Aluminum tread plate, often recognized for its distinctive raised diamond or linear patterns, is an essential component within various industrial and architectural applications. Its unique properties render it indispensable, especially in scenarios demanding structural integrity coupled with aesthetic appeal. Unraveling the versatility, durability, and technical attributes of aluminum tread plate offers invaluable insights for professionals seeking optimized metal solutions.

Aluminum tread plate’s preeminence stems from its resilience and adaptability in challenging environments. The material is renowned for its non-slip surface, courtesy of its textured patterns, which enhances safety in industries such as transportation, where slip resistance is crucial. For instance, in the manufacturing of vehicle flooring, the implementation of tread plate minimizes the risk of accidents related to slipping, thereby bolstering workplace safety.

Its lightweight nature confers an additional advantage. Comparatively lighter than steel, aluminum tread plates do not compromise on strength, making them ideal for applications demanding a high strength-to-weight ratio. This trait particularly benefits the construction and aerospace industries where reducing weight without sacrificing strength can result in significant cost savings and efficiency enhancements.

A further exploration into its material properties reveals aluminum’s inherent corrosion resistance. Unlike iron and steel, aluminum forms a protective layer of oxide, which shields it from rusting and extends its lifespan in harsh environments. This makes it a superior choice for applications exposed to moisture or saltwater, common in marine settings. Engineers and architects often prefer aluminum tread plate for dock surfaces and ship interiors, attributing to its longevity and minimal maintenance requirements.

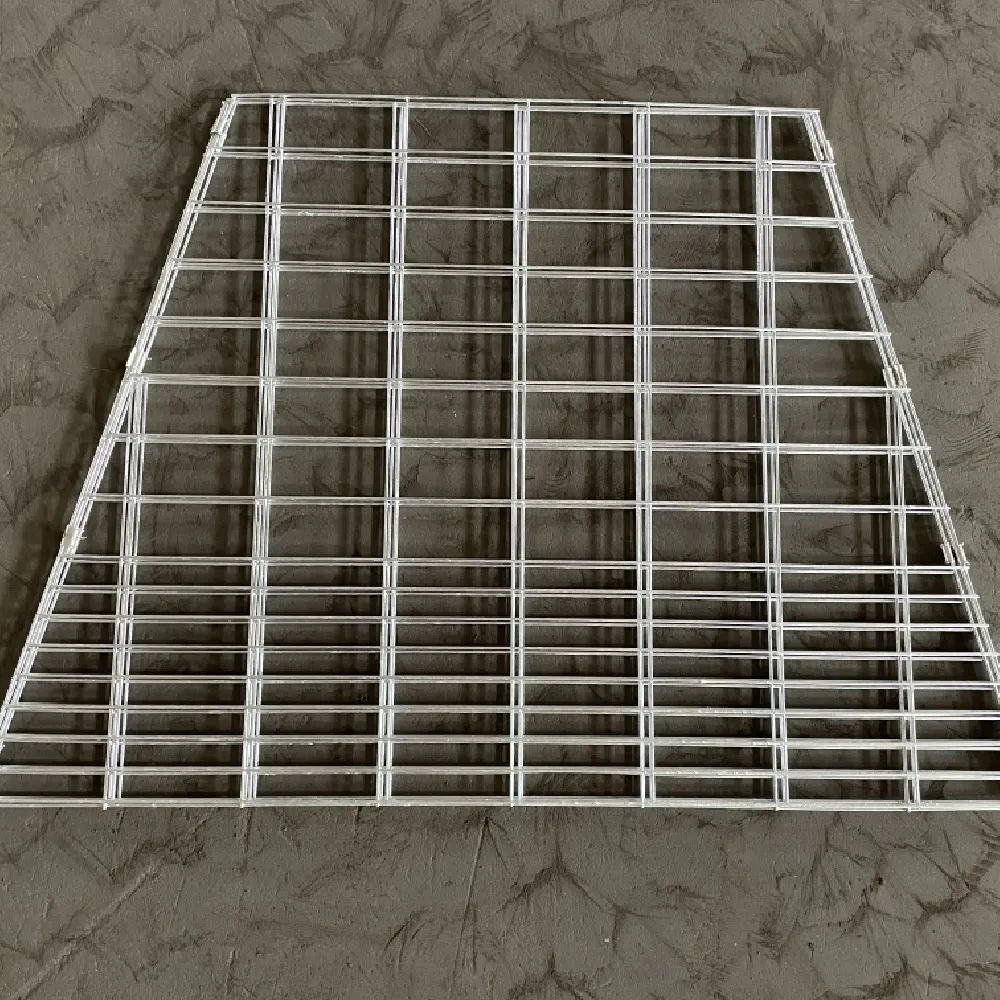

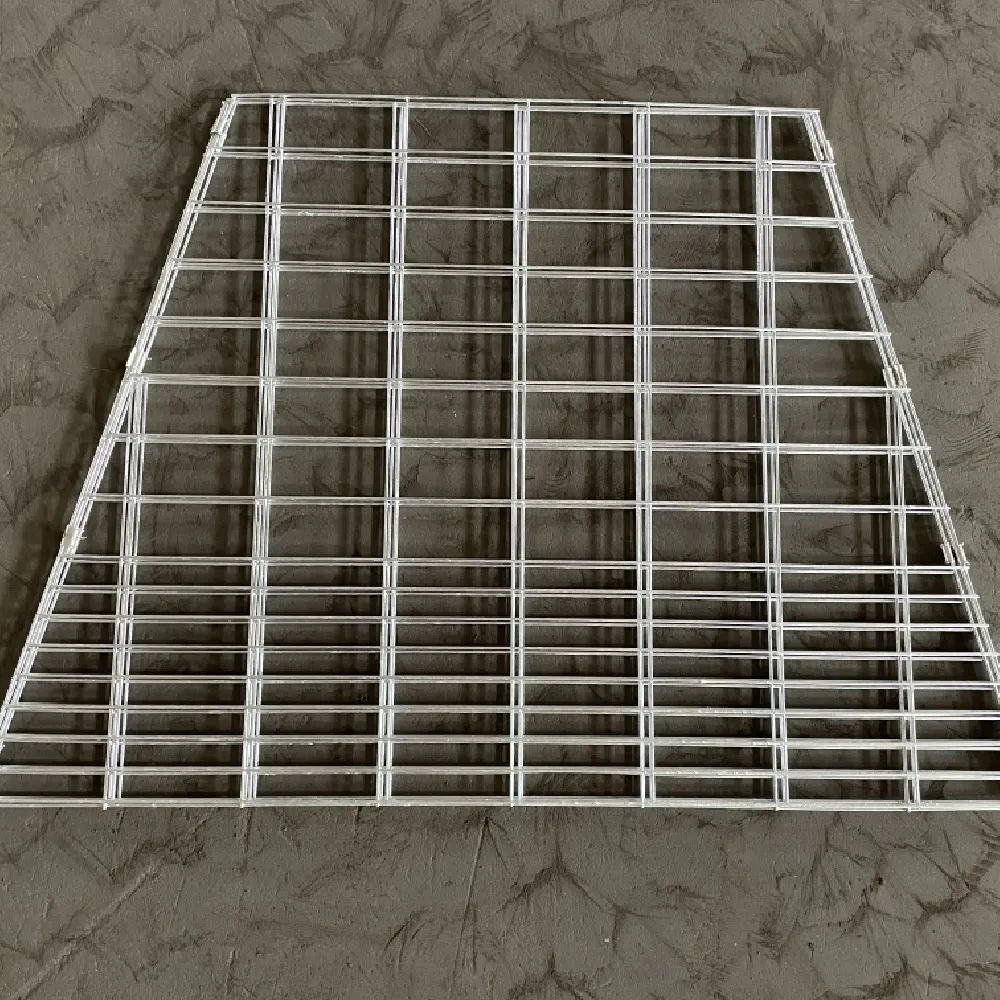

aluminum tread plate

The adaptability of aluminum tread plate extends beyond its mechanical properties. With advancements in anodizing and painting techniques, aluminum plates are available in a plethora of finishes and colors. This allows designers the creative freedom to use the material in decorative applications while maintaining its functional benefits. Consequently, interior designers and architects utilize it in contemporary settings to add a modern, industrial aesthetic to spaces such as staircases, storefronts, and interior wall cladding.

Equally noteworthy is the material’s sustainability. Aluminum is 100% recyclable; it can be melted down and reused without degradation of its properties. This aligns with the growing demand for environmentally sustainable solutions across industries. Companies committed to sustainability are increasingly choosing aluminum tread plates as they endeavor to reduce their ecological footprint. This sustainable lifecycle approach not only caters to environmental responsibilities but also positions businesses favorably in markets where eco-consciousness is rewarded.

Moreover, the simplicity of installation enhances its appeal across numerous sectors. Its ease of fabricability, combined with welding and fastening technologies, simplifies the installation process and reduces labor costs. This practicality facilitates large-scale projects where budget and timelines are critical, confirming aluminum tread plates as a cost-effective choice.

Ultimately, the enduring utility of aluminum tread plate lies in its multifaceted applications, robust durability, and the ability to seamlessly blend functionality with aesthetics. As industries continue evolving towards more sustainable, efficient, and innovative solutions, aluminum tread plate remains at the forefront, offering an unmatched combination of performance and adaptability. It stands as a testament to optimized material engineering, underpinned by its contributions to safety, efficiency, and sustainable practices worldwide.