Steel grating prices can be a key factor affecting project budgets and decision-making for industries across the board. Understanding the dynamic nature of these prices requires a grasp of market trends, manufacturing costs, and the specific requirements involved in each unique project, all while leveraging industry expertise to make informed purchasing decisions.

Steel grating is an essential component used extensively in construction, industrial platforms, and other applications requiring robust and durable surface solutions. The price of this product can fluctuate by region, largely influenced by raw material costs, market demand, and global steel production levels. Apprehending these factors is vital for businesses that frequently incorporate steel grating into their projects.

Materials, Processing, and Design

The cost of steel grating is chiefly determined by the materials used and the complexity of the design. Stainless steel, carbon steel, and aluminum are the most common materials, each with distinctive properties that affect price. For instance, stainless steel offers corrosion resistance and higher durability, often resulting in a premium price compared to carbon steel. On the other hand, aluminum might be chosen for its lightweight properties, which can influence overall project costs positively due to easier handling despite higher initial material costs.

Furthermore,

the manufacturing process also contributes significantly to the price. Bar grating, for instance, is crafted through a series of forging processes that guarantee strength and stability, but these added steps contribute to higher manufacturing costs. The complexity of the grating design, whether it's welded or press locked, can affect the price too. Customized designs matching specific load-bearing requirements or compliance standards may drive costs higher, considering the specialized production processes involved.

Market Demand and Production Capacity

The principle of supply and demand plays a pivotal role in influencing steel grating prices. Over the past decade, fluctuations in global steel production, geopolitical tensions, and transportation costs have all impacted market prices. When production is high and demand steady, prices may stabilize or even lower. However, unexpected events, such as trade tariffs or natural disasters affecting raw material supply, can result in sudden price hikes.

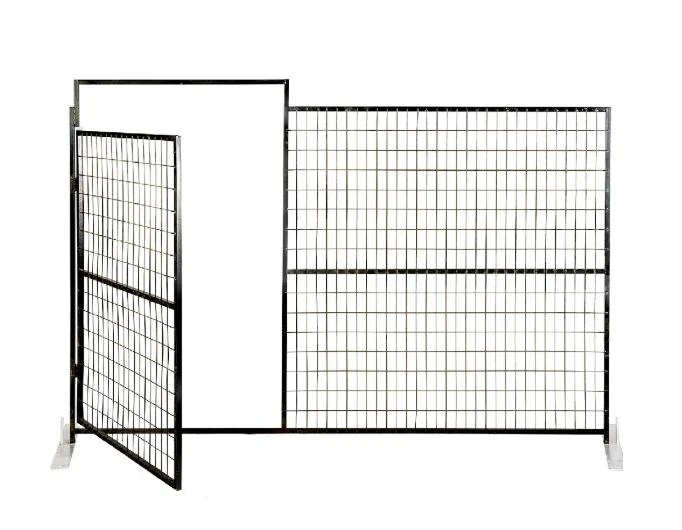

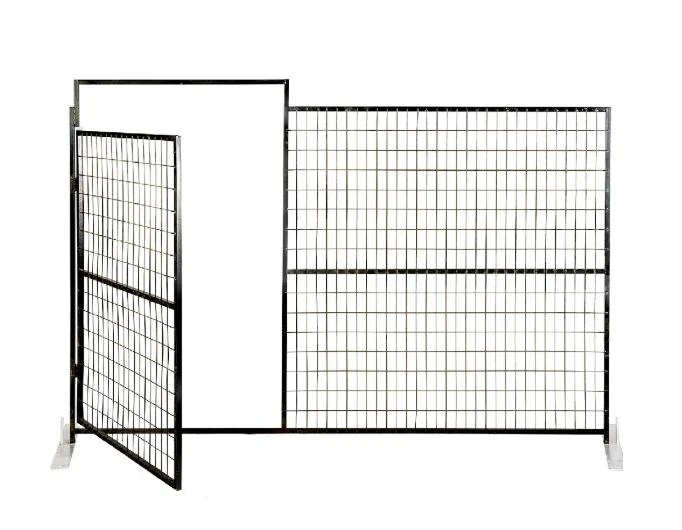

steel grating price

Manufacturers' production capacities also influence pricing strategies. In regions where production capacity is limited, prices tend to be higher due to the scarcity of the product. Conversely, larger manufacturers with greater production capabilities may offer more competitive pricing, often due to economies of scale.

Trustworthiness and Vendor Expertise

In navigating these complexities, selecting a reliable vendor with deep market expertise is critical. Partnering with an authoritative supplier who can provide transparent pricing and tailored advice based on industry trends ensures more accurate budgeting and project planning. These vendors often share insights into future price changes, allowing businesses to make preemptive purchasing decisions.

Real-World Experiences

Industry veterans often share that the most successful projects are those that account for flexible budget margins to accommodate potential material price increases. For example, a construction company working on a large-scale infrastructure project might allocate a contingency budget specifically for material costs, particularly when working with essential components like steel grating susceptible to price volatility.

Moreover, technical advances, such as new coating technologies for steel grating, can offset expenses related to maintenance and longevity, providing a cost-effective option in the long term. Establishing relationships with suppliers who remain at the forefront of these innovations ensures access to the latest, efficient products.

In conclusion, while the price of steel grating is influenced by several determining factors, awareness and strategic planning, guided by experienced vendors, can lead to more reliable and cost-efficient project executions. Understanding these nuances helps industry players make decisions grounded in knowledge, ultimately securing better returns and success in their respective endeavors.