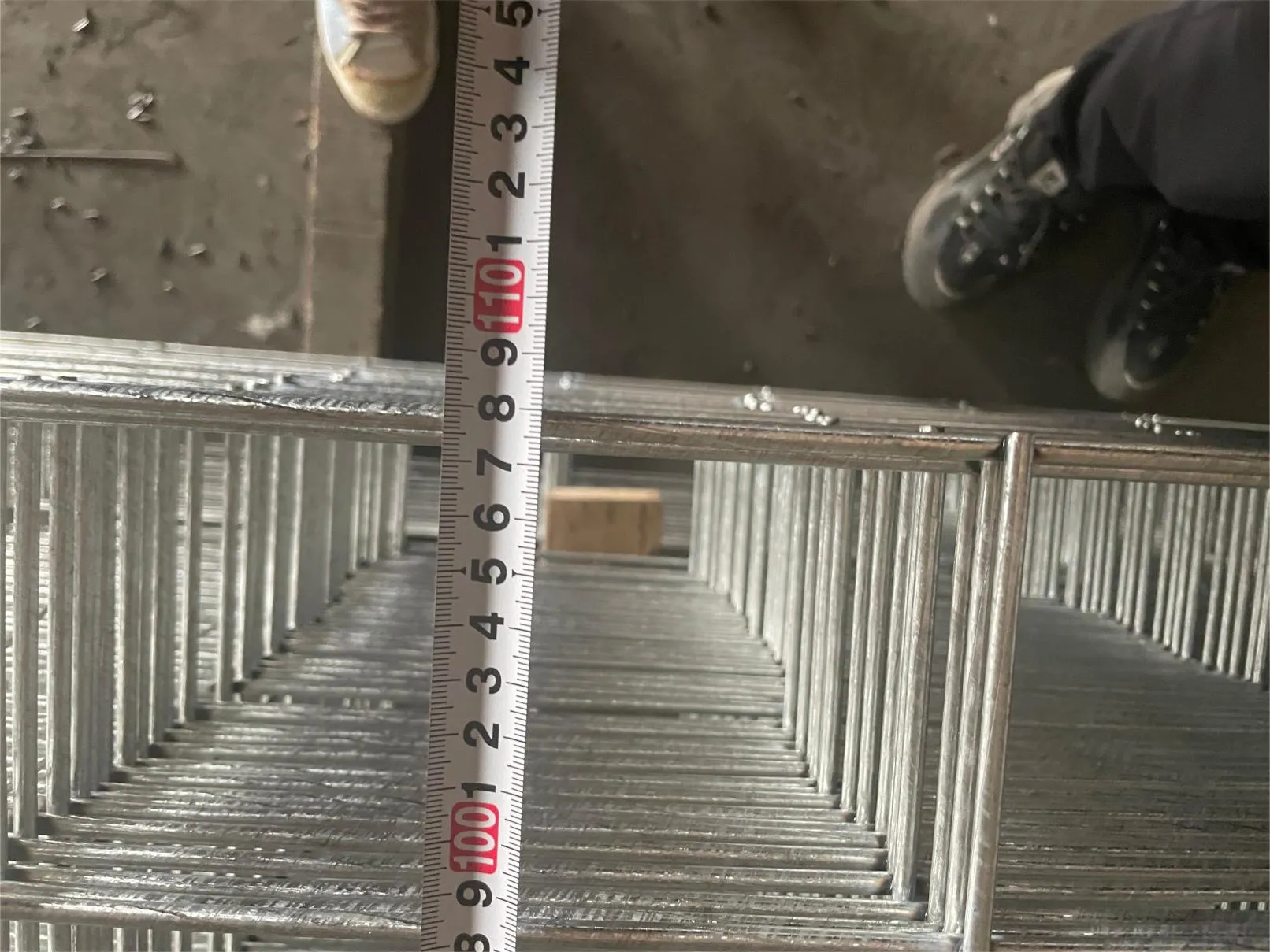

One of the primary attributes that distinguish welded wire mesh is its construction. Typically, it is made by welding wires at each intersection to form a grid. The 1 2 welded wire mesh specifically refers to a grid pattern where the apertures are of a certain size, providing a unique balance between rigidity and flexibility. This specific configuration enhances its capacity to bear loads and withstand environmental stressors, making it ideal for various demanding applications.

In the construction industry, 1 2 welded wire mesh is often utilized for reinforcing concrete. Its structure provides excellent tensile strength, which increases the durability and stability of concrete structures such as roads, walls, and slabs. The mesh effectively prevents cracking and structural failures by distributing stress along its wires, thereby extending the lifespan of concrete installations.

For agricultural purposes, this type of wired mesh serves as an excellent barrier for livestock and crops. Its robustness prevents animals from breaching enclosures while also allowing visibility and ventilation. The mesh's design offers a safe structural boundary that doesn't impede growth or access to sunlight, making it perfect for protective applications in farming environments.

In industrial settings, welded wire mesh serves multiple functions such as machine guards, safety barriers, and racks. The 1 2 variant is particularly favored for its balance of openness and strength. It offers sufficient open space for visibility and airflow, which is critical for safety and operation efficiency, while also providing the necessary strength to withstand industrial wear and tear.

A key characteristic of welded wire mesh is its corrosion resistance. Typically galvanized or coated with PVC, the mesh can resist oxidation, making it suitable for both indoor and outdoor use. This durability is essential for environments where the mesh will face exposure to moisture or chemicals, providing a reliable and long-lasting solution. When selecting a welded wire mesh, considering the coating and material is imperative to ensure longevity and performance in specific conditions.

1 2 welded wire mesh

One of the frequently overlooked advantages of welded wire mesh is its ease of installation. The 1 2 mesh panels are light enough to be handled easily, yet sturdy enough to maintain their form without requiring specialized tools for installation. This ease of use translates to reduced labor costs and time, contributing to overall project efficiency.

Many suppliers offer customization options for welded wire mesh, including material choices like stainless steel, carbon steel, or aluminum. Depending on the application, different materials can be selected to optimize the performance and cost-effectiveness of the mesh. Stainless steel, for example, provides superior corrosion resistance and aesthetic appeal, making it ideal for architectural applications.

The demand for sustainable building materials has led manufacturers to adopt eco-friendly practices in the production of welded wire mesh. Utilizing recycled materials and environmentally friendly coatings, the production process minimizes ecological impact while maintaining product integrity and strength.

Moreover, the global availability of welded wire mesh means that sourcing this material is generally convenient and cost-effective. Suppliers around the world offer competitive pricing and shipping options, allowing customers to receive the material promptly for their projects.

In conclusion, the [1 2 welded wire mesh] stands as a practical, versatile, and durable choice for a myriad of applications across different sectors. Its proven effectiveness in construction, agriculture, and industry highlights its indispensable role. Selecting the right mesh type depends on understanding the unique demands of your project and recognizing the critical attributes of this versatile material. When used correctly, welded wire mesh can significantly enhance safety, efficiency, and longevity, underscoring its position as a key component in modern infrastructure and industry.