Lightweight metal mesh is revolutionizing various industries by introducing a blend of durability, flexibility, and a reduction in the weight of products. The demand for lightweight metal meshes is driven by their multifaceted applications and the benefits they bring to the table, including enhanced energy efficiency, improved safety, and design versatility. As an authoritative voice in materials technology, it's important to delve deeper into the nuances that make lightweight metal mesh a cornerstone of innovation.

Lightweight metal mesh is employed across sectors such as aerospace, automotive, construction, and even electronics. Its widespread usage is rooted in its unique properties it is significantly lighter than traditional materials, making it indispensable for applications where weight reduction is crucial without compromising on strength. This has made it a preferred choice for components in aircraft and vehicles, offering substantial fuel savings and reducing emissions due to decreased mass while maintaining structural integrity.

In construction, lightweight metal mesh plays a critical role in modern architecture, enabling innovative design possibilities while ensuring robust performance. It is often used for facades, sunscreens, and ceilings, providing aesthetic appeal combined with practical benefits like ventilation and sound absorption. Architects and builders appreciate its adaptability and the way it complements an array of architectural styles from modern to traditional, contributing to both functional and aesthetic improvements in infrastructure.

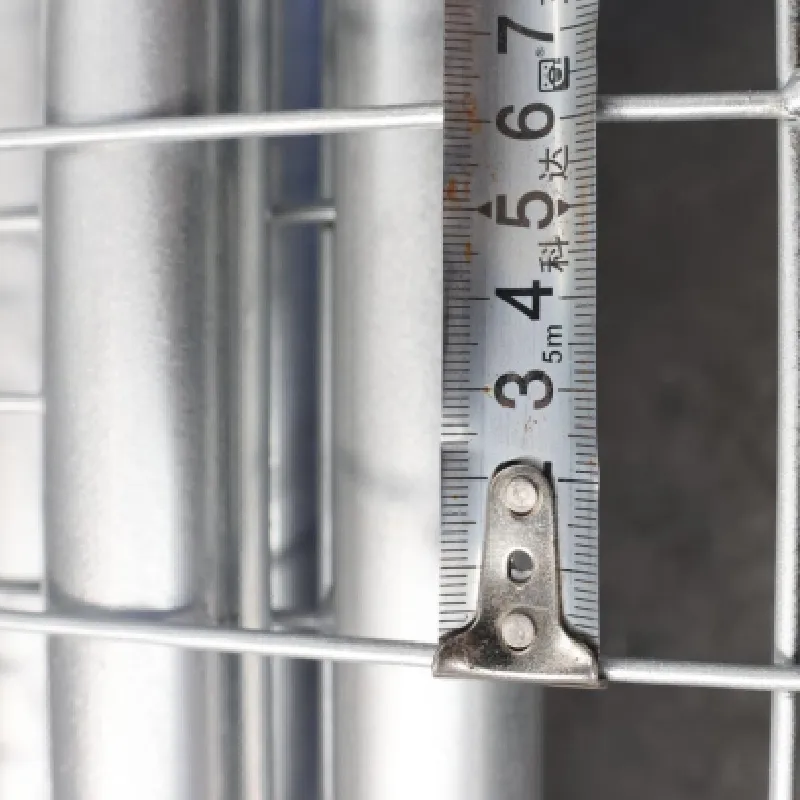

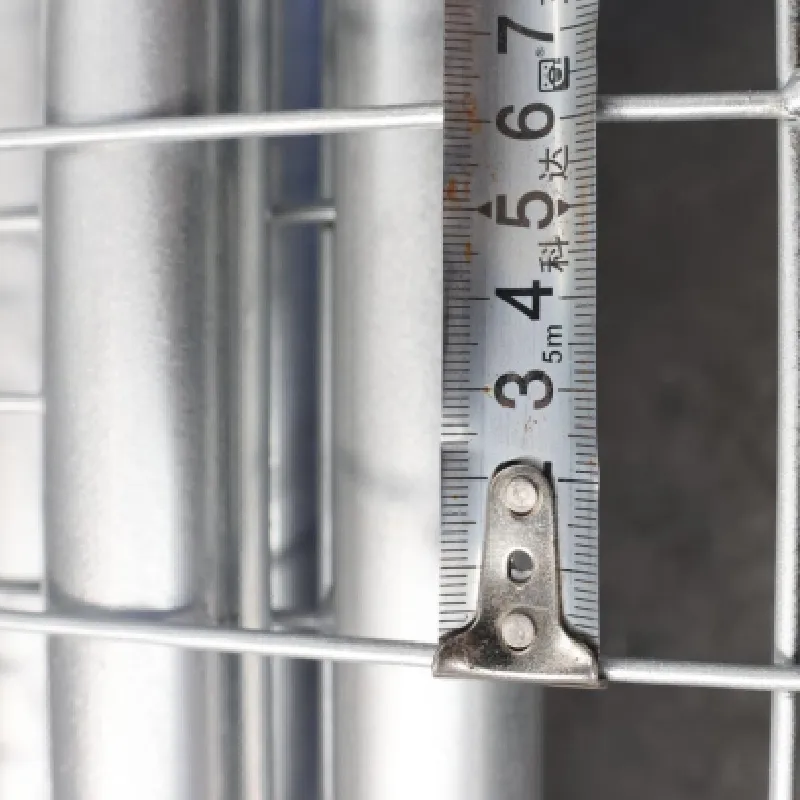

The expert consensus is that the manufacturing process of lightweight metal mesh is crucial to its qualities. Typically produced through a series of processes such as expanding, weaving, or knitting, the mesh undergoes rigorous testing to ascertain its tensile strength, flexibility, and resistance to environmental factors like corrosion. These manufacturing techniques allow for customization according to industry-specific needs, making it a versatile solution for precise application requirements. This showcases the blend of artistry and science inherent in the production of metal mesh, ensuring it meets stringent industry standards.

End-users of lightweight metal mesh can trust its reliability due to its extensive validation and certification processes that align with industry regulations. Whether it's in aerospace, automotive, construction, or electronics, users can be assured of its performance due to the rigorous quality control measures during and post-production. This trustworthiness is further solidified by the mesh's predictable performance over time, showcasing its long-term economic and operational benefits.

lightweight metal mesh

From an engineering perspective, lightweight metal mesh offers unmatched flexibility. It can be easily manipulated without losing its structural properties, making it ideal for cutting-edge engineering applications where traditional materials might falter. This flexibility ensures engineers can innovate without constraint, pushing the boundaries of what is possible across a wide array of industries.

Moreover, the sustainability factor cannot be overlooked. As industries increasingly pivot toward eco-friendly materials, lightweight metal mesh stands out as a sustainable option due to its recyclability and energy-efficient production processes. Manufacturers and users alike are recognizing the importance of reducing environmental impact, and metal mesh is at the forefront of this shift, providing a solution that aligns with sustainable practices without sacrificing performance.

One cannot talk about lightweight metal mesh without acknowledging the safety attributes it provides. For instance, in the automotive sector, it enhances safety features in vehicles through its application in crumple zones and reinforcement structures, contributing to better occupant protection. Similarly, in the field of electronics, it acts as a protective casing for sensitive electronic components, safeguarding against electromagnetic interference and physical damages.

The growing research and development in the field have unveiled new alloys and compositions that further enhance the properties of lightweight metal meshes, making them even more robust and suited to specialized applications. As industries evolve, the adaptive nature of metal mesh allows it to meet new challenges, ensuring its place as an indispensable material solution.

In essence, lightweight metal mesh represents the epitome of modern material science—a sophisticated blend of strength, flexibility, and sustainability. It not only meets but exceeds the demands of an array of industries, making it a cornerstone of innovation and efficiency for generations to come. The future of lightweight metal mesh continues to look promising as ongoing research and technological advancements pave the way for new possibilities and enhanced applications.