Metal mesh for plastering, an often overlooked yet essential part of construction and renovation projects, plays a pivotal role in ensuring structural integrity and aesthetic seamlessness. With its robust properties and versatile applications, it has become a cornerstone of modern plastering practices, fusing both conventional techniques with innovative strides in material science.

When it comes to plastering, the subconscious goal is always durability and longevity. Metal mesh serves as a foundational element to achieve these goals by providing a stable and reliable backing that prevents cracking and detachment. Whether you're dealing with interior walls or exterior facades, using a metal mesh ensures that the plaster adheres firmly to the substrate. This architectural marvel is particularly critical in areas prone to high levels of vibration or subtle ground movements, where traditional plaster could easily fail over time.

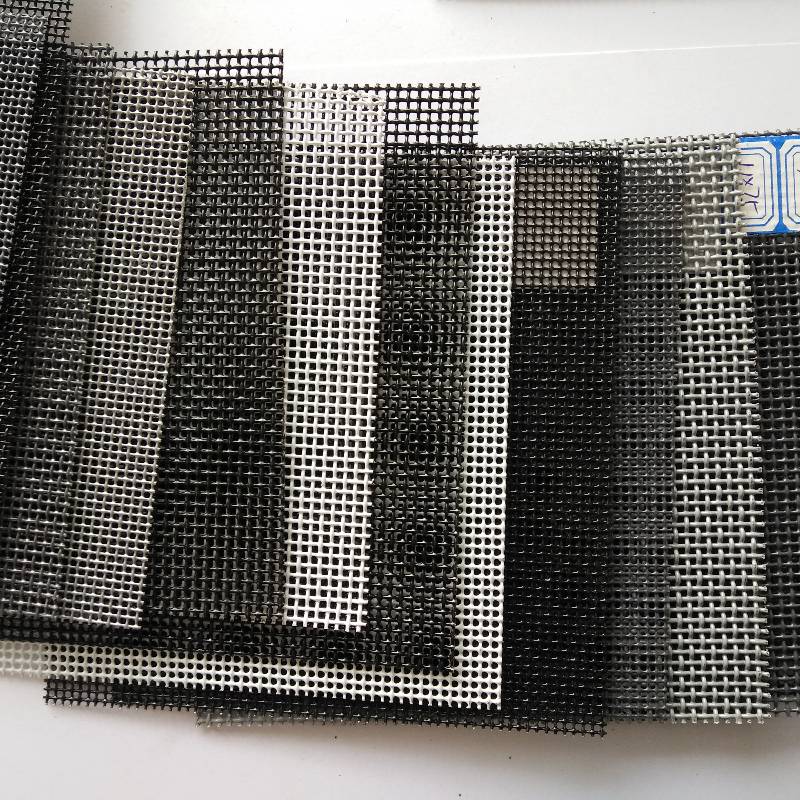

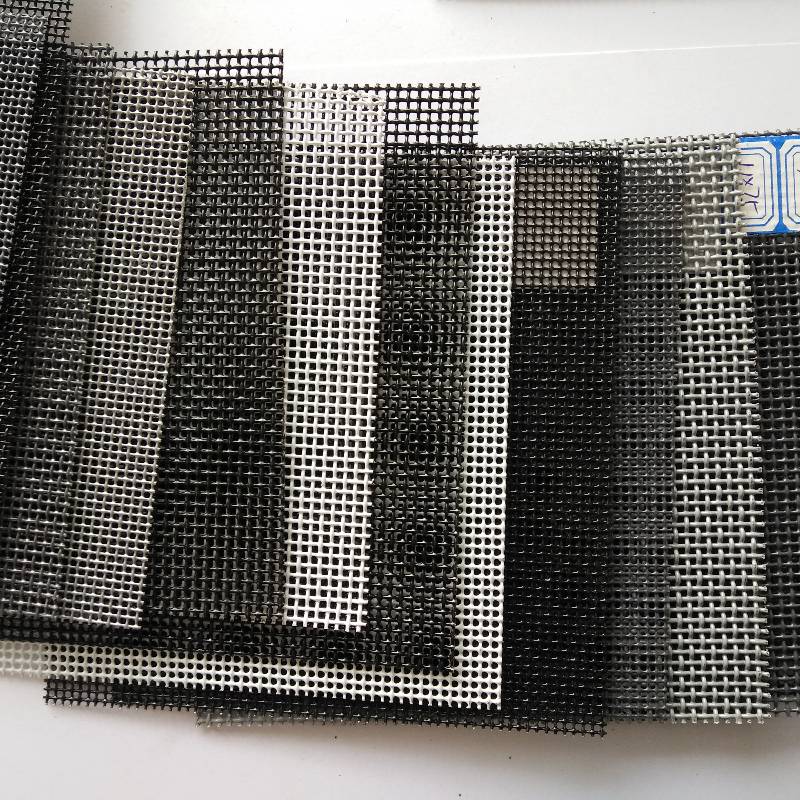

The primary allure of metal mesh lies in its composition and variety. Galvanized steel, stainless steel, and expanded metal sheets are some of the most prevalent types used in plastering. Each type has its unique properties galvanized steel offers corrosion resistance due to its zinc coating, while stainless steel promises enhanced robustness against environmental wear and tear. Expanded metal sheets provide exceptional grip for plaster, ensuring that it remains intact for decades. Selecting the right type of metal mesh depends largely on the specific requirements of a project, including environmental conditions and aesthetic desires.

What sets metal mesh apart from lesser alternatives is its unparalleled capacity to distribute stress. By dispersing applied loads evenly across its surface, it minimizes tension points that can lead to cracking. This quality not only enhances the structural soundness of the plastered wall but also extends its lifespan significantly. In commercial and residential buildings alike, this translates to lower maintenance costs and higher long-term value — a win-win for property owners and investors.

Professionals lauding the benefits of metal mesh often emphasize its flexibility during installation. Unlike rigid chiari or other underlayments, metal mesh can conform to uneven surfaces, offering a bespoke fit without compromising on strength. This flexibility is vital when dealing with unconventional designs or when renovating older buildings where walls often present unforeseen challenges. The mesh can be easily cut and molded into the necessary shape, ensuring an optimal fit in every application.

metal mesh for plastering

The efficiency of installation is another compelling reason to choose metal mesh in plastering. Its lightweight nature reduces the labor intensity typically associated with pre-plaster preparations, accelerating project timelines and cutting down labor costs. Furthermore, its grid-like pattern provides an effortless guide for precision work, ensuring consistent thickness and uniformity in plaster applications. This translates into smoother finishes, a critical factor for achieving high-quality visual results in decorative and functional plastering alike.

Beyond its structural and economic advantages, the metal mesh offers environmental benefits that resonate with sustainability-focused projects. Many of these meshes are crafted from recycled materials, and their durability further contributes to reducing environmental waste by minimizing the need for frequent repairs or replacement. As the construction industry moves towards sustainable practices, incorporating metal mesh for plastering aligns with green building strategies and enhances a project's eco-friendly profile.

To harness the full array of benefits provided by metal mesh, expertise in handling and installation is paramount. A seasoned professional understands the subtleties of mesh selection and application techniques, guaranteeing optimal results that stand the test of time. Thus, investing in skilled labor and thorough training is just as crucial as choosing the right materials.

In conclusion, metal mesh is more than a simple accessory in the plastering domain; it is a catalyst for quality, durability, and sustainability. By choosing this material, builders and homeowners invest in the future of their structures, ensuring that their design aspirations are met with enduring success and reliability. By understanding its importance and application nuances, one can transform ordinary plastering projects into extraordinary feats of architectural resilience.