Galvanized metal mesh has long been a cornerstone in industries ranging from construction to agriculture, epitomizing strength and versatility. Renowned for its durability and resilience, this metal mesh serves as a reliable material in various applications, offering unparalleled protection and longevity.

The manufacturing process of galvanized metal mesh involves coating steel or iron with a layer of zinc, which is achieved through a method called galvanization. This zinc coating is crucial, as it fortifies the metal mesh against rust and corrosion, especially in outdoor environments where weather conditions can be unpredictable and harsh. Not only does this coating enhance the lifespan of the mesh, but it also ensures minimal maintenance, making it a cost-effective solution over time.

Industries deeply reliant on galvanized metal mesh appreciate the robustness it provides. In construction, it's common to find the mesh utilized in reinforcing concrete, fencing properties, or as a component in false ceilings. Its role here is fundamental, providing stability and resilience, which are essential for safety and structural integrity. Agricultural sectors leverage this adaptability to secure perimeters against intruders and animals and create pen enclosures due to its ability to withstand environmental stress while still providing a clear view of enclosed areas.

The versatility of galvanized metal mesh is further exemplified in its use within the filtration industry. The fine, interwoven metal creates a screening resource that can capture even the smallest particles, making it invaluable in both industrial filtration systems and air ventilation systems, where it aids in maintaining clean and efficient operations.

From a sustainability perspective, galvanized metal mesh stands out. The longevity provided by the zinc coating means replacements are infrequent, reducing material wastage. Furthermore, galvanized metal is recyclable, aligning it well with environmental standards and practices, thus making it a smart choice for businesses aiming to minimize their environmental footprint.

galvanized metal mesh

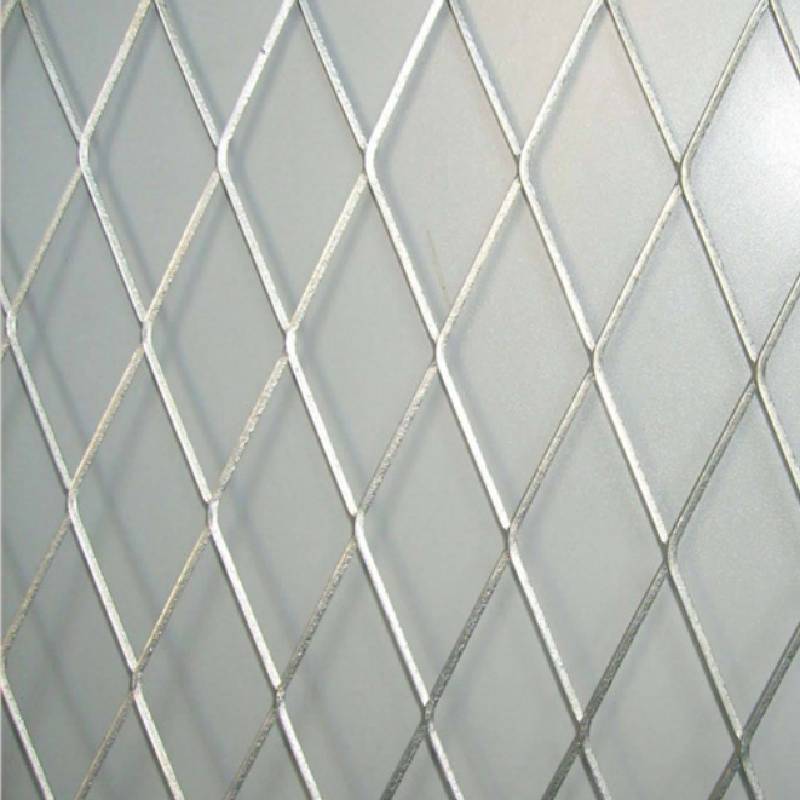

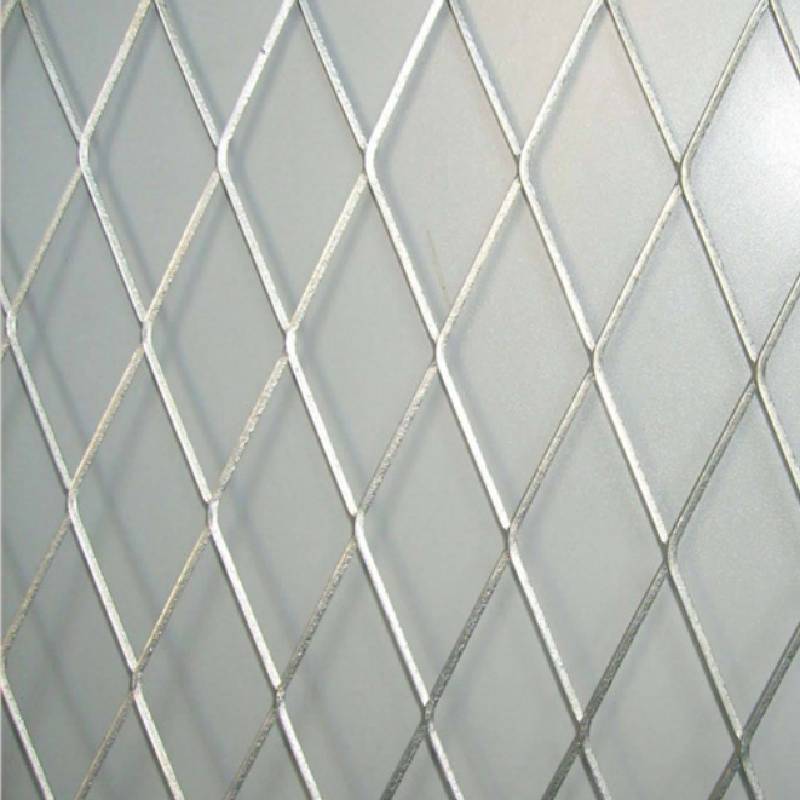

Professionals choosing galvanized metal mesh also recognize the intricate balance between rigidity and flexibility that the mesh offers. This quality is particularly useful in creative industries and the arts, where designers might use the mesh in innovative architectural designs or sculptures. The material’s ability to maintain shape while being adjustable to specific design needs demonstrates its adaptability.

Trust in galvanized metal mesh's reliability is reinforced by industry experts who endorse its usage based on empirical performance data and rigorous testing standards. Engineering professionals consistently turn to this mesh for projects that require superior strength without compromising on aesthetic appeal. Such endorsements not only highlight the efficacy of the material but also bolster confidence in its application across projects of varying scales.

The widespread acknowledgment of galvanized metal mesh’s efficacy is supported by certifications and standards that authenticate its use. Leading manufacturing processes adhere strictly to ISO standards to ensure that each product batch meets quality and safety expectations. Consumers and professionals alike value these certifications as they assure consistent and reliable performance.

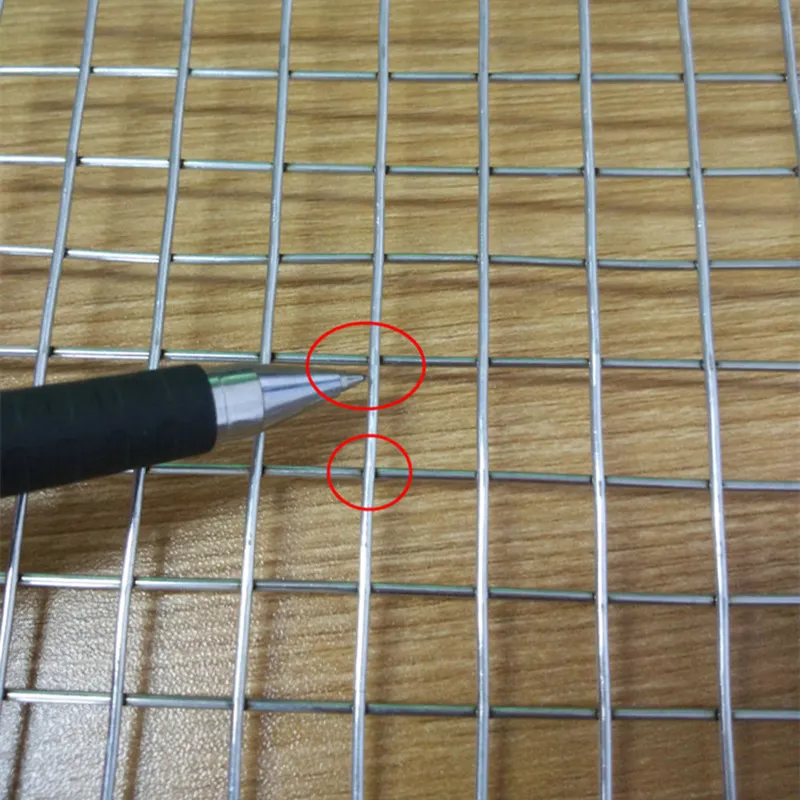

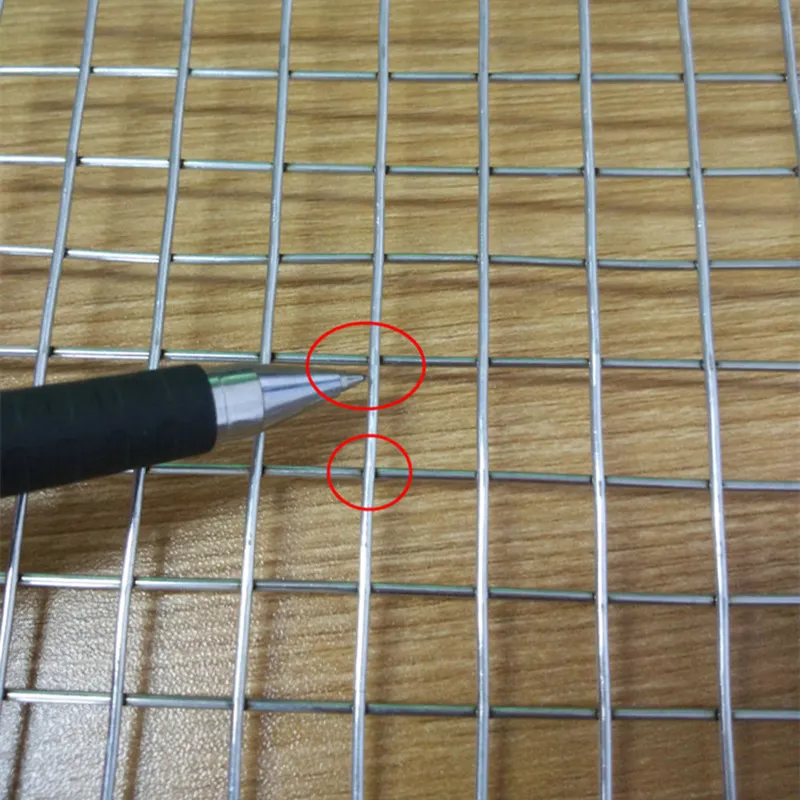

However, purchasing decisions should be informed by an understanding of varying grades and specifications to ensure optimal match for specific needs. Not all galvanized metal meshes are created equal. Factors such as the thickness of the wire, the size of the apertures, and the type of coating can drastically affect performance depending on the intended application.

In conclusion, galvanized metal mesh continues to prove its indispensability across a multitude of industries. Its combination of durability, versatility, and cost-effectiveness positions it as a top choice for professionals who seek materials that deliver high performance with minimal environmental impact. Through the endorsement by experts and adherence to strict manufacturing standards, galvanized metal mesh remains a trusted component in projects aimed at achieving resilience and sustainability.