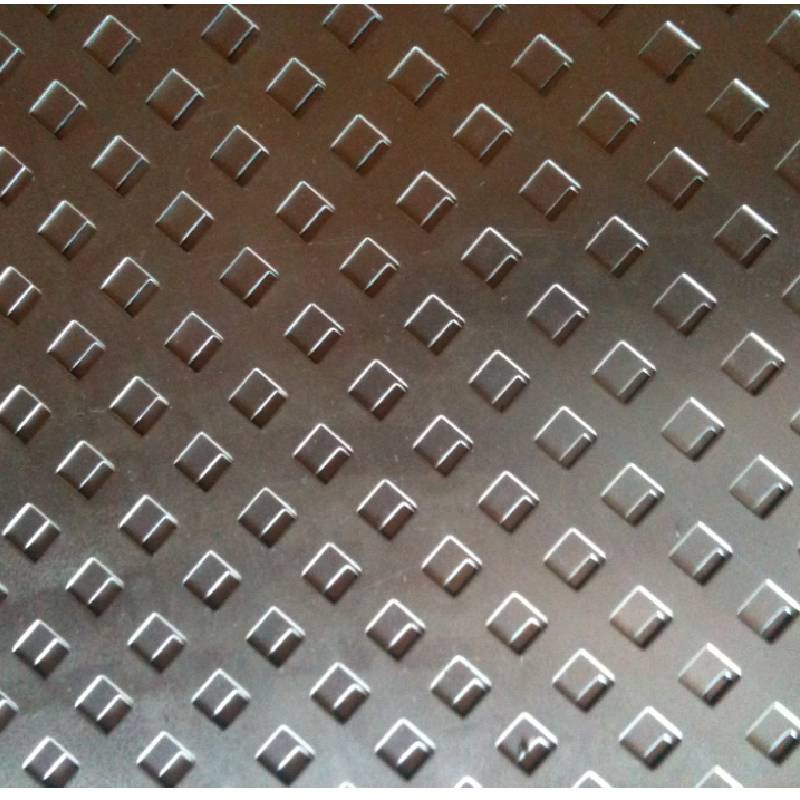

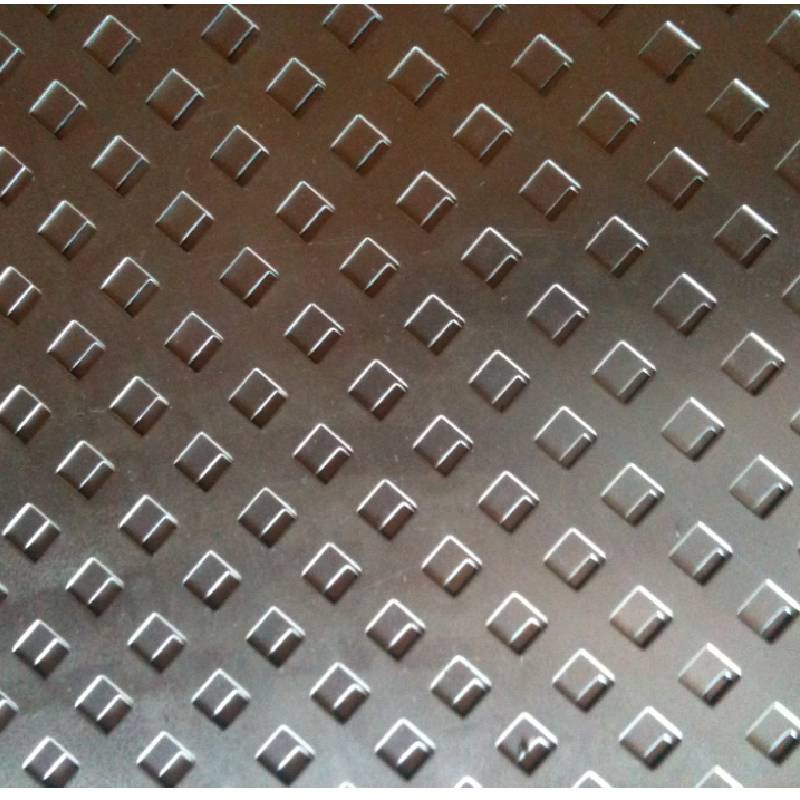

Weld mesh, a versatile material often referenced in the construction and manufacturing industries, has revolutionized how various sectors approach building and design. Understanding the nuances of weld mesh can elevate the decision-making process for architects, builders, and DIY enthusiasts alike. Here are some insights into the features, applications, and benefits of weld mesh, drawing from deep-seated expertise and real-world applications.

Weld mesh is typically constructed from low-carbon steel, galvanized steel, or stainless steel, which contributes to its strength and durability.

These materials are welded at intersections to form a sturdy and reliable mesh grid. The precise welding employed ensures that the structural integrity of the mesh is maintained even under high pressure or challenging environmental conditions. This manufacturing process underscores the authority of weld mesh in demanding applications where robustness is non-negotiable.

From an application standpoint, weld mesh serves as a backbone in several industries. In construction, it is frequently employed as a reinforcement for concrete, providing additional tension resistance to stave off cracking. This has been pivotal in building safe and long-lasting infrastructures such as bridges, highways, and residential projects. The ease of installation and the reduced weight compared to solid steel bars make weld mesh an attractive option for cost-conscious projects without compromising on strength or stability.

In agriculture, weld mesh finds utility in creating secure enclosures and fencing for animals. The resilience of the mesh ensures that animals remain contained and protected from predators. Moreover, the open grid design allows for maximum visibility and ventilation, crucial for the health of livestock. The adaptability of weld mesh to various farm configurations is a testament to its effectiveness and reliability in outdoor and rural environments.

Manufacturers of furniture and designers of urban elements have also turned their attention to weld mesh due to its aesthetic and functional appeal. The grid's rhythmic pattern has inspired modern designs that emphasize simplicity and geometric beauty. Weld mesh chairs, tables, and art installations are now common, blending industrial robustness with contemporary style to create pieces that are both visually striking and highly durable.

weld mesh

The expertise required in selecting the appropriate type of weld mesh involves understanding the specific needs of each project, particularly concerning gauge thickness and aperture size. For areas prone to environmental degradation, such as coastal regions, opting for stainless steel weld mesh is a wise choice due to its superior resistance to corrosion. Conversely, for projects where cost is a primary concern, galvanized weld mesh offers a balance between performance and affordability.

Purchasing weld mesh from reputable suppliers assures adherence to industry standards and quality. Before making a purchase, verifying the weld mesh's certifications and track record can instill confidence in its performance and longevity. Collaborating with suppliers who offer technical support and installation guidance can mitigate risks and streamline project execution, ensuring that every application derives maximum utility from the chosen mesh type.

Trustworthiness in this domain extends beyond the product itself to encompass after-sale support and customer service. Suppliers who stand by their products typically offer comprehensive warranties and responsive assistance to address any discrepancies or issues that may arise during or after installation. This commitment to quality reinforces the trust clients place in weld mesh as a foundational element in both temporary and permanent structures.

Real-world experience consistently validates the decision to employ weld mesh across diverse scenarios. Whether used in safety applications such as security fencing and cages or as a cost-effective alternative in project-specific installations, weld mesh delivers reliability and efficiency. Testimonials from seasoned contractors and project managers highlight the mesh's contribution to reduced labor time and enhanced safety standards, solidifying its role as a staple in material planning and execution.

In conclusion, weld mesh embodies a blend of strength, versatility, and simplicity, supported by a wealth of expertise and practical applications. Its widespread use across industries is not merely a testament to its inherent properties but also a reflection of the trust and authority it commands among professionals. As industrial demands evolve, weld mesh continues to prove its worth as a material that balances innovation with tradition, offering solutions that withstand the test of time.