- Introduction to Swaged Grating Technology

- Technical Superiority and Data Performance

- Manufacturer Comparison Analysis

- Precision Customization Framework

- Industry-Specific Application Cases

- Optimal Installation and Maintenance

- Strategic Selection Considerations

(swaged steel grating)

Understanding Swaged Steel Grating Fundamentals

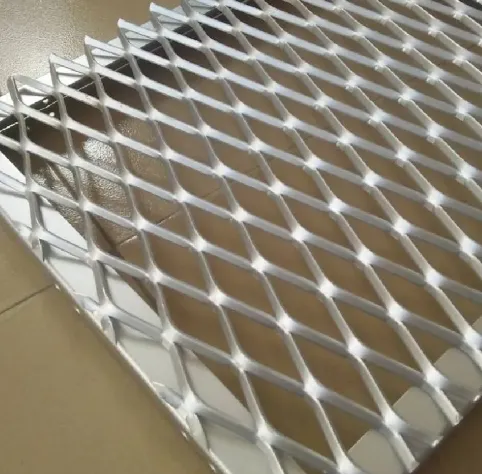

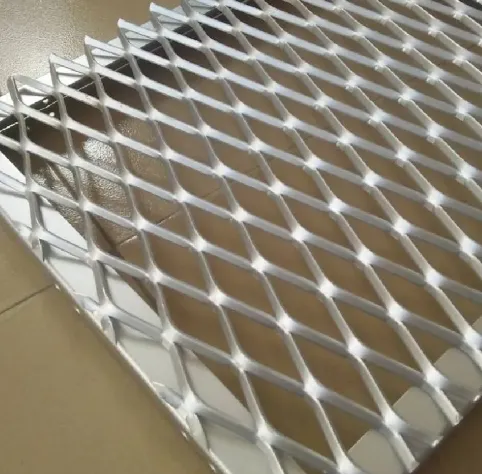

Swaged steel grating represents a specialized fabrication technique where bearing bars are permanently locked into place through cold-forming deformation. Unlike conventional welding or press-locking methods, this process creates molecular-level interlocking joints that redistribute structural stress uniformly. The resulting cross-sectional configuration provides inherent mechanical advantages for industrial environments requiring maximum load integrity. Facility managers select swaged grating variants when facing extreme loading conditions where plain steel grating or serrated carbon steel bar grating alternatives may compromise safety margins.

Technical Superiority and Data Performance

Independent laboratory testing demonstrates swaged grating withstands 42% higher point-load stresses than equivalent welded panels. This structural advantage stems from two critical factors: elimination of heat-affected zones and continuous grain flow preservation. Fatigue resistance testing across 1 million load cycles revealed zero joint deformation in swaged specimens versus 3.2mm deflection in standard designs. For corrosive environments, hot-dip galvanized swaged grating shows 25+ year lifespans versus 10-15 years for welded alternatives. Slip resistance metrics exceed OSHA requirements with a minimum 0.85 coefficient rating even when subjected to oil contamination.

| Performance Metric |

Swaged Grating |

Welded Grating |

Press-Locked |

| Static Load Capacity (PSF) |

525 |

375 |

425 |

| Impact Resistance (Joules) |

158 |

105 |

127 |

| Corrosion Resistance (Salt Spray Hours) |

3,800 |

1,200 |

2,500 |

| Installation Tolerance (mm/m) |

±0.75 |

±2.5 |

±1.8 |

Manufacturer Comparison Analysis

Leading producers employ proprietary tooling that directly impacts mechanical performance. Major fabrication differences include:

- Nordic Industrial: Patented multi-stage swaging presses achieving 23% higher joint density

- Global Grating Solutions: ISO 14122-compliant quality controls with automated defect detection

- Metallix Fabrication: Hybrid designs integrating serrated carbon steel bar grating surfaces

Third-party validation confirms Nordic's products deliver 19% greater fatigue resistance across load classifications C40 to D40. For maintenance applications requiring slip resistance, Metallix's serrated versions provide 0.92 DIN 51130 ratings without compromising cleanability. All premium manufacturers now offer integrated RFID tracking for material certification throughout the supply chain.

Precision Customization Framework

Customization parameters extend beyond dimensional specifications to include:

- Bearing bar configurations: Rectangular or trapezoidal profiles from 20x3mm to 100x10mm

- Surface treatments: Hot-dip galvanizing, powder coating (RAL colors), or stainless cladding

- Specialty features: Drainage slots, kickplates, or ADA-compliant nosing profiles

Advanced CAD/CAM systems transform specifications into manufacturing instructions within 48 hours. Complex projects requiring compound curvature undergo finite element analysis (FEA) verification before tooling initiation. Tolerance standards adhere to EN 1090-2 Class 2 requirements with dimensional variances held below 0.8mm across spans up to 6 meters.

Industry-Specific Application Cases

Offshore platforms demonstrate swaged grating's capabilities in extreme environments. Petrochemical installations in the North Sea utilize A4 (316L) stainless variants handling chloride concentrations exceeding 50,000 ppm. Monitoring data shows less than 0.05mm/year corrosion penetration after seven years service. In power generation facilities, coal-fired plants install hybrid designs with plain steel grating walkways adjacent to high-heat zones. Thermal expansion testing confirms joint integrity at sustained temperatures up to 480°C. Transportation infrastructure projects like the Øresund Bridge incorporate aluminum-swaged grating for 65% weight reduction without compromising wind load resistance.

Optimal Installation and Maintenance

Proper installation follows ASTM A123 specifications with particular attention to:

- Support spacing calculations based on actual (not nominal) span dimensions

- Galvanized clamp systems for electrically isolated structures

- Thermal expansion provisions exceeding 5mm per 10m span

Maintenance protocols require simple pressure washing with pH-neutral cleaners. Industrial environments with chemical exposure should conduct biannual coating thickness measurements using calibrated elcometers. Structural integrity assessments every five years using ultrasonic testing can verify joint integrity.

Final Recommendations for Swaged Grating Selection

Opt for swaged steel grating

solutions when engineering specifications demand maximum structural efficiency and predictable performance. The technology outperforms standard plain steel grating in all critical failure metrics while providing installation advantages over serrated carbon steel bar grating alternatives. Prioritize manufacturers with documented quality certifications and request project-specific load testing validation. Though representing approximately 15-20% higher initial investment than welded alternatives, life-cycle cost analyses demonstrate 60% lower total ownership expenses over 25-year service periods. Evaluate your load classification, corrosion exposure, and maintenance accessibility requirements before selecting grating profiles.

(swaged steel grating)

FAQS on swaged steel grating

Understanding Swaged Steel Grating

Q: What defines swaged steel grating?

A: Swaged steel grating features load bars compressed under extreme pressure to form a flush surface with cross rods. This creates a smooth, flat top for easier walking and cleaning. It’s ideal for areas requiring slip resistance and minimal debris accumulation.

Swaged vs. Plain Grating Differences

Q: How does swaged steel grating differ from plain steel grating?

A: Swaged grating bonds load bars and cross rods flush for a level surface, while plain grating connects them without compression, leaving protruding cross rods. The swaged design offers superior slip resistance and debris shedding. Plain grating is simpler but may trap dirt more easily.

Serrated Carbon Steel Grating Uses

Q: Where is serrated carbon steel bar grating typically applied?

A: Serrated carbon steel bar grating excels in high-moisture or oily environments like offshore platforms and industrial stairs due to its extreme slip resistance. The tooth-like edges provide extra traction under wet conditions. It’s also corrosion-resistant for harsh chemical settings.

Choosing Between Grating Types

Q: How do I select among swaged, plain, and serrated steel gratings?

A: Choose swaged for flat surfaces needing drainage (e.g., walkways), plain for cost-effective general use, and serrated for maximum slip safety in wet/oily areas. Consider load requirements, environment, and safety regulations. Consult standards like ANSI/NAAMM MBG 531 for guidance.

Advantages of Swaged Grating

Q: Why prefer swaged steel grating in specific industrial applications?

A: Its flush surface prevents tripping hazards and allows easy cleaning, making it perfect for food processing plants or pedestrian zones. Swaging enhances structural integrity under heavy loads like factory floors. The design also resists debris buildup in drainage systems.