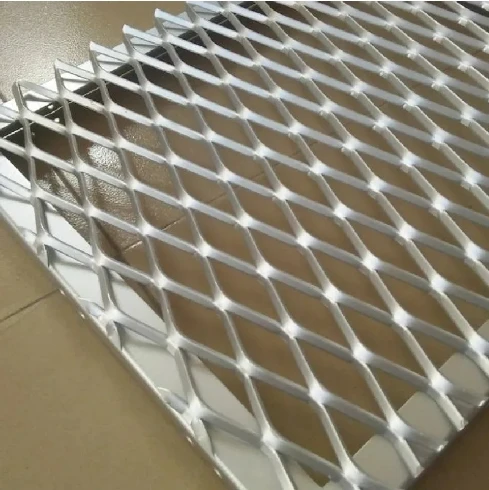

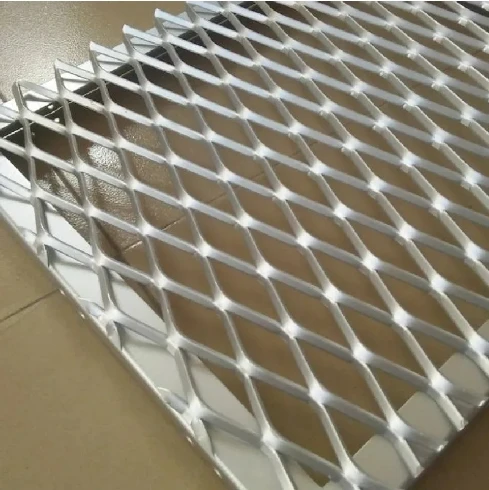

Expanded steel mesh sheets are transforming industries with their versatility and durability. These sheets, crafted through an intricate process of slitting and stretching, form a pattern of metal mesh that combines strength with flexibility. Professionals across fields recognize their value, drawing upon experiences that highlight their practical applications and inherent benefits.

Within the construction industry, expanded steel mesh sheets are lauded for their resilience. Contractors often find these sheets indispensable for reinforcement tasks in concrete structures. The open pattern of the mesh allows concrete to grip better, enhancing the tensile strength of the composite material. This method of reinforcement boasts decades of use and widespread trust due to its proven effectiveness in enhancing buildings’ structural integrity against seismic activities and heavy loads.

Moreover, architects often appreciate the aesthetic flexibility these mesh sheets offer. With designs focusing on blending utility with modern aesthetics, expanded steel mesh provides a unique textural element that complements contemporary architectural styles. Used in façades, ceilings, and even as partitions, these mesh sheets lend a modern industrial look that marries form with functionality. Architects with experience in sustainable design also commend it for allowing natural light diffusion while maintaining privacy – a quality increasingly sought after in sustainable building practices.

Beyond construction, the automotive industry has integrated expanded steel mesh sheets into its processes, contributing notably to vehicular design and manufacturing. The lightweight yet robust nature of the material allows designers to push boundaries in aerodynamics, enhancing fuel efficiency without sacrificing safety or performance. Engineers highlight the material’s ability to reinforce without weighing down, citing applications from structural support in vehicle chassis to intricate detailing in car interiors.

Professionals in the field of filtration and separation have long venerated expanded steel mesh sheets for their role in creating superior filters and sieves. The customizable size of the mesh openings makes them ideal for various filtration levels, which is essential in industries ranging from pharmaceuticals to oil and gas. Technological advancements have further refined the production of these sheets, leading to even more precise and efficient filtration solutions. Experts in chemical processing point to the mesh’s resistance to corrosion as a significant advantage, maximizing durability and operational lifespan.

expanded steel mesh sheet

Manufacturers also recognize the sheets’ contribution to enhancing safety and security. They are extensively used in fabricating guards and grilles that protect machinery and equipment, ensuring safe operation standards across many industries. The expanded mesh design effectively disperses impact force, offering protective solutions without sacrificing visibility or airflow, which is crucial in maintaining equipment performance.

The expertise behind expanded steel mesh sheet production is not to be understated; it is a testament to technological advancements in metallurgy and manufacturing processes. Professionals involved in its production underscore the meticulous quality control measures that ensure every sheet meets precise specifications for holes, thickness, and strength, fostering trust among clients who rely on these products for critical applications.

While the advantages are manifold, experts in material sciences and industrial applications continuously research ways to enhance and innovate uses for expanded steel mesh sheets. Laboratories worldwide are delving into alloy variations, refining production techniques, and exploring post-production treatments like galvanization, to improve corrosion resistance or add aesthetic finishes. This ongoing research and development solidify the authoritative standpoint that expanded steel mesh sheets remain at the forefront of multifunctional material solutions.

In conclusion, the multifaceted utility of expanded steel mesh sheets is evident across numerous industry sectors. Their reliability, coupled with aesthetic and practical adaptability, has cemented their status as a staple material choice. The profound trust placed in these sheets is a reflection of the collective expertise and experience of countless professionals who validate their efficacy daily. As industries evolve, the innovative potential of expanded steel mesh sheets continues to grow, underscoring their remarkable role in modern industrial applications.