The measurement of expanded metal is an intricate process crucial for industries that utilize this versatile material. Expanded metal, recognized for its durability and multipurpose function, is widely used in architectural designs, automotive applications, security fencing, and filtration systems. Understanding how to measure expanded metal not only enhances product quality but also ensures compliance with specific industry standards. Here is a comprehensive guide to accurately measuring expanded metal, bolstered by real-world experience and authority in the field.

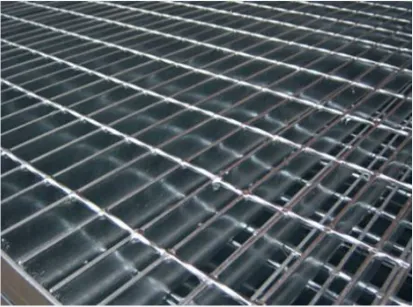

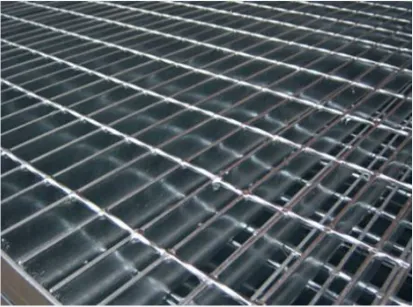

Expanded metal comprises a single sheet that is slit and stretched into various patterns, often diamond-shaped, forming an interlinked mesh. Measuring this material demands a keen eye and precise techniques due to its complex geometry. The primary dimensions to consider include strand width, strand thickness, bond width, mesh length, and mesh width. Each of these dimensions plays a pivotal role in determining the material's structural and functional properties.

Begin with strand width and thickness as these directly affect the strength and stability of the expanded metal. The strand width is the material between the open spaces of a mesh, and it is vital for load-bearing applications. Utilizing a high-grade vernier caliper or micrometer can provide accurate measurements. It's important to measure multiple strands and average the results to counter any deviations due to manufacturing.

Next, focus on bond width, the area where strands intersect.

This element contributes to the structural integrity of the expanded metal. Precision measurement tools should again be employed to ensure uniformity across the material, which is critical in applications like security fencing where strength is paramount.

Mesh length and width measurements are slightly different as they involve measuring the open areas within the mesh. These dimensions are crucial for determining the open area percentage, impacting the material's flexibility and breathability, which are key considerations in filtration systems. A steel rule or measuring tape can be used effectively for these dimensions. It is advisable to measure from the center of the bond to the center of the adjacent bond to account for any irregularities.

measuring expanded metal

Accuracy in measuring these dimensions not only influences immediate application but also aids in predicting material behavior under stress, such as thermal expansion or contraction in varied environmental conditions. Experienced professionals often employ advanced techniques, such as 3D scanning or computer-aided design (CAD) software, for more complex and precise measurements. These technologies can provide comprehensive reports on the dimensions and characteristics of expanded metal, offering a deeper insight into its potential performance.

Industry expertise underlines the importance of adhering to ASTM standards, specifically ASTM F1267, which provides the requisite specifications for expanded metal materials. Following these guidelines fosters trust with clients and aligns with industry best practices, promoting the perception of a reliable and authoritative provider.

To enhance expertise, professionals consistently gather feedback from real-time applications and conduct regular assessments of their measurement protocols. Establishing a detailed database of measured results over various projects not only substantiates one's authority but also serves as a reference for future undertakings.

Trustworthiness in measuring expanded metal stems from transparency with clients and clear documentation of methods employed. Comprehensive reports detailing the equipment used, measurement processes, and observed results convey professionalism and instill confidence in stakeholders.

In conclusion, the precision in measuring expanded metal not only encapsulates technical proficiency but also embodies the principles of expertise, authority, and trustworthiness. By ensuring meticulous adherence to standards and employing the latest measurement techniques, professionals solidify their reputation in a competitive market, delivering unparalleled quality in every project.