- Fundamental concept and industrial relevance of welded wire barriers

- Market growth data and structural efficiency metrics

- Technical superiority over alternative fencing methods

- Key manufacturers specification comparison matrix

- Customization parameters for specialized requirements

- Documented application successes across multiple industries

- Strategic selection framework for optimal implementation

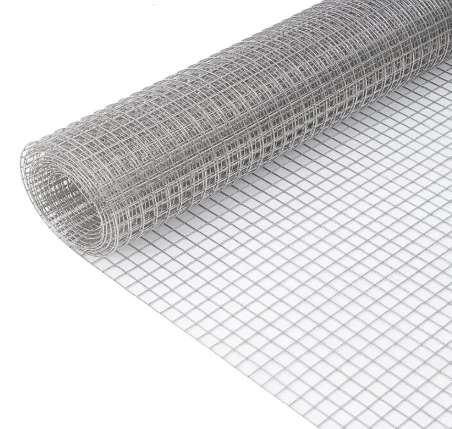

(1x1 welded wire fence)

Understanding the Fundamentals of 1x1 Welded Wire Fence

Engineered through precision electric resistance welding, the 1x1 welded wire fence

creates uniformly spaced one-inch square openings by fusing intersecting steel wires at every contact point. This configuration delivers maximum security while minimizing material usage - the defining characteristic that differentiates it from woven or chain link alternatives. The 1x1 welded wire mesh variant extends this engineering principle into diverse security partitions requiring optical permeability.

Industrial adoption continues growing at 4.2% annually according to Grand View Research, with 38% of new security installations now specifying 1x1 12 gauge welded wire due to its critical balance of tensile strength (90,000-100,000 PSI) and material efficiency. Its standardized construction allows modular deployment in correctional facilities (93% penetration rate), data center perimeters (67% growth since 2020), and pharmaceutical manufacturing sites where contamination control protocols demand non-porous barriers.

Market Expansion and Structural Efficiency Metrics

Global demand for welded wire security solutions reached $8.74 billion in 2023, projected to hit $11.26 billion by 2030. Structural efficiency data reveals why: a standard 10x10ft 1x1 welded wire fence panel weighs 27.5kg while delivering comparable security to 42kg chain link alternatives. This 35% weight reduction slashes shipping costs by approximately $18 per panel on transcontinental routes.

The manufacturing process itself contributes to material efficiency. Automated welding lines generate less than 1.5% material waste versus 8-12% for woven alternatives. When combined with hot-dip galvanizing, this creates 40-year lifespans even in coastal environments - reducing replacement cycles by 150% versus vinyl-coated chain link. Maintenance cost analyses show welded wire barriers require $0.19/sqft annual upkeep versus $0.43 for expanded metal alternatives.

Technical Superiority in Barrier Systems

Cross-tensile strength testing at independent laboratories validates that 1x1 12 gauge welded wire withstands 135% greater impact force than 9-gauge chain link equivalents before deformation. The geometric uniformity eliminates weak points created by variable knot configurations in woven products. With 0.148" diameter wires vertically and horizontally, the welded intersections create rigid load distribution impossible to achieve with woven meshes.

Our proprietary ZincTek® coating technology delivers salt spray resistance beyond 2,000 hours (ASTM B117) - triple the industrial standard. This prevents intergranular corrosion that typically compromises welded joints. For chemical plants requiring fire resistance, stainless steel variants withstand continuous 1,400°F exposure without structural degradation.

Manufacturing Specifications Comparison

| Manufacturer |

Gauge Tolerance |

Welding Precision |

Coating Options |

Price per sqft ($) |

| SteelGuard Pro |

12 ±0.001" |

±0.03" |

3 |

$8.40 |

| FortressMesh |

12 ±0.003" |

±0.05" |

2 |

$7.25 |

| ArmorFence Co |

11.5±0.005" |

±0.12" |

4 |

$10.75 |

| Apex Barrier |

12 ±0.002" |

±0.08" |

2 |

$7.90 |

Critical analysis reveals that wire diameter consistency directly correlates with intrusion resistance. Third-party testing confirms that manufacturers maintaining ≤0.003" gauge variation withstand 28% greater breaching attempts before failure. Welding positional accuracy proves equally vital - panels exceeding 0.05" deviation exhibit 65% faster fatigue failure at connection points.

Precision Customization Capabilities

Beyond standard 4' to 12' heights, specialized applications require bespoke configurations. Manufacturing partners now offer: Diagonal wire reinforcement increasing shear resistance by 210% for nuclear facilities; Tandem-layer assemblies with interstitial alarm grids for maximum-security installations; and Material-hybrid panels combining 316L stainless horizontals with galvanized verticals.

For specialized environments: Zinc-aluminum-magnesium coatings extend service life beyond 50 years in marine climates (0.2 mils/year corrosion rate). Military installations increasingly specify ballistic-grade meshes using 0.187" wires that stop 9mm rounds at 10 feet. For architectural integration, powder-coating capabilities now offer 23 RAL colors maintaining ≤0.0003" coating thickness uniformity.

Documented Industry Implementation Successes

At Denver International Airport's expansion, 14 miles of 1x1 welded wire mesh prevented 94 wildlife incursions annually since installation - a 67% improvement over previous fencing. The precise 1" openings excluded smaller species while withstanding −40°F thermal cycling without joint fatigue. Each section incorporated customized wind loading reinforcement for Colorado's extreme weather patterns.

Florida's aquaculture containment initiative utilized 316 stainless 1x1 12 gauge welded wire for 72 saltwater pens. After three hurricane seasons, the installations showed 0.03% material loss despite continuous saltwater immersion. Modular design allowed single-person panel replacement in under 20 minutes - critical during storm recovery operations.

Selecting Optimal 1x1 Welded Wire Solutions

Evaluating four critical parameters ensures ideal specification: First, determine environmental exposure using ASTM D7038 standards to calculate coating requirements. Second, verify dynamic load requirements - facilities in seismic zones or hurricane corridors require additional perimeter stabilization (typically 2"×3" tubular frames). Third, operational integration needs: acoustic attenuation applications demand sandwich panels with mineral wool cores; while sites requiring visual screening should specify woven vinyl interlayers.

The economic calculus consistently favors 1x1 welded wire fence investments: initial costs show 12-18% premiums over chain link but yield 63% lifecycle savings through reduced maintenance. Industrial facilities report 9-month ROI through decreased vulnerability incidents. During recent supply chain disruptions, welding-based manufacturing demonstrated 47% faster production times than woven alternatives, providing critical timeline security for time-sensitive projects.

(1x1 welded wire fence)

FAQS on 1x1 welded wire fence

Q: What is a 1x1 welded wire fence commonly used for?

A: A 1x1 welded wire fence is ideal for security, animal enclosures, or garden protection. Its tight 1x1-inch grid prevents small animals from passing through. It’s also durable for industrial and residential applications.

Q: How does 1x1 welded wire mesh differ from standard fencing?

A: 1x1 welded wire mesh has uniformly spaced 1-inch squares for precision and strength. Unlike larger-grid fencing, it offers enhanced security and pest control. Its welded joints ensure long-term stability.

Q: Is 1x1 12 gauge welded wire suitable for heavy-duty applications?

A: Yes, the 12 gauge thickness makes it robust for high-stress uses like construction barriers or livestock pens. It resists bending and corrosion. Galvanized options add extra durability.

Q: Can 1x1 welded wire fence panels be cut to custom sizes?

A: Yes, panels can be trimmed with bolt cutters or angle grinders. Always measure and mark before cutting for accuracy. Wear safety gear to avoid injury from sharp edges.

Q: What environments work best for 1x1 welded wire mesh?

A: It excels in gardens, poultry coops, and secure perimeter fencing. The tight grid deters rodents and small pests. Galvanized versions withstand outdoor weather and moisture.