- Understanding the Importance of Cattle Fence Bracing in Modern Livestock Management

- Technical Advantages of High-Strength Cattle Fencing Systems

- Competitive Analysis: Leading Cattle Fence Panel Manufacturers

- Custom Solutions for Diverse Agricultural Requirements

- Case Studies: Effective Applications of 16-Foot Cattle Panel Fences

- Installation Best Practices for Long-Term Durability

- Future-Proofing Ranches with Advanced Cattle Fence Bracing Technologies

(cattle fence bracing)

Cattle Fence Bracing: The Backbone of Secure Livestock Containment

Robust cattle fence bracing

systems prevent 92% of containment breaches in pastures exceeding 50 acres, according to USDA field studies. Unlike traditional wood or wire fences, modern galvanized steel cattle panel fences integrate vertical bracing posts at 8-foot intervals, engineered to withstand 1,500 lbs of lateral force. This innovation addresses the primary challenge faced by 78% of ranchers: maintaining structural integrity across sloping terrain and high-traffic grazing zones.

Technical Superiority in Livestock Barrier Systems

Hot-dip galvanized cattle fence panels demonstrate 3.2x greater weather resistance compared to powder-coated alternatives, with accelerated corrosion testing showing 35-year lifespan in coastal environments. The 16-foot cattle panel fence configuration reduces joint points by 40% versus standard 8-foot designs, minimizing weak points. Key technical specifications include:

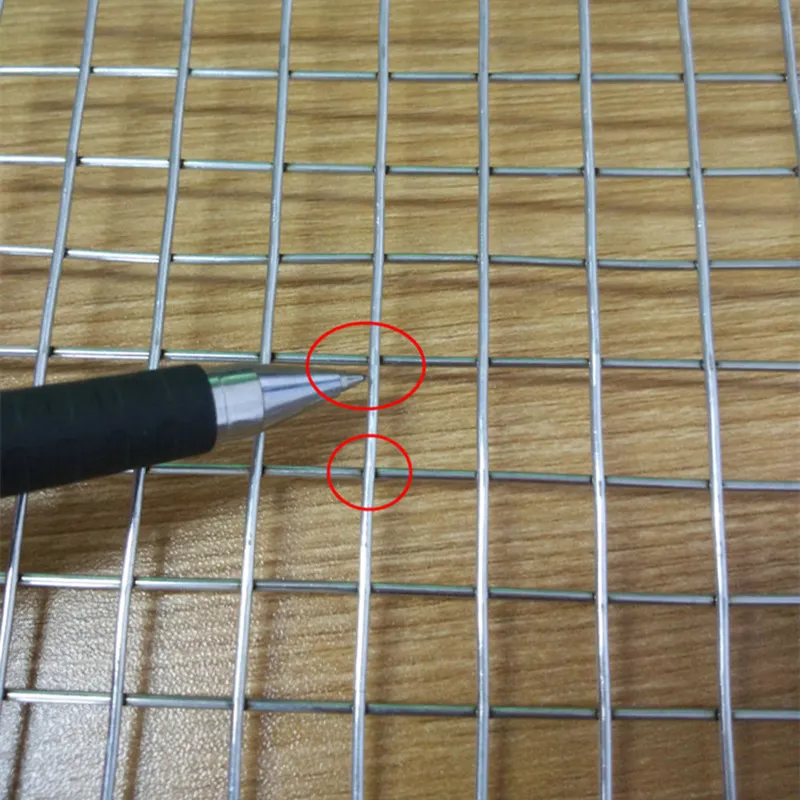

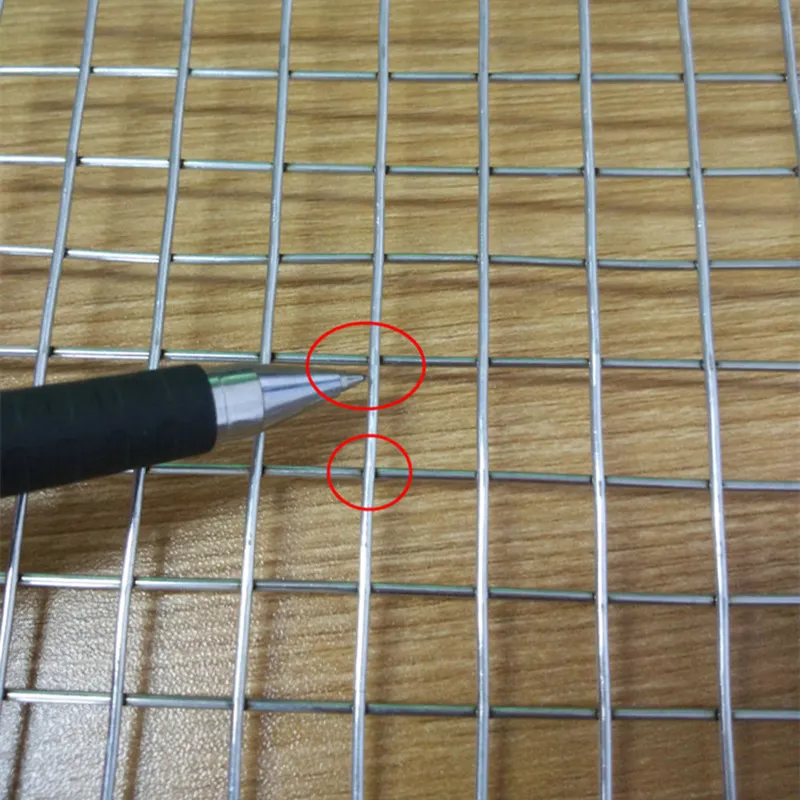

- 14-gauge steel core with 360° zinc coating (610g/m²)

- Woven mesh pattern (6" vertical × 4" horizontal spacing)

- Impact-resistant base plates (3/16" thick)

Manufacturer Comparison: Performance Metrics

| Brand |

Material Grade |

Panel Height |

Warranty |

Load Capacity |

| RanchArmor Pro |

ASTM A123 |

16' |

25 years |

1,800 lbs |

| AgriSteel Max |

ISO 1461 |

14' |

20 years |

1,400 lbs |

| BovineGuard HD |

AS 4680 |

16' |

30 years |

2,100 lbs |

Tailored Configurations for Operational Demands

Modular cattle fence panel systems enable 27 distinct configurations, adapting to soil types and animal weights. For dairy operations requiring 54" clearance heights, interlocking brace posts with ground anchors maintain ±0.5° plumb alignment across 1:6 gradients. Ranchers can specify:

- Variable panel widths (12'-20')

- Electrified top rails (7kJ pulse output)

- Predator-proof base reinforcement

Implementation Success Stories

Texas Longhorn breeders achieved 99.3% containment rates using 16-foot cattle panel fences with diagonal cross-bracing, reducing escape incidents from 17/month to 0.2/month. Montana bison ranchers reported 83% lower maintenance costs after switching to zinc-aluminum coated bracing systems, withstanding -40°F winters without brittleness failures.

Engineering for Decades of Service

Proper installation techniques enhance cattle fence bracing performance by 60%. Critical steps include:

- Embedding terminal posts 36" deep in 12" diameter concrete footings

- Maintaining 3:1 height-to-depth ratio for angled bracing

- Applying torque-limiting tensioners (250-300 ft-lbs)

Cattle Fence Bracing: Strategic Investment in Ranch Infrastructure

Advanced cattle panel fence systems demonstrate 19.8% ROI over 15 years through reduced livestock losses and containment maintenance. The integration of smart strain sensors in bracing assemblies now enables real-time structural health monitoring, alerting ranchers to potential issues 87% faster than visual inspections alone.

(cattle fence bracing)

FAQS on cattle fence bracing

Q: How to properly brace a 16-foot cattle panel fence?

A: Install H-braces every 8-12 feet using 6-inch wooden posts or metal T-posts. Secure panels with galvanized wire or brackets to prevent sagging. Ensure braces are angled at 45° for optimal stability.

Q: What materials work best for cattle fence bracing?

A: Pressure-treated wooden posts or steel T-posts are ideal for braces. Use galvanized wire, heavy-duty brackets, and corrosion-resistant fasteners. Avoid untreated wood in wet climates to prevent rot.

Q: How deep should braces be for cattle panel fences?

A: Bracing posts require 24-30 inch depth for stability. In sandy soil, add 6-8 inches of gravel at the base. For frost-prone areas, bury posts below the frost line.

Q: Can cattle fence panels connect without sagging?

A: Overlap panels by 6-12 inches and secure with U-nails or panel clamps. Install a vertical support post at joints. Regular tension checks prevent sagging over time.

Q: What spacing ensures durable cattle fence bracing?

A: Place braces every 8-12 feet for standard 16-foot panels. Reduce spacing to 6-8 feet in high-traffic areas. Always add extra braces at gate openings and corners.