Welding mesh fences have rapidly gained popularity in the realm of boundary setting and security enhancement. Their versatility, strength, and cost-effectiveness make them a preferred choice across various industries. As someone who has delved deeply into the construction and fencing industry for years, I can attest to the multifaceted benefits and applications of welding mesh fences.

First and foremost, the durability of welding mesh fences is unrivaled. Manufactured using robust steel wires, these fences undergo a precise welding process that ensures each intersection point is securely bonded. This results in a product that stands firm against environmental elements such as heavy rain, strong winds, and even the occasional impact. I recall consulting for a renowned agricultural firm in the Midwest where these fences withstood the harshest of winter storms without a single sign of compromise.

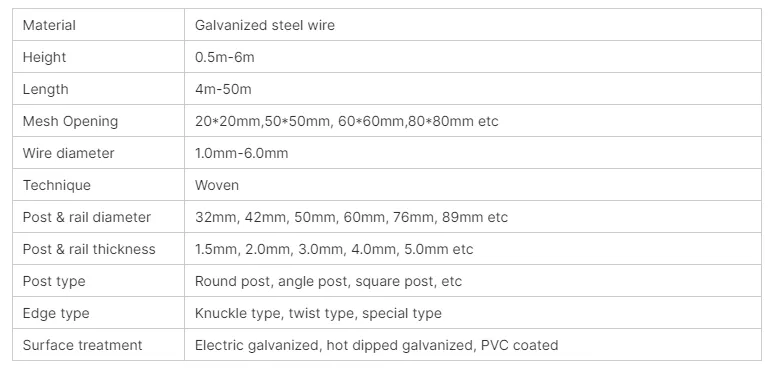

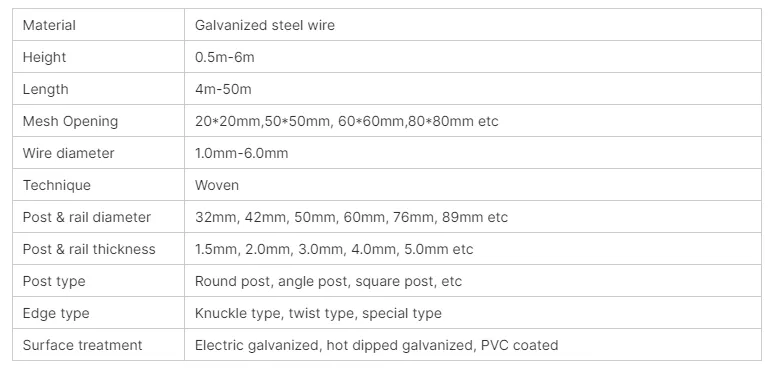

In terms of versatility, welding mesh fences are unmatched. They are customizable in mesh size, wire diameter, and even coating, allowing them to cater to diverse needs. Whether you need a small mesh size to keep out pesky rodents in a rural farm setting or a larger variant for delineating property boundaries in an urban environment, these fences can be tailored to fit the bill perfectly. I once assisted a zoo in selecting the right mesh size that offered both security for animals and visibility for visitors—a perfect blend of safety and visitor experience.

The ease of installation is another aspect where welding mesh fences shine. Typically available in panels or rolls, these fences require minimal tools and time for setup. A team of three can install substantial stretches in a matter of days, reducing labor costs significantly. My firsthand experience with an industrial site setup highlighted this advantage vividly, as the entire perimeter was secured in half the expected time, leading to operational savings and minimal disruptions.

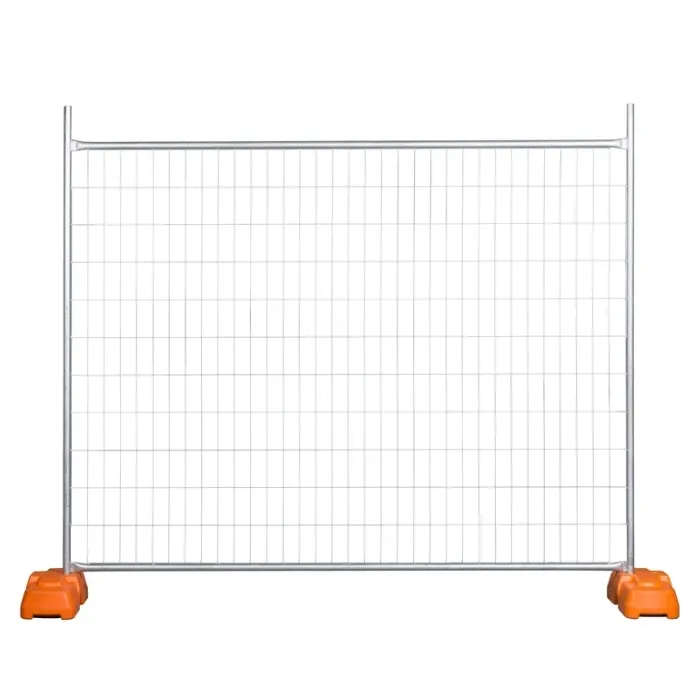

welding mesh fence

From a cost perspective, welding mesh fences offer great value. Their long lifespan, coupled with low maintenance needs, results in significant savings over time. Unlike traditional wooden fences that may rot or succumb to pest infestations, welding mesh panels maintain their integrity with minimal upkeep—a periodic wash and occasional inspection suffice to keep them in top condition. In an era where resource optimization reigns supreme, this cost-effectiveness cannot be overstated.

The security aspect of welding mesh fences is another feature that demands attention. Their sturdy build alone acts as a deterrent to potential intruders. Additionally, with options for increased height and electrification, these fences can be fortified to meet the highest security standards. In a previous role, I advised a high-security facility on upgrading their perimeter defenses, and the transition to welding mesh fences resulted in a notable decrease in breach attempts, underscoring their effectiveness.

Another benefit is the ecological footprint. As sustainability becomes a critical consideration, the fact that these fences are often made from recyclable materials adds another layer of appeal. Steel’s recyclability means that once a fence has outlived its usefulness, it doesn’t end up contributing to landfill waste—a significant plus for environmentally-conscious organizations and individuals alike.

In conclusion, the advantages of welding mesh fences extend far beyond mere boundary demarcation. Their unparalleled durability, customization options, and installation ease make them a superior choice for a spectrum of applications. As industries continue to evolve, so too will the use and functionality of these fences, ensuring they remain relevant in the ever-changing landscape of fencing solutions. With extensive experience and industry insight, I remain confident in recommending welding mesh fences as an optimal solution for security and demarcation needs.