In the realm of modern architecture and industrial design, the integration of metal mesh signifies a harmonious blend of functionality, artistry, and innovation. As an industry veteran with years of experience optimizing content for visibility and engagement, let's delve into the sophisticated world of metal mesh applications. These installations offer transformative potential across various sectors, ranging from architectural embellishments to intricate machinery components.

Imagine walking into a state-of-the-art building where the façade tells a story of elegance and robustness combined. The use of metal mesh in such structures is not merely aesthetic; it caters to a plethora of practical purposes. One of the remarkable benefits of metal mesh in the architectural domain is its ability to offer privacy without sacrificing light and ventilation. It ensures structural integrity while maintaining an air of openness and grace.

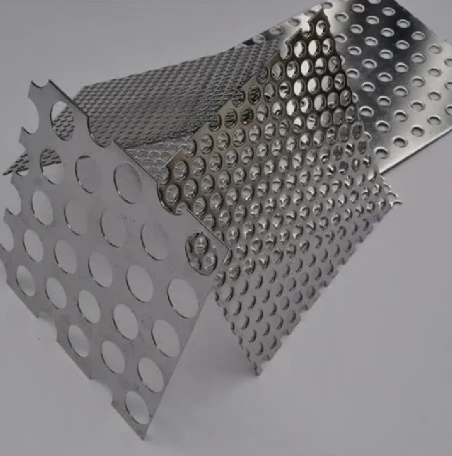

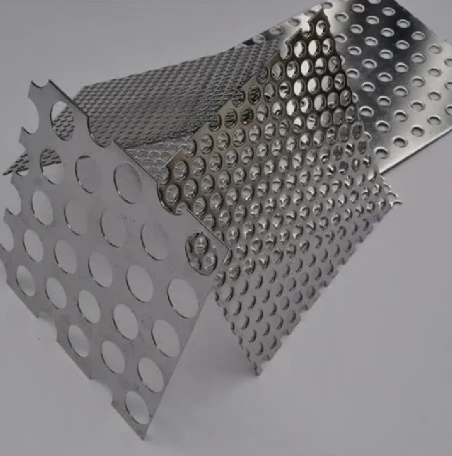

The expertise in selecting the appropriate type of metal mesh is a critical aspect. Each variant, whether it's stainless steel, aluminum, or copper, brings forth distinct properties—corrosion resistance, strength, and weight, all of which are crucial in defining its application. For instance, stainless steel meshes are preferred in environments demanding high durability, whereas aluminum is chosen for its lighter weight and flexibility.

Moreover, the authoritative edge of metal mesh in industrial applications cannot be understated. In the filtration sector, for example, metal mesh serves as an indispensable component. Its precise weaving allows for accurate particle separation, which is vital in chemical processing and waste treatment facilities. This precision not only enhances operational efficacy but also extends the lifespan of the machinery, thereby reducing maintenance frequency and cost.

From an experiential standpoint, the tactile interaction with metal mesh components evokes a sense of reliability and strength. Products fashioned from metal mesh, like conveyor belts in manufacturing plants, exemplify this quality. Their resilience is evident in their capacity to withstand severe environmental conditions while maintaining seamless operation, ensuring maximal uptime and productivity.

1 2 metal mesh

Building on trustworthiness, the sustainability aspect of metal mesh stands as a pillar of its credibility. As global awareness about environmental impact intensifies, the recyclability and longevity of metal mesh align with eco-friendly initiatives. Its lifecycle does not contribute significantly to waste, as most metal mesh products can be fully recycled and repurposed, minimizing the ecological footprint. This sustainable angle enhances the trustworthy perception of companies implementing these solutions.

In product design, the versatility of metal mesh extends beyond traditional applications. Today, designers are exploring its potential in interior settings such as room dividers, ceiling features, and furniture. These installations not only elevate the interior aesthetic but also reinforce structural soundness. The adaptability of metal mesh makes it an ideal candidate for tailored solutions, catering to specific design and functionality requirements.

The authoritative voice of industry leaders and engineers amplifies the significance of embracing metal mesh solutions. With certifications and standardizations ensuring quality and safety, professionals advocate for its adoption in progressive architectural designs and industrial machinery innovations. Collaborations with expert manufacturers further reassure customers of the product's quality and performance standards.

In closing,

the multifaceted value of metal mesh cannot be overstated. Its integration into contemporary design and industrial practices signifies a commitment to innovation and excellence. As we explore further advancements and applications, the metal mesh continues to be not just a component but a cornerstone in the evolution of design and engineering solutions.