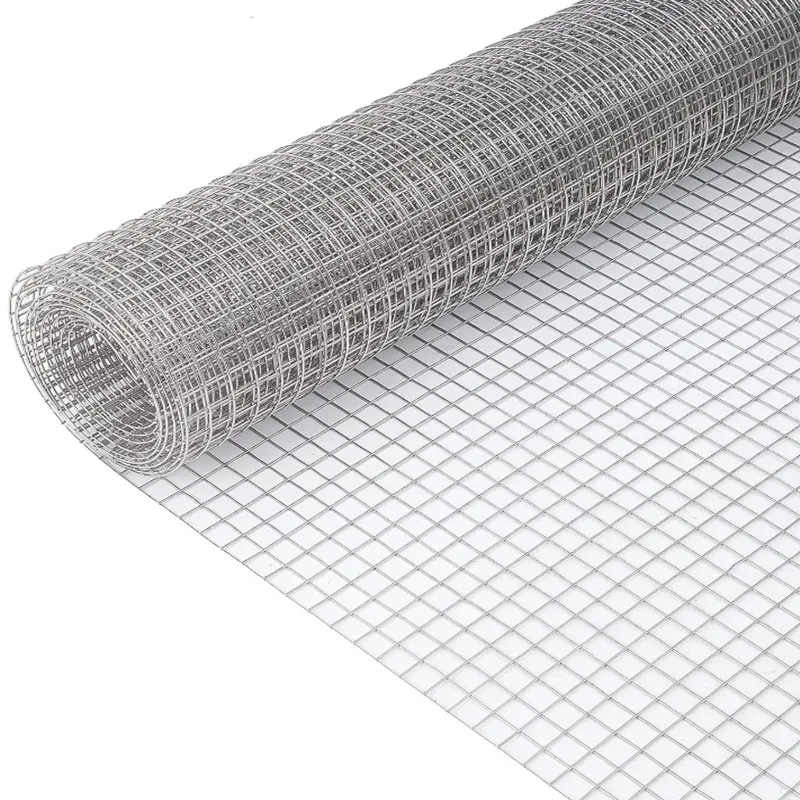

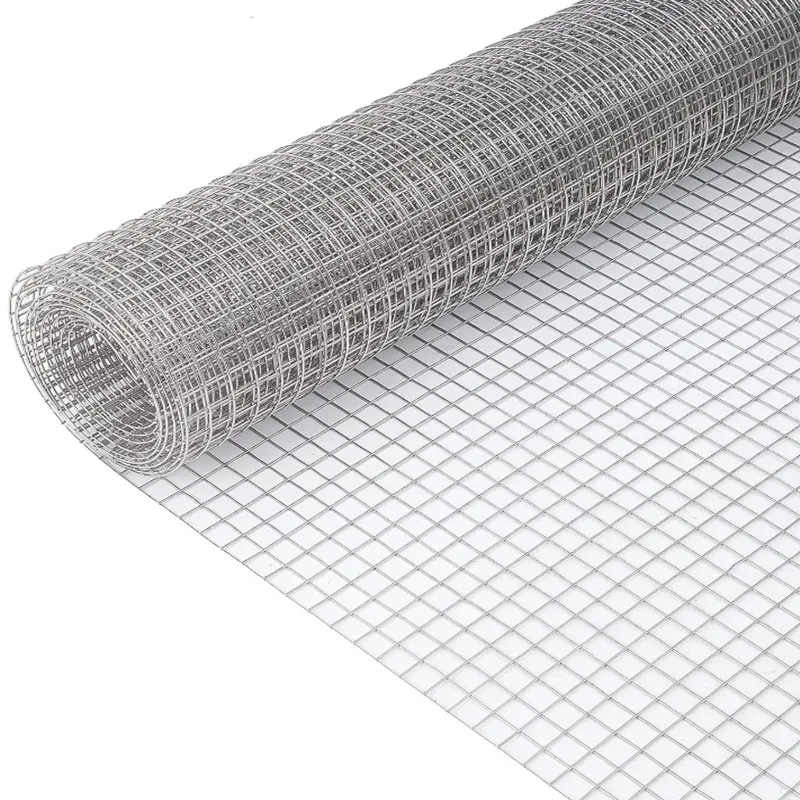

Expanded metal mesh is a versatile and innovative material that has carved its niche in various industries due to its functionality, aesthetic appeal, and economic efficiency. Imagine a single sheet of metal that you can transform into a myriad of applications, each more exotic and practical than the next. That's the magic of expanded metal mesh—a powerhouse product that combines strength, flexibility, and breathability in ways few other materials can match.

What sets expanded metal mesh apart is the unique process by which it’s created. From a foundational perspective, it involves the simultaneous slitting and stretching of a metal sheet, typically steel, aluminum, or stainless steel. This process not only retains the material’s original integrity—allowing it to maintain a singular structure without welds—but also results in a product that is considerably stronger and lighter than traditional metal meshes. You can imagine the tensile strength of a structured metal sheet combined with the malleability of a fabric-like material.

From an engineering standpoint,

this distinct manufacturing process yields several advantages. First, the mesh design disperses load across a larger area, enhancing its structural capabilities and resilience to wear and tear. Secondly, the open sections allow for air and light to penetrate, which can be critical in settings ranging from architectural facades to industrial filtration. Additionally, the expanded character of the mesh increases the surface area, which is highly beneficial for applications such as cathodic protection in corrosion-prone environments.

Exploring its uses further, one cannot overlook its role in architecture and construction. The aesthetic potential of expanded metal mesh is immense—a modern architect's dream. Its ability to add texture and depth while also playing with light and shadow dynamics makes it extraordinarily valuable in projects aiming for sustainability and visual appeal. Architects rely on its lightweight nature that significantly cuts down on support structure needs, subsequently reducing project costs and resource allocation. Moreover, its ability to provide ventilation while acting as a protective barrier is ideal for environmentally conscious designs.

In industrial contexts, expanded metal mesh serves as a critical component in machinery and equipment. Its robust nature provides reliable safety guards and barriers, ensuring machinery operates safely without compromise. The mesh also finds its place in flooring and grating, offering impressive anti-slip properties and allowing substances like oil and water to pass through, maintaining safe walking surfaces and efficient drainage systems.

expanded metal mesh

What amplifies the credibility of expanded metal mesh within various industries is its unparalleled compliance with durability standards. Tested and approved to withstand harsh environmental conditions, this material refuses to falter under exposure to extreme temperatures, corrosive chemicals, or physical impacts. This reliability forms the bedrock for its adoption in critical infrastructure applications, including platforms, bridges, and high-rise buildings.

Consider the feedback from industrial veterans like John Taylor, a structural engineer with over 20 years of experience. He emphasizes, “The adoption of expanded metal mesh across construction sectors has revolutionized how we think about building durability and design. Its adaptive nature allows for unprecedented customization while ensuring safety and efficiency.”

Further cementing its authority, numerous governmental and environmental agencies endorse its use for infrastructure development, thanks to its recyclability and minimal environmental footprint. Its ability to be repurposed easily without degradation aligns with current global sustainability trends and regulations.

In summary, expanded metal mesh is not just a product; it’s a comprehensive solution that meets the dynamic challenges of modern engineering and design. By integrating expanded metal mesh into a project, stakeholders benefit from its durability, cost-effectiveness, and remarkable adaptability. Its standing in the market is not just backed by its physical attributes but also its proven track record in delivering beyond expectations, making it an essential asset in any project aiming for excellence in functionality and aesthetics.